Fastening Methods

myonic offers the following fastening methods for AXCR-U / AXCR-S in the standard series:

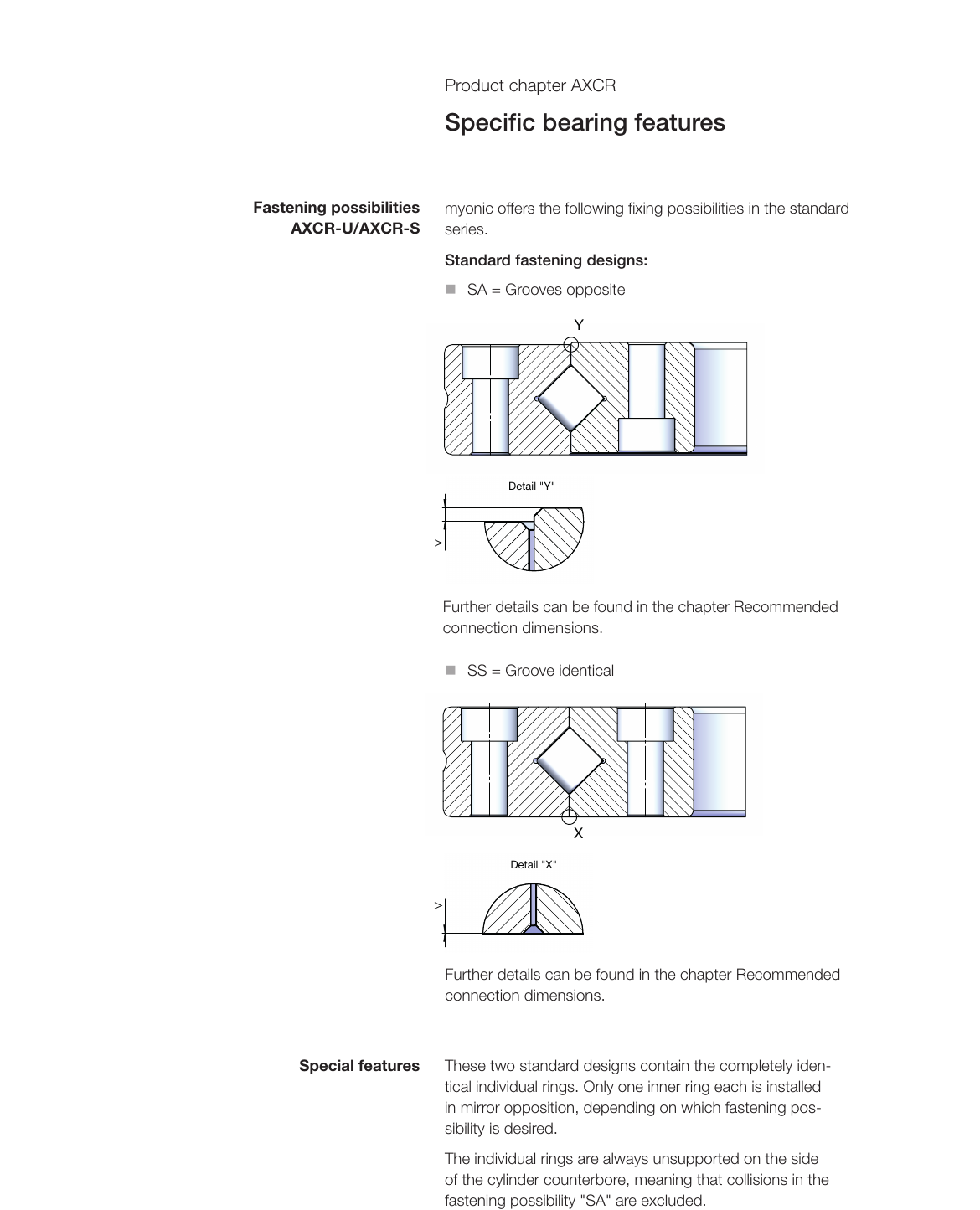

Standard Fastening Designs

| Code | Design Name | Description |

|---|---|---|

| SA | Grooves Opposite | The fastening grooves of inner and outer rings are on opposite sides. The countersunk holes are always unsupported on the cylindrical counterbore side, meaning "SA" excludes the possibility of fastening. |

| SS | Grooves Identical | The fastening grooves of inner and outer rings are on the same side. Since the countersunk holes face the same direction, the overall height is lower. |

Note

More detailed information can be found in the "Adjacent Construction Design" section.

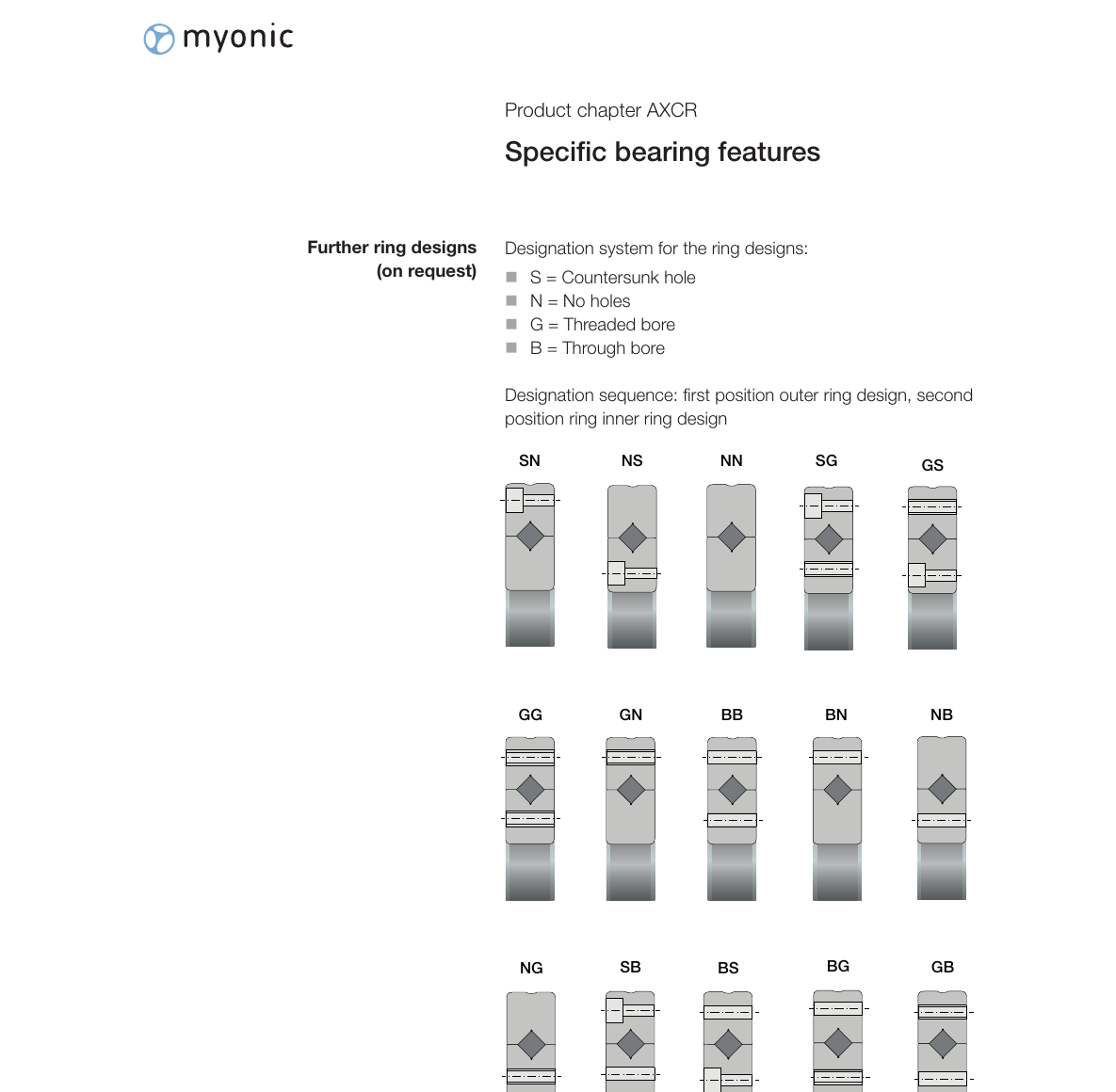

Ring Design System

The designation system for ring designs is as follows (available upon request):

| Code | Design Type | Description |

|---|---|---|

| S | Countersunk Hole | Countersunk hole - mounting hole with countersink |

| N | No Holes | No holes - no mounting holes on the ring |

| G | Threaded Bore | Threaded bore - mounting hole with internal thread |

| B | Through Bore | Through bore - smooth through mounting hole |

Designation Order

Designation order: First position = outer ring design, Second position = inner ring design

Example: SN = outer ring with countersunk hole, inner ring with no holes

Ring Design Combinations

The following are common ring design combinations (designation order: first position = outer ring design, second position = inner ring design):

Example: SG

- First position S: Outer ring design is countersunk hole

- Second position G: Inner ring design is threaded bore

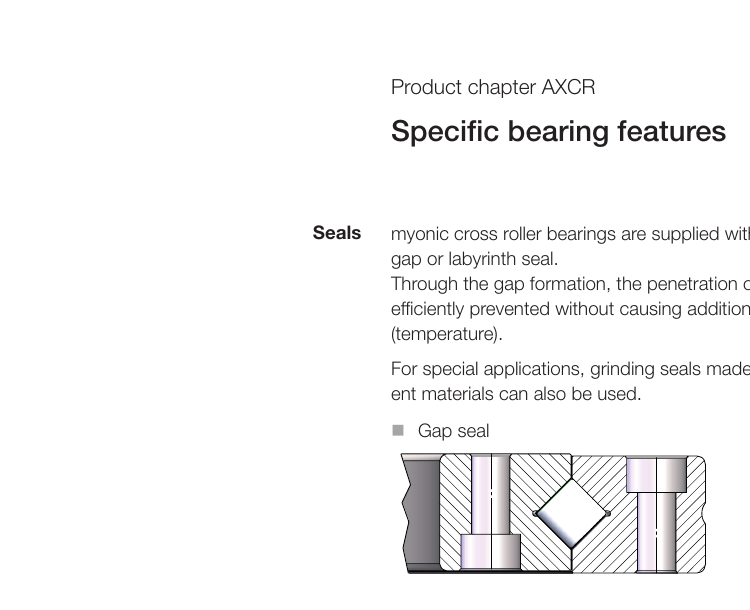

Seals

myonic cross roller bearings are equipped as standard with non-ground gap seals or labyrinth seals.

Gap Seal Features

- Formed by gaps, effectively prevents dust particle penetration

- Does not cause additional friction (temperature)

- Suitable for most standard applications

For special applications, ground seals made from various different materials can be used.

Accuracy

myonic production is performed on the same production system as all other ultra-precision bearings. This way, myonic AXCR cross roller bearings can achieve similar accuracy to AXRY or AXCR bearings.

The measuring accuracy P6 for bore and outer diameter allows for the production of high-precision fits, enabling precise guidance of the rotating axis.

Accuracy Grades

| Accuracy Parameter | Description | Grade |

|---|---|---|

| Axial Runout | Axial runout | P4, P2, UP optional |

| Radial Runout | Radial runout | P4, P2, UP optional |

The axial and radial runout accuracy of AXCR-U and AXCR-M corresponds to grades P4, P2 and UP. With AXCR-S, you can choose between standard and restricted runout accuracy (PRR50).

More Information

For detailed accuracy information, please refer to the product tables.

Lubrication

AXCR bearings can be lubricated with grease or oil. The standard configuration is grease lubrication.

| Lubrication Type | Description | Application |

|---|---|---|

| Grease Lubrication | Standard configuration, lifetime lubrication | Most standard applications |

| Oil Lubrication | Requires continuous oil supply system | High speed or high temperature applications |

Preload

myonic cross roller bearings are available in bearing clearance, light preload and standard preload versions.

| Preload Type | Characteristics | Application |

|---|---|---|

| Bearing Clearance | Clearance between rollers and raceways | Special application requirements |

| Light Preload | Lower friction torque | Applications requiring lower friction |

| Standard Preload | Higher rigidity with increased friction torque | Most standard applications |

With higher preload, rigidity increases; at the same time, bearing friction torque also increases. Generally, most AXCR bearings are assembled with standard preload.

Customer-specific Designs (J-numbers)

myonic produces customer-specific bearing designs, designated with J and a number.

Such J-numbers can include the following:

- Application-specific preload values or friction torque

- Special instructions for marking or packaging

- Special lubrication systems

- Modified tolerances

Note

J-numbers are assigned by myonic. For customized designs, please contact the myonic application engineering team.

Preservatives

The anti-corrosion protection oil used is compatible with most greases and oils produced on a mineral oil basis.

When using synthetic lubricants and thickeners other than lithium (complex) soaps, please check compatibility. In case of incompatibility, please consult myonic for further procedures.

Standard Series: myonic cross roller bearings in the standard series do not receive surface treatment.

Surface Treatment

myonic cross roller bearings in the standard series do not receive surface treatment.

In case of incompatibility, please consult myonic for further procedures.

Limiting Speeds / Temperatures / Friction

The limiting speeds stated in the dimension tables can be achieved in short-term or long-term continuous operation of the selected cross roller bearing.

Operating Condition Notes

- During extended operation and near the limiting speed range, bearings will gradually "heat up"

- Higher preload leads to higher rigidity with higher friction

- The friction torque of cross roller bearings is mainly influenced by the selected preload

Relubrication

The selected lubricant, particularly its viscosity and filling quantity, has a direct influence on friction. Standard pre-lubricated bearings are suitable for medium-speed operation and shorter continuous operation up to limiting speeds.

Lubrication systems are best suited for relubrication purposes. In the case of manual relubrication, there is a risk of over-lubrication.

Warning

During break-in or relubrication, adequate break-in running time is appropriate, and direct high-speed operation should be avoided.

Calculation of Rigidity

Rigidity calculations are performed under the following parameters:

- Application of radial and axial loads as well as fitting moments

- Light preload

- Normal adjacent construction and screw connections (according to myonic catalog information)

In all product groups, the same FEM calculation procedure with precisely defined parameters is used. The rigidity values stated in the product tables can be directly compared (e.g., AXRY vs. AXCR vs. AXCR).

Adjacent Construction Influence

Undersized, imprecise adjacent construction significantly reduces the rigidity at the bearing position; on the other hand, rigidity can be increased through supported continuous adjacent construction.

For detailed information, please refer to the "Machine Tool Bearing General Technology" section.

Next Steps

Learn more about AXCR bearing technical information:

- Limiting Load Diagrams - Static limiting load diagrams for each size series

- Recommended Shaft Fits - Shaft fit tolerance selection guide

- Recommended Housing Fits - Housing fit tolerance selection guide