4.2 MONORAIL Guide Rail Types

4.2.1 Characteristics

Depending on the application, different requirements are placed on the SCHNEEBERGER MONORAIL guide rails. The advantages of roller guides apply primarily to applications that require high load capacity and rigidity as well as extended service life, or applications where installation space is limited.

Due to lower moving mass, the advantages of ball guides are found in dynamic applications, in other words, at high speeds and accelerations or increased requirements for noise accumulation and thrust forces. Otherwise, they have cost advantages compared to roller types, and due to their wider selection of structural shapes, can be optimally adapted to structural conditions.

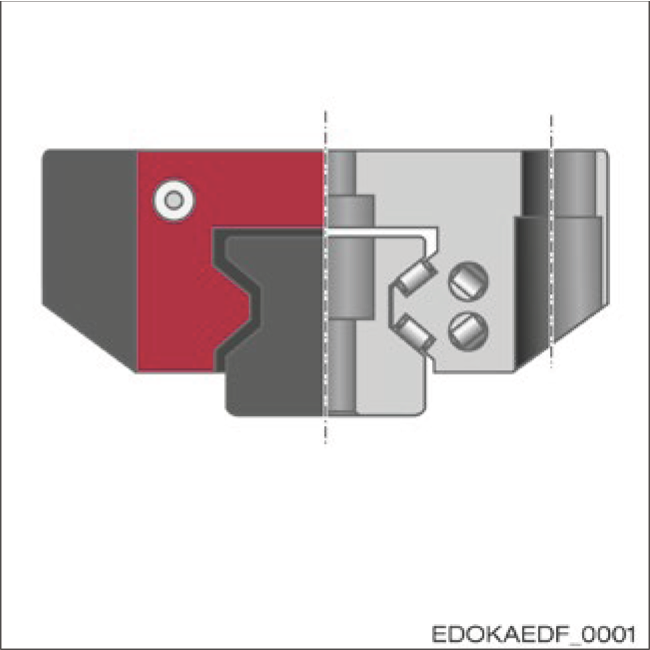

MONORAIL MR Roller Guides

Technical Characteristics

- 4 raceways, O-geometry, rollers with spherical surfaces

- Fully sealed carriages

- Main dimensions conform to DIN 645-1

- Wide range of design and lubrication options

- Numerous accessories for various applications

Main Application Areas

Machine tools with high cutting performance and extended service life, machines/equipment with very small installation dimensions, CNC machining centers, CNC lathes, CNC grinding machines, EDM machines, injection molding machines

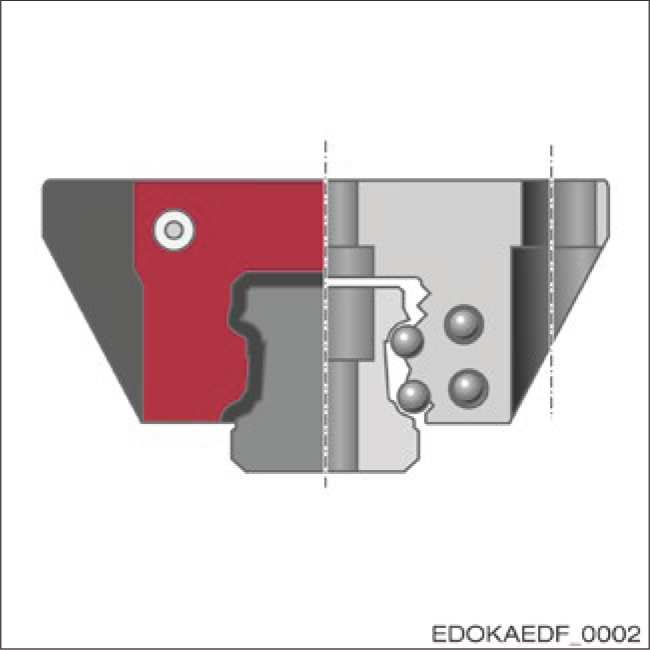

MONORAIL BM Ball Guides

Technical Characteristics

- 4 rows of balls, O-geometry, 2-point contact

- Optimized raceway geometry with reduced number of transition points

- Low number of parts

- Integrated lubricant reservoir for reduced maintenance

- Fully sealed carriages

- Trapezoidal guide rail profile with high rigidity and easy replacement of wear parts

- Main dimensions conform to DIN 645-1

Main Application Areas

Machine tools with small to medium cutting performance, secondary axes, woodworking machinery, sheet metal processing machinery, waterjet/laser cutting systems, automatic punch presses, robotics, handling devices and automation technology, electronics and semiconductor technology, measurement technology, medical technology

Characteristics Comparison

| Characteristic | MONORAIL MR Roller Type | MONORAIL BM Ball Type |

|---|---|---|

| Load Capacity | ||

| Rigidity | ||

| Accuracy | ||

| Service Life | ||

| Running Characteristics/Pulsation | ||

| Friction Behavior | ||

| Permissible Speed | ||

| Installation and Maintenance | ||

| Accuracy and Rigidity Requirements for Surrounding Structure | High | Medium |

| Integrated Distance Measuring System | Yes | Yes |

| Integrated Rack | No | Yes |

4.2.2 Application Areas

Roller Guides

Roller guides are typically used in:

- Machine tools with high cutting performance and extended service life

- Machines/equipment with very small installation dimensions

- Machining centers

- Drilling centers

- CNC lathes

- CNC grinding machines

- EDM machines

- Injection molding machines

- Forming technology

Ball Guides

Ball guides are used, for example, in:

- Machine tools with small to medium cutting performance

- Secondary axes

- Woodworking machinery

- Sheet metal processing machinery

- Waterjet and laser cutting systems

- Automatic punch presses

- Robotics

- Handling equipment and automation technology

- Electronics and semiconductor technology

- Measurement technology

- Medical technology