不同的應用領域需要線性導軌和循環單元的不同特性。

產品選擇時需要考慮多種參數和因素。以下詳細說明這些關鍵考量。

行程 H 與導軌長度 L 的關係

Relationship between stroke H and length of the guideway L

行程 < 400 mm

If the stroke is below 400 mm

行程 > 400 mm

If the stroke is above 400 mm

| L | = 線性導軌長度 (mm) Length of the linear guideway in mm |

| H | = 可能行程 (mm) Possible Stroke in mm |

計算滑塊長度 K

Calculating the cage length K

對稱行程

If the stroke is symmetrical

非對稱行程

If the stroke is asymmetrical

H > H₁ + H₂

H₁₂ = H₁ + H₂

| K | = 滑塊長度 (mm) Cage length in mm |

| L | = 線性導軌長度 (mm) Length of the linear guideway in mm |

| H | = 可能行程 (mm) Possible Stroke in mm |

| H₁ | = 大部分行程 = H/2 (mm) Large partial stroke in mm = H/2 |

| H₂ | = 小部分行程 = H/2 (mm) Small partial stroke in mm = H/2 |

| H₁₂ | = 有效部分行程 (mm) Effective partial stroke in mm |

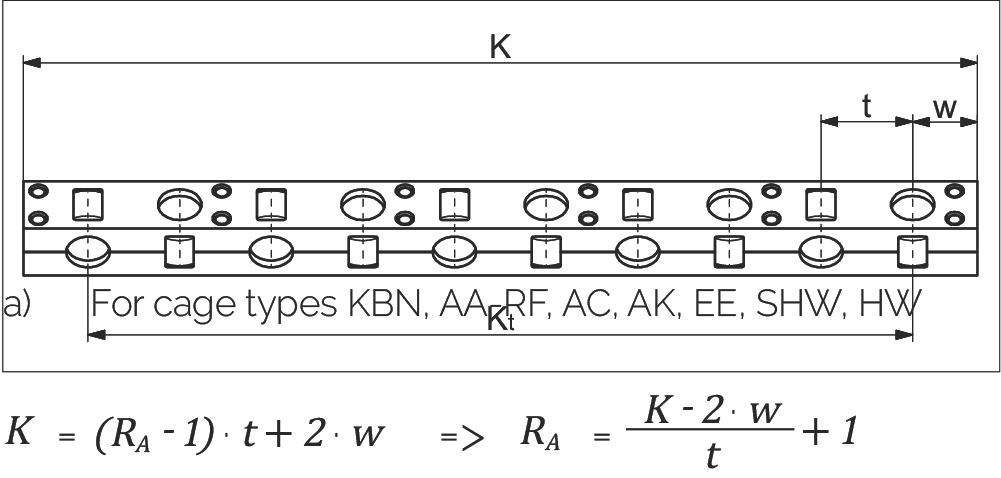

計算每個滑塊的滾動元件數量 (RA)

Calculating the number of rolling elements (RA) per cage

a) 滑塊類型:KBN, AA-RF, AC, AK, EE, SHW, HW

For cage types KBN, AA-RF, AC, AK, EE, SHW, HW

或

b) 滑塊類型:KBS

For cage type KBS

或

| K | = 滑塊長度 (mm) Cage length in mm | t | = 滑塊分度 (mm) cage division in mm |

| RA | = 每個滑塊的總可用滾動元件數 Total available rolling element per cage | Kt | = 負載長度 (mm) Load-bearing length in mm |

| w | = 從滑塊起始到第一個滾動元件中心的距離 (mm) Distance from cage start to the middle of the first rolling element in mm | tz | = KBS 滑塊中間段的長度 (mm) Length of the middle section for the KBS cage |

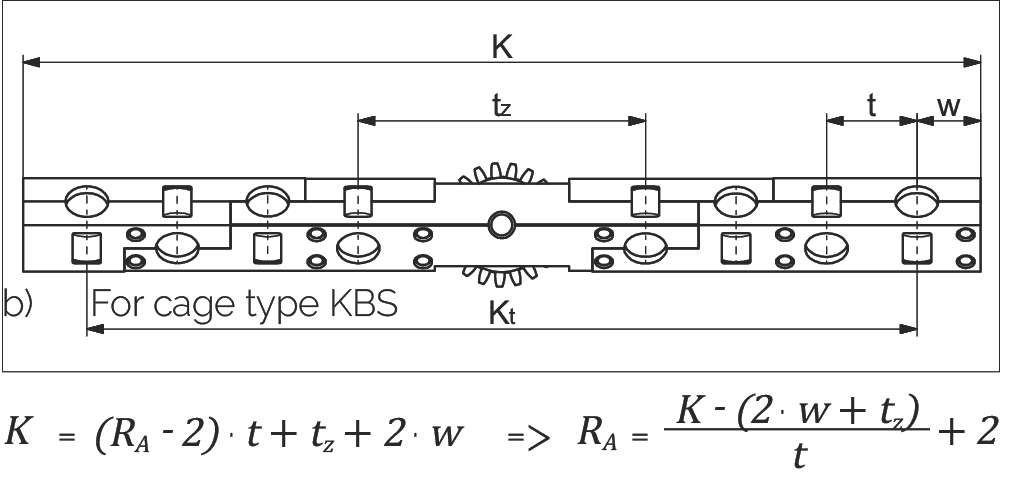

滑塊長度 K 與平均導軌間距 Q 的關係

The relationship between the cage length K and the average guideway spacing Q

| K | = 滑塊長度 (mm) Cage length in mm |

| Q | = 平均線性導軌間距 (mm) Average linear guideway spacing in mm |

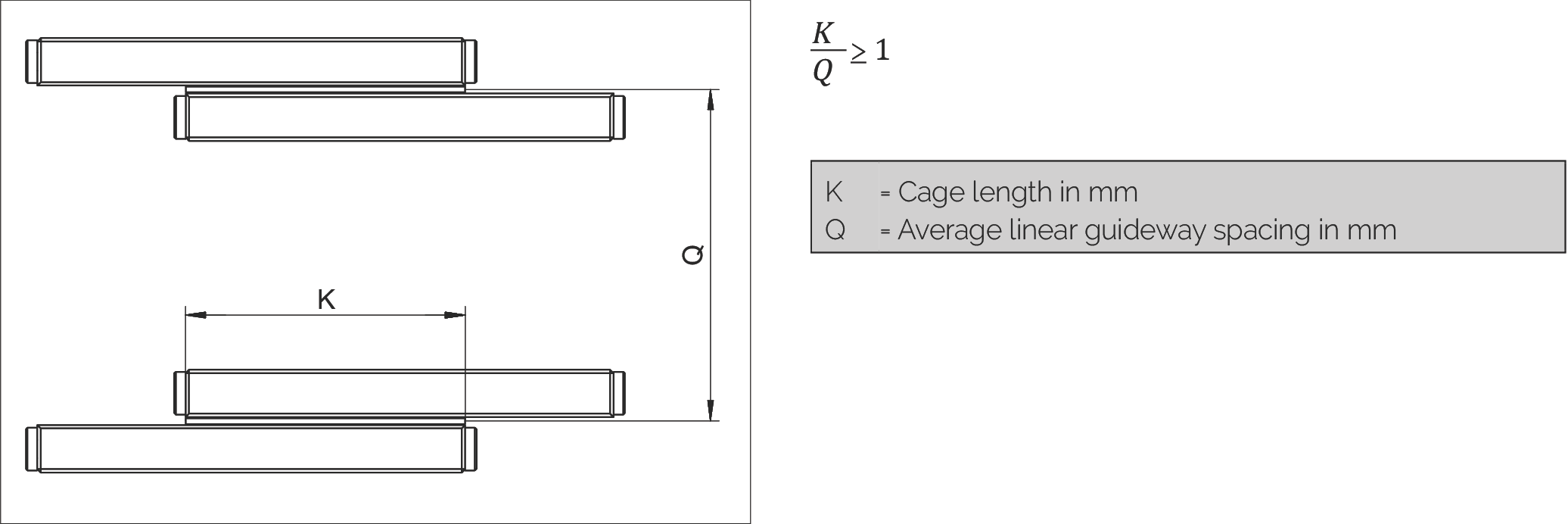

超行程滑塊的最大允許安裝比例

The maximum permissible installation ratio in the case of overrunning cages

當需要在長導軌軌道上移動短工作台時,超行程滑塊是一種有效的解決方案。在這種情況下, 導軌的短軌必須配備圓形導入部(特殊版本 EG,參見第 7.3 章),以使超行程滑塊產生的脈動盡可能小。

最大允許安裝比例 L : L₁

Maximum permitted installation ratios L to L₁:

| 固定式導軌 for fixed guideways | 1 : 2 |

| 疊置式導軌 for laid on guideways | 1 : 4 |

線性導軌的安裝變體

Installation variants for linear guideways

線性導軌有四種安裝變體。各種線性導軌也可以使用端件形式的刮水器 (a₁)*。 在這四種情況下,會產生以下長度比率:

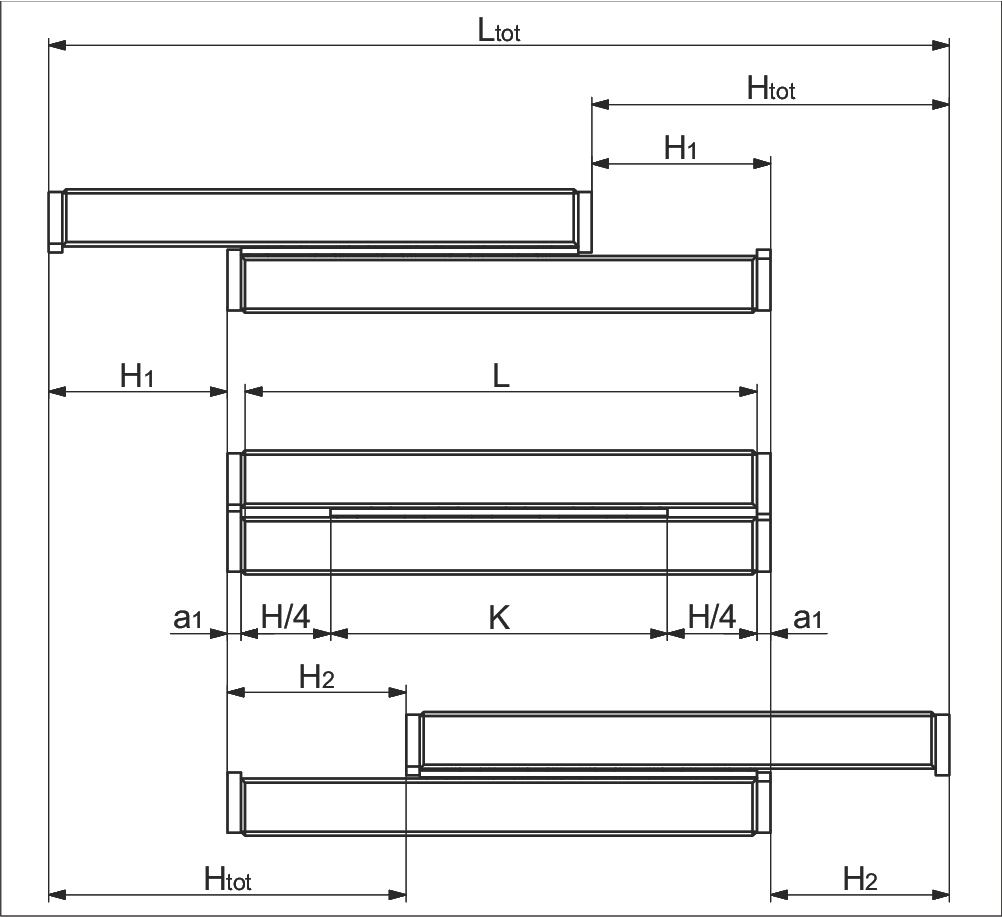

變體 1

- 等長軌道

- 對稱/非對稱行程

a) 無端螺絲、端件和刮水器端件

Without end screws, end pieces, and end pieces with wipers

b) 配備端螺絲、端件和刮水器端件**

For end screws, end pieces, and end pieces with wipers**

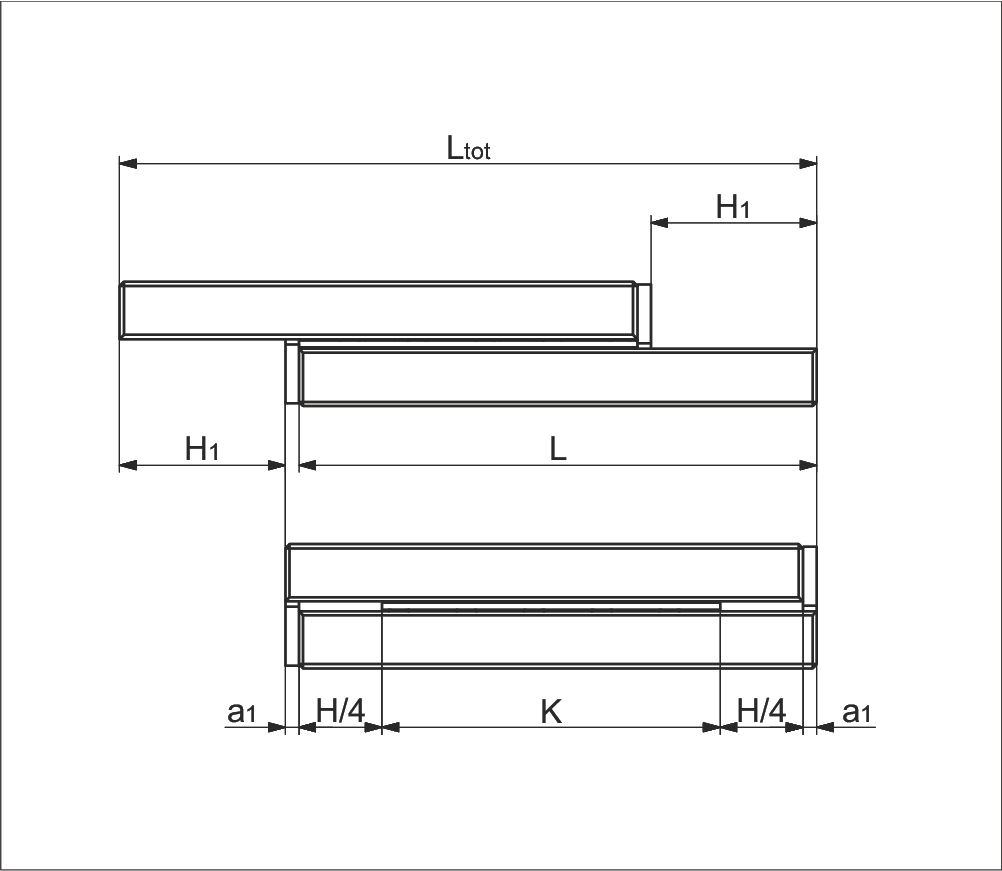

變體 2

- 等長軌道

- 單向行程

a) 無端螺絲、端件和刮水器端件

Without end screws, end pieces, and end pieces with wipers

b) 配備端螺絲、端件和刮水器端件**

For end screws, end pieces, and end pieces with wipers**

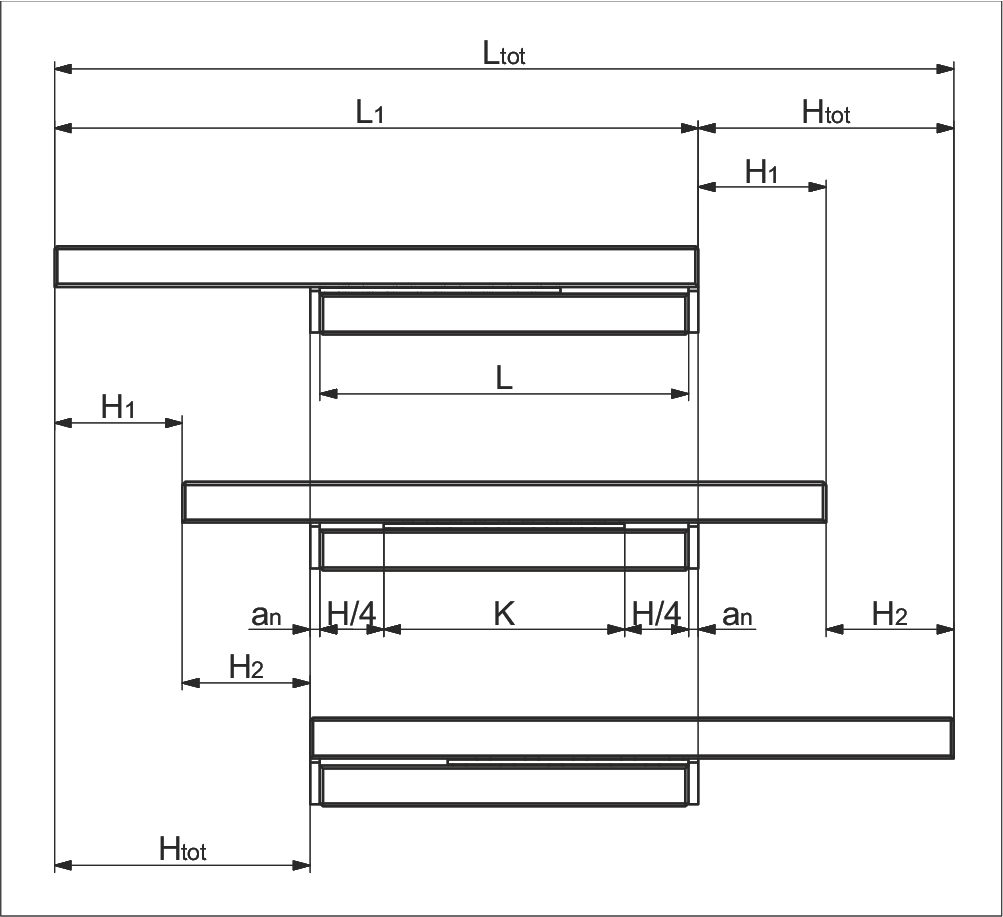

變體 3

- 不等長軌道

- 對稱/非對稱行程

- 短軌附加

a) 無端螺絲、端件和刮水器端件

Without end screws, end pieces, and end pieces with wipers

b) 配備端螺絲、端件和刮水器端件**

For end screws, end pieces, and end pieces with wipers**

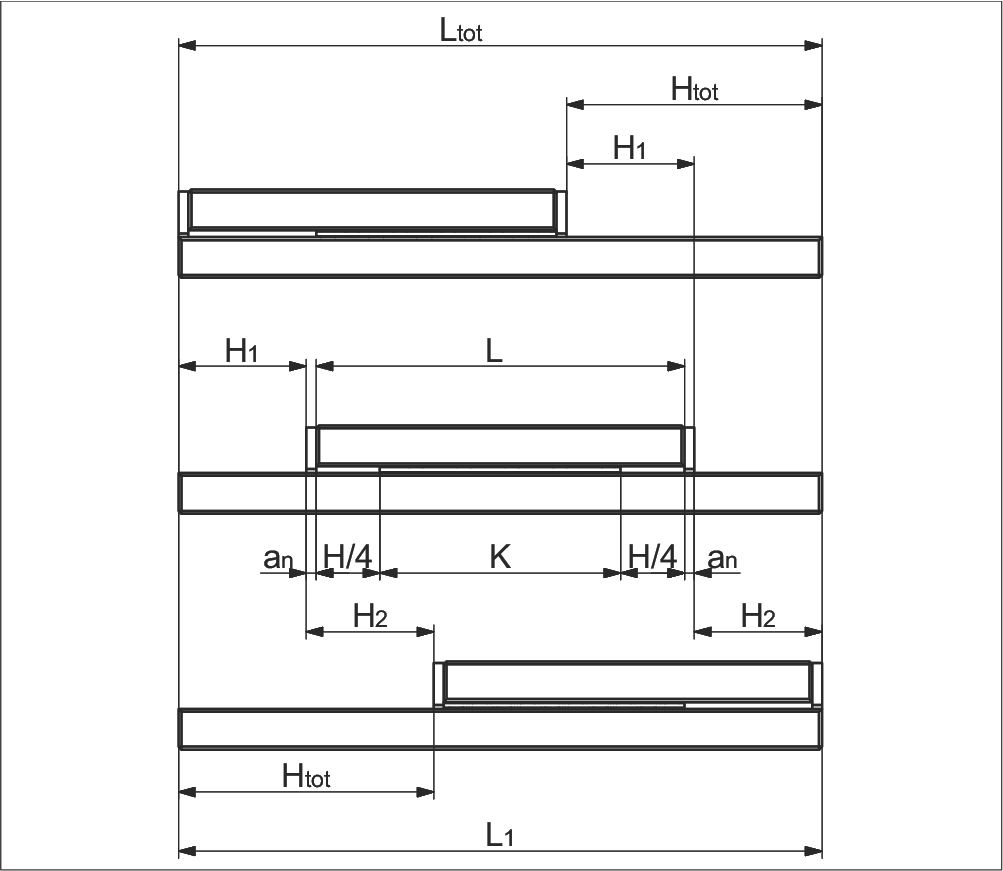

變體 4

- 不等長軌道

- 對稱/非對稱行程

- 長軌附加

a) 無端螺絲、端件和刮水器端件

Without end screws, end pieces, and end pieces with wipers

b) 配備端螺絲、端件和刮水器端件**

For end screws, end pieces, and end pieces with wipers**

參數說明

| K | = 滑塊長度 (mm) Cage length in mm | H | = 可能行程 (mm) Possible stroke in mm |

| H₁ | = 大部分行程 = H/2 (mm) Large partial stroke in mm = H/2 | H₂ | = 小部分行程 ≤ H/2 (mm) Small partial stroke in mm ≤ H/2 |

| Htot | = 有效部分行程 (mm) Effective partial stroke in mm | H12 | = 總部分行程 = H1 + H2 (mm) Total partial stroke in mm = H1 + H2 |

| L | = 導軌長度 (mm) Length in mm | L₁ | = 長軌長度 (mm) Length in mm |

| Ltot | = 總長度 (mm) Total length in mm | an | = 端件厚度 (mm) Thickness of the end piece in mm |

* a₁ 端螺絲、端件和刮水器端件,見第 5 章

** 刮水器可能會影響線性導軌的運行特性