The following example calculations illustrate the procedure for handling some typical problems.

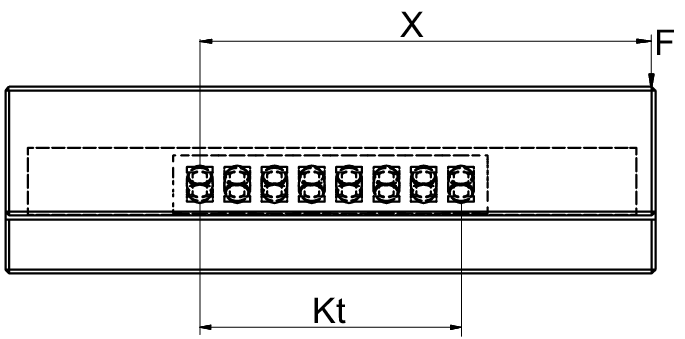

Example 1: Equivalent Load P per Roller

Assumptions:

- Linear guides type R 6

- AC 6 cage with 8 rollers (RA = 8)

- Load F = 350 N

- Lever arm distance X = 120 mm

For AC 6 type roller cage, the following applies:

Step 1: Calculate load-bearing length Kt

Step 2: Determine correction factor

Rtmin = 1 roller (according to chapter 5.1 AC 6 cage technical specifications)

C = 530 N (max. permissible load capacity per roller)

Step 3: Calculate equivalent load P per roller

✓ P (334 N) is less than C (530 N), therefore this design is correct.

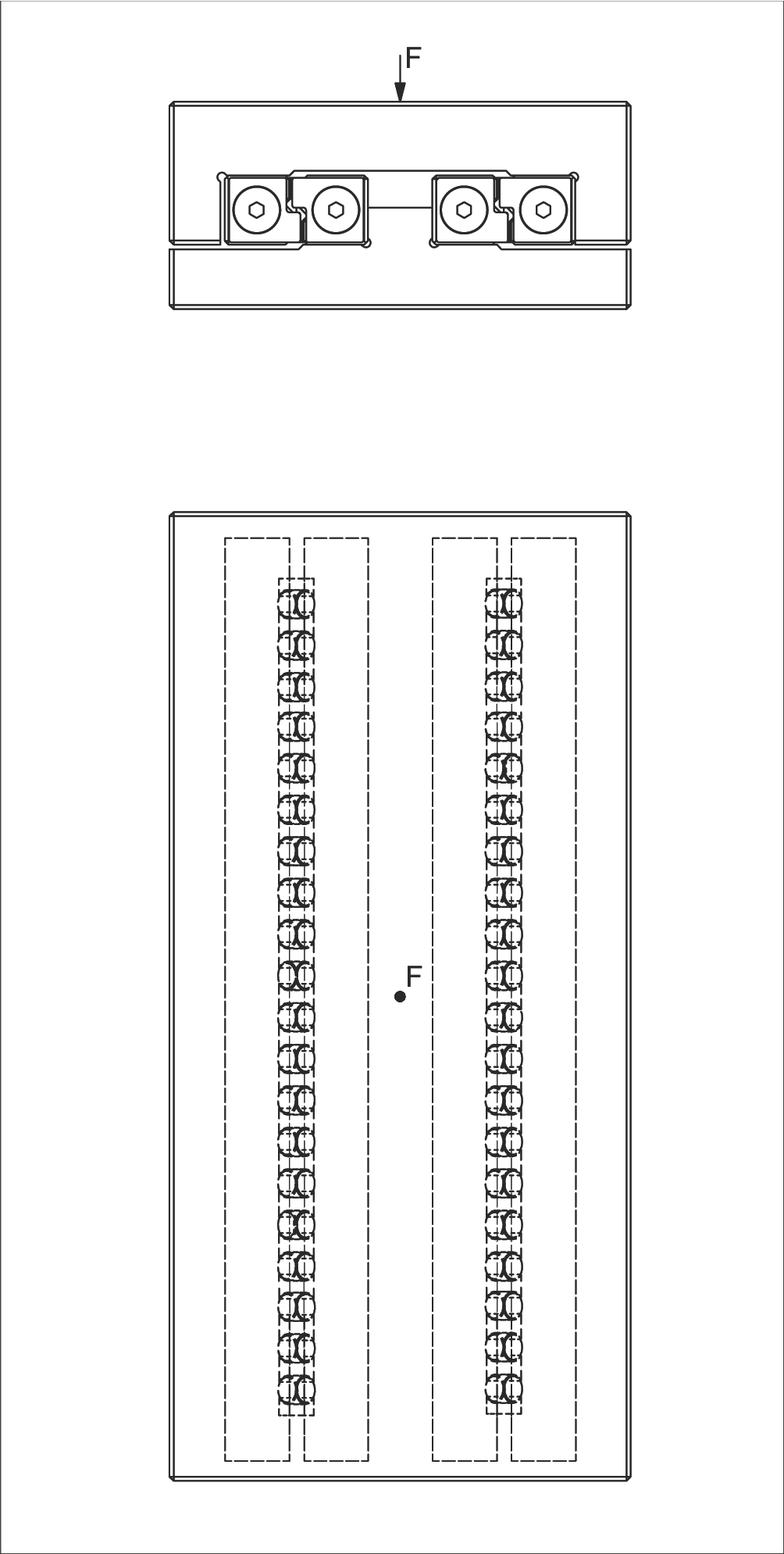

Example 2: Equivalent Load P per Roller (20 Rollers)

Assumptions:

- Linear guides type R 6

- AC 6 cage with 20 rollers (RA = 20)

- Load F = 6,500 N (acting vertically on dual guideway system)

- C = 530 N (max. permissible load capacity per roller)

Calculation Steps:

Step 1: Calculate number of load-bearing rollers

Since the load acts vertically, each guideway in the dual system bears half the load.

Step 2: Calculate equivalent load P per roller

✓ P (325 N) is less than C (530 N), therefore this design is correct. Safety factor = 530 / 325 ≈ 1.63

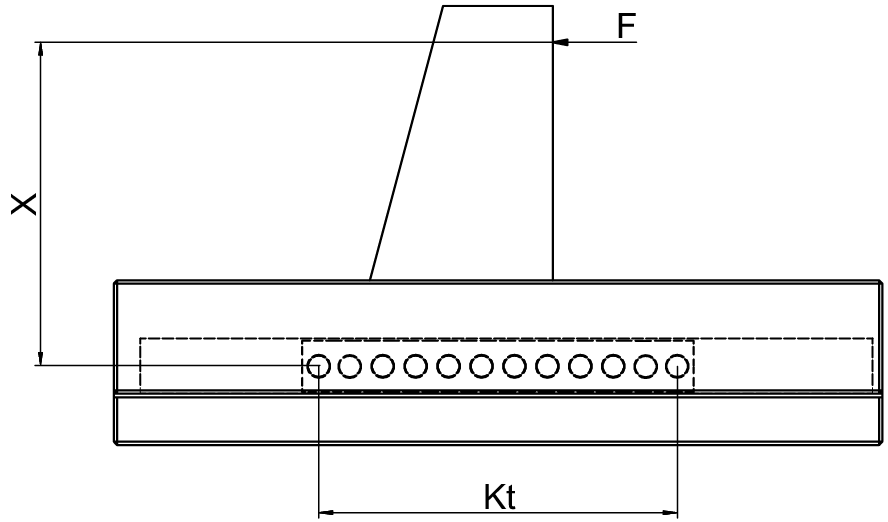

Example 3: Equivalent Load P per Ball

Assumptions:

- Rigid cage structure

- Linear guides type R 6

- AK 6 cage with 12 balls (RA = 12)

- Cage division t = 9 mm

- Load F = 240 N

- Lever arm distance X = 75 mm

- C = 65 N (max. permissible load capacity per ball)

Calculation Steps:

Step 1: Calculate load-bearing length Kt

Step 2: Determine correction factor Rtmin

According to the Rtmin calculation chart in chapter 12.3:

- Structure type: Rigid structure (A)

- X/Kt = 75/99 = 0.76 (less than 1)

- From chart: Rtmin ≈ Rt/2

Step 3: Calculate equivalent load P per ball

✓ P (30.3 N) is less than C (65 N), therefore this design is correct. Safety factor = 65 / 30.3 ≈ 2.15

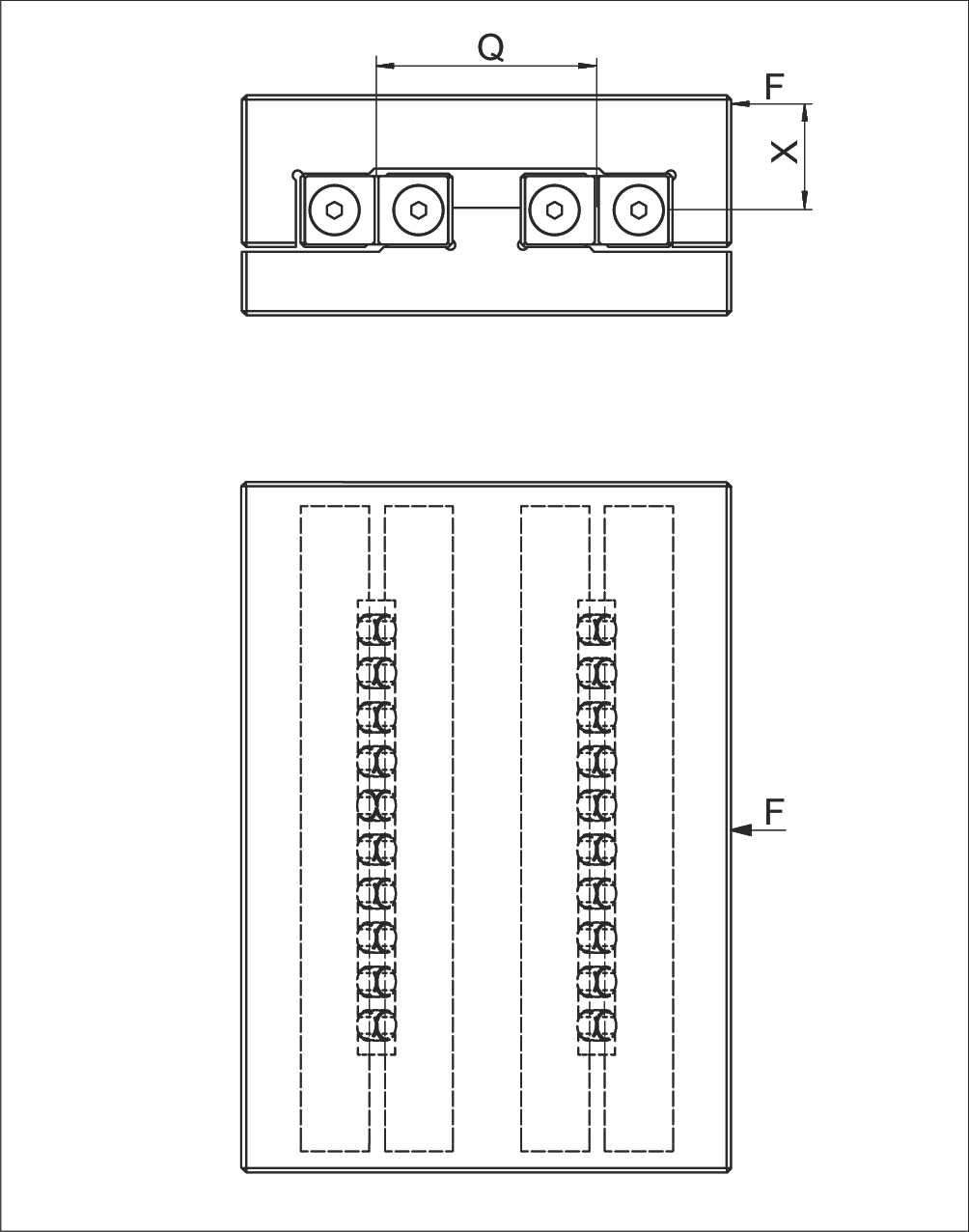

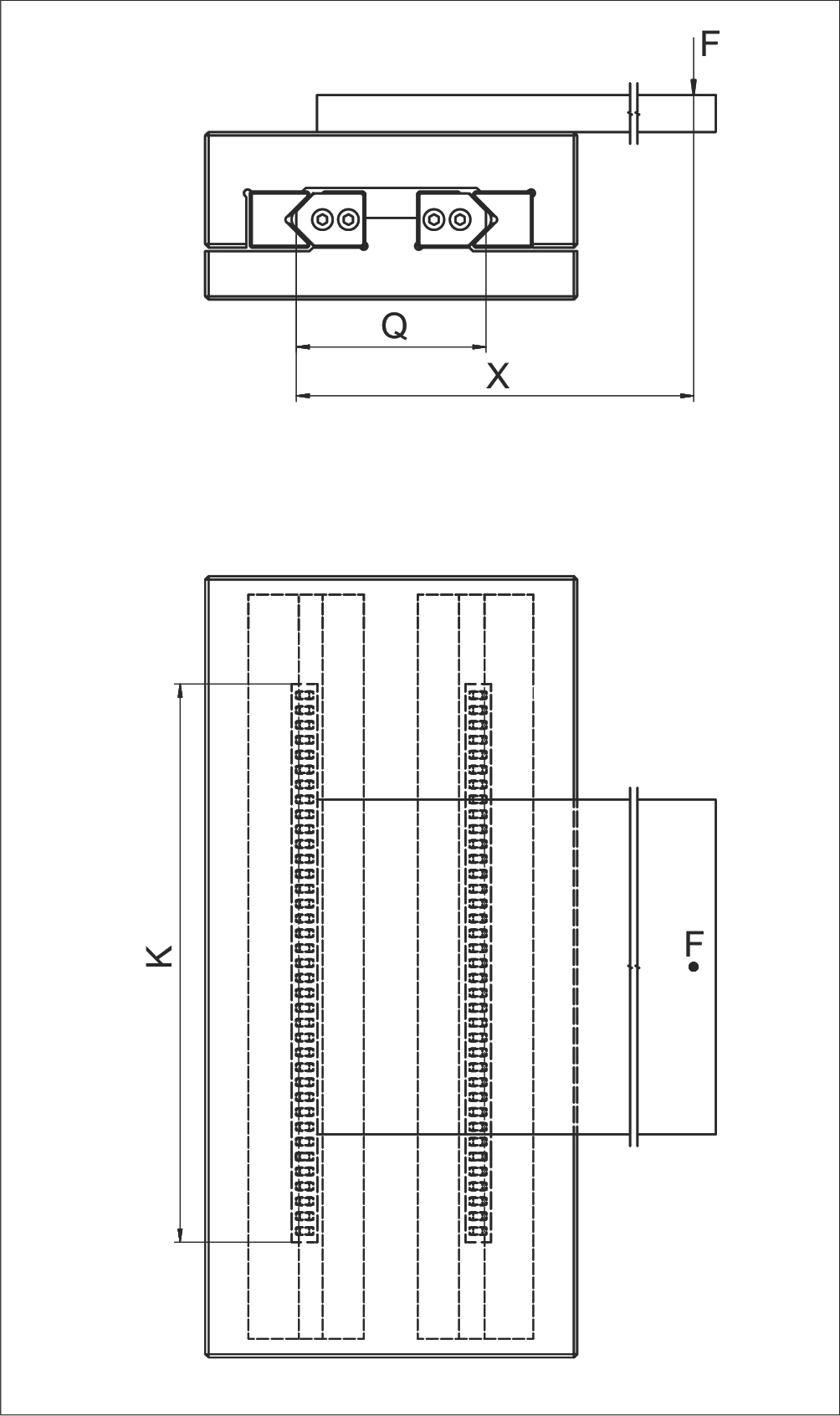

Example 4: Equivalent Load P for RNG Guideways

Assumptions:

- RNG type linear guideway

- KBN cage with 10 rollers (RA = 10)

- Load F = 15,000 N

- Lever arm distance X = 50 mm

- Linear guideway center distance Q = 100 mm

Calculation Steps:

Step 1: Calculate number of load-bearing rollers RT

Step 2: Calculate equivalent load P₁ from eccentric load

Step 3: Calculate equivalent load P₂ from vertical load

Step 4: Calculate total equivalent load P

Step 5: Select appropriate KBN cage size

- KBN 4: C = 850 N < 3,000 N ✗

- KBN 6: C = 1,800 N < 3,000 N ✗

- KBN 9: C = 3,900 N > 3,000 N ✓

✓ Select KBN 9 cage, C = 3,900 N > P = 3,000 N. Safety factor = 3,900 / 3,000 ≈ 1.30

KBN Cage Dimensions and Load Capacity

| Type | Size | Roller Diameter Dw (mm) | Division t (mm) | Width w (mm) | Load Capacity C per Roller (N) |

|---|---|---|---|---|---|

| KBN | 4 | 4.5 | 6.5 | approx. 4 | 850 |

| 6 | 6.5 | 8.5 | approx. 5 | 1,800 | |

| 9 | 9 | 12 | approx. 7.5 | 3,900 | |

| 12 | 12 | 15 | approx. 9 | 6,500 |

Example 5: Equivalent Load P per Needle

Assumptions:

- Linear guideway type N/O 2025

- SHW 15 cage with length K = 194 mm

- Cage end width w = 2.9 mm

- Needle division t = 4 mm

- Load F = 5,000 N

- Lever arm distance X = 280 mm

- Guideway center distance Q = 75 mm

- C = 750 N (max. permissible load capacity per needle)

Calculation Steps:

Step 1: Calculate total number of needles RA

Step 2: Calculate number of load-bearing needles Rt

Step 3: Calculate equivalent load P per needle

✓ P (388.3 N) is less than C (750 N), therefore this design is correct. Safety factor = 750 / 388.3 ≈ 1.93

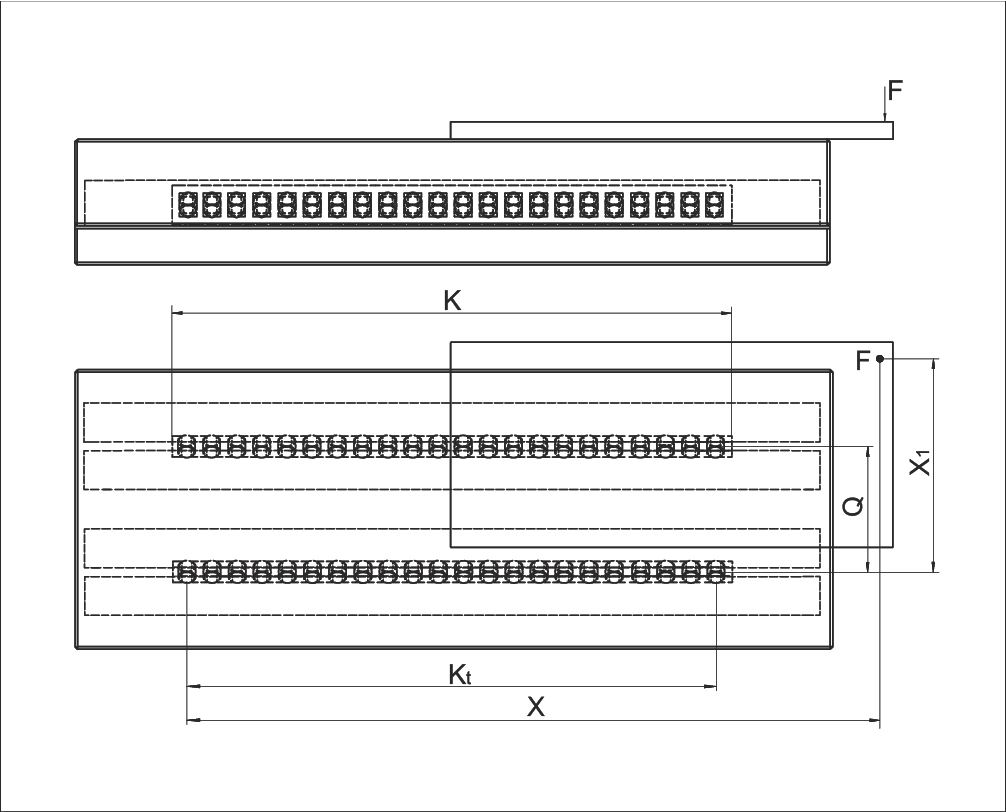

Example 6: Equivalent Load P per Roller (Longitudinal and Lateral)

Assumptions:

- Rigid structure

- Linear guides type R 12

- Cage type AC 12, length K = 400 mm

- F = 2,000 N

- X = 500 mm

- X1 = 200 mm

- Q = 100 mm

- C = 2,500 N (see chapter 5.1 AC 12 cage technical specifications)

For the roller cage AC 12 the following applies:

Calculate load-bearing length Kt

Calculate total number of rollers RA

Calculate number of load-bearing rollers Rt

Calculation for P per roller:

Load laterally

Load longitudinally

Total equivalent load

✓ P is smaller than C. The design is correct.

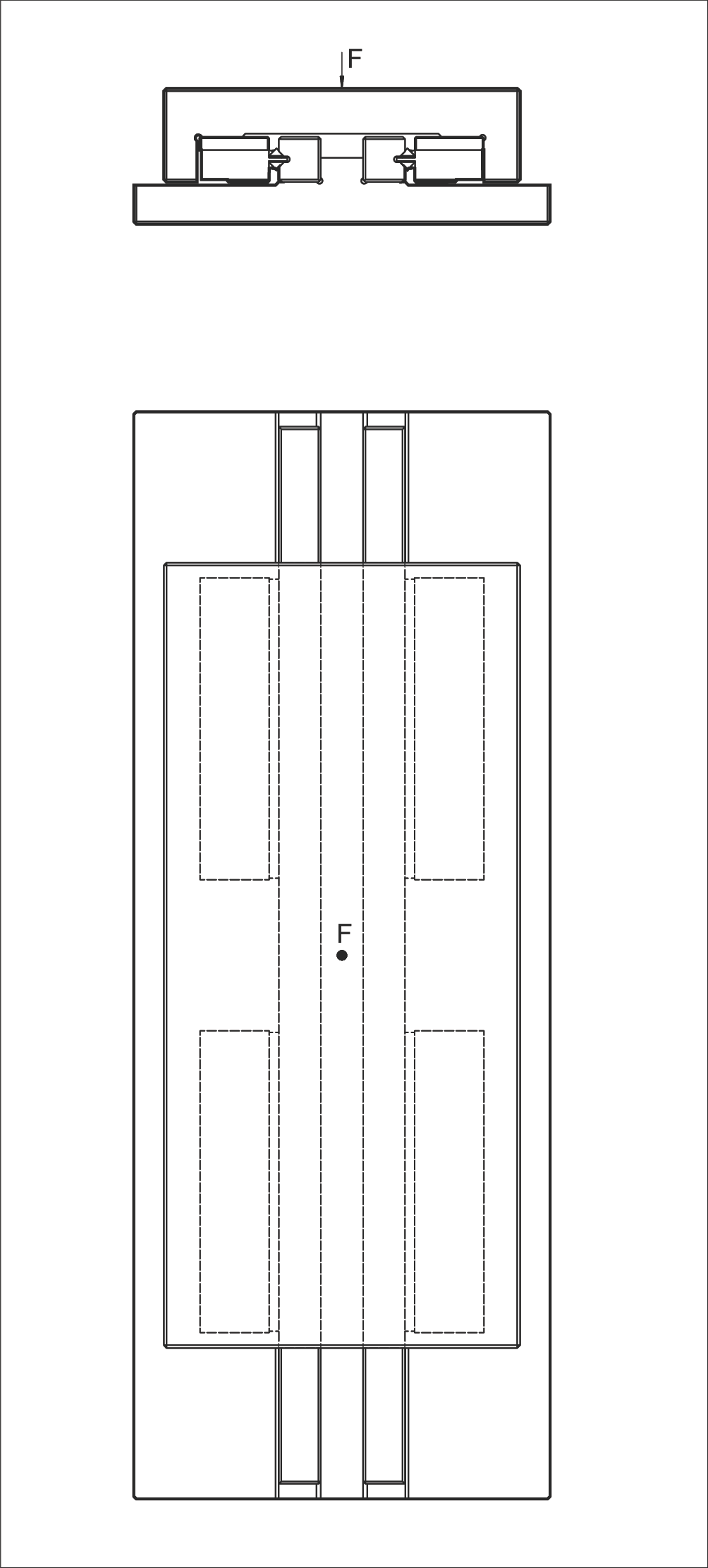

Example 7: Equivalent Load P for Recirculating Unit

Assumptions:

- Recirculating unit type SR 6-100

- Linear guideway type R 6

- Number of recirculating units Rt = 2 (dual configuration)

- Load F = 6,000 N

- C = 2,150 N (max. permissible load capacity per recirculating unit)

Calculation Steps:

Step 1: Calculate single-side load

Step 2: Calculate equivalent load P per recirculating unit

✓ P (1,500 N) is less than C (2,150 N), therefore this design is correct. Safety factor = 2,150 / 1,500 ≈ 1.43

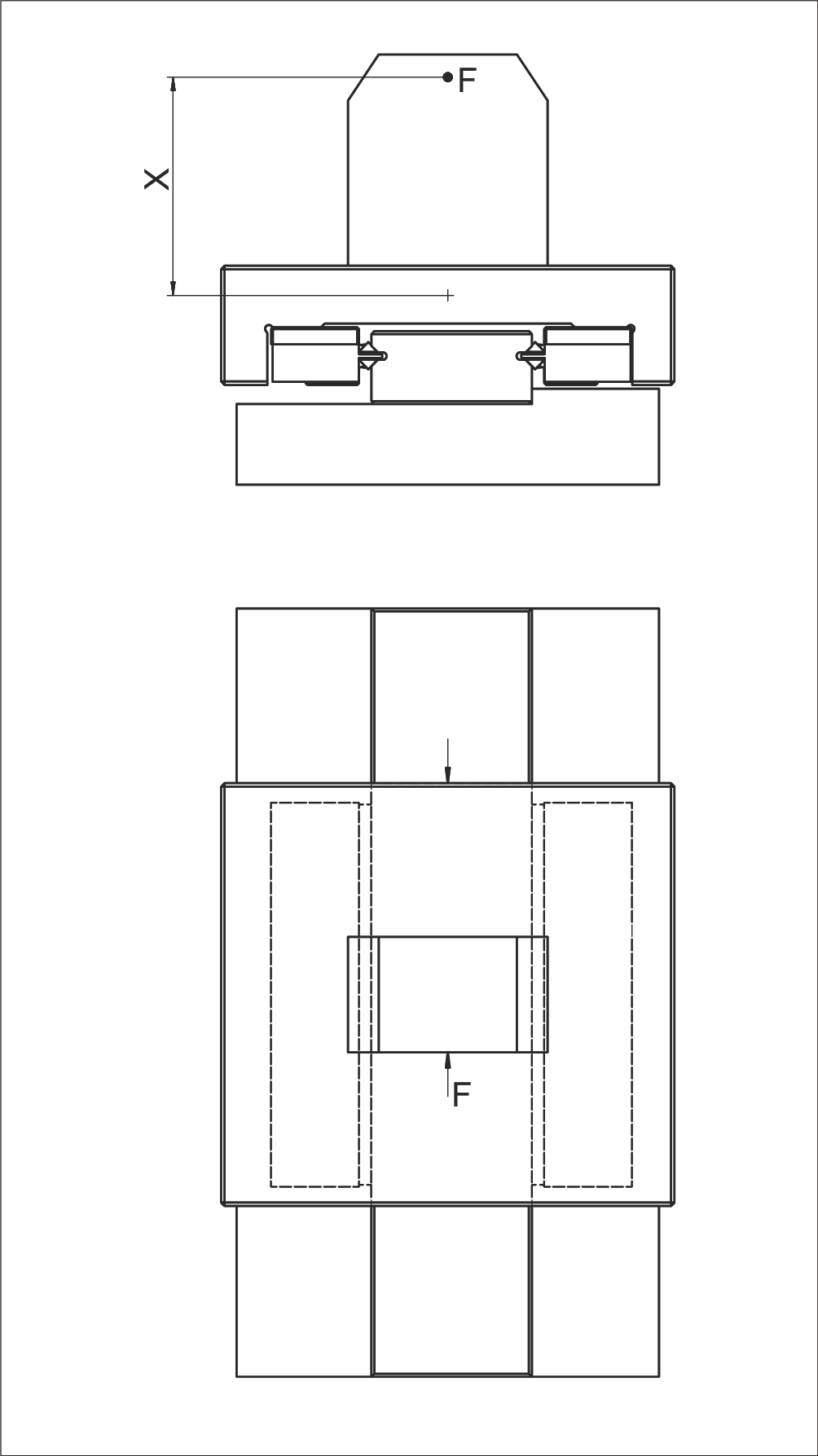

Example 8: Moment Load M Longitudinally and Laterally

Assumptions:

- Recirculating unit type SR 6-150

- Linear guideway type RD 6

- Load F = 2,000 N

- Lever arm distance X = 45 mm

- ML = 112 Nm (permissible moment load longitudinally and laterally)

Calculation Steps:

Step 1: Convert lever arm distance to meters

Step 2: Calculate actual moment load M

Step 3: Verify moment load is within permissible range

- Actual moment load: M = 90 Nm

- Permissible moment load: ML = 112 Nm

- M < ML ✓

✓ Moment load M (90 Nm) is less than permissible load ML (112 Nm), therefore this design is correct. Safety factor = 112 / 90 ≈ 1.24

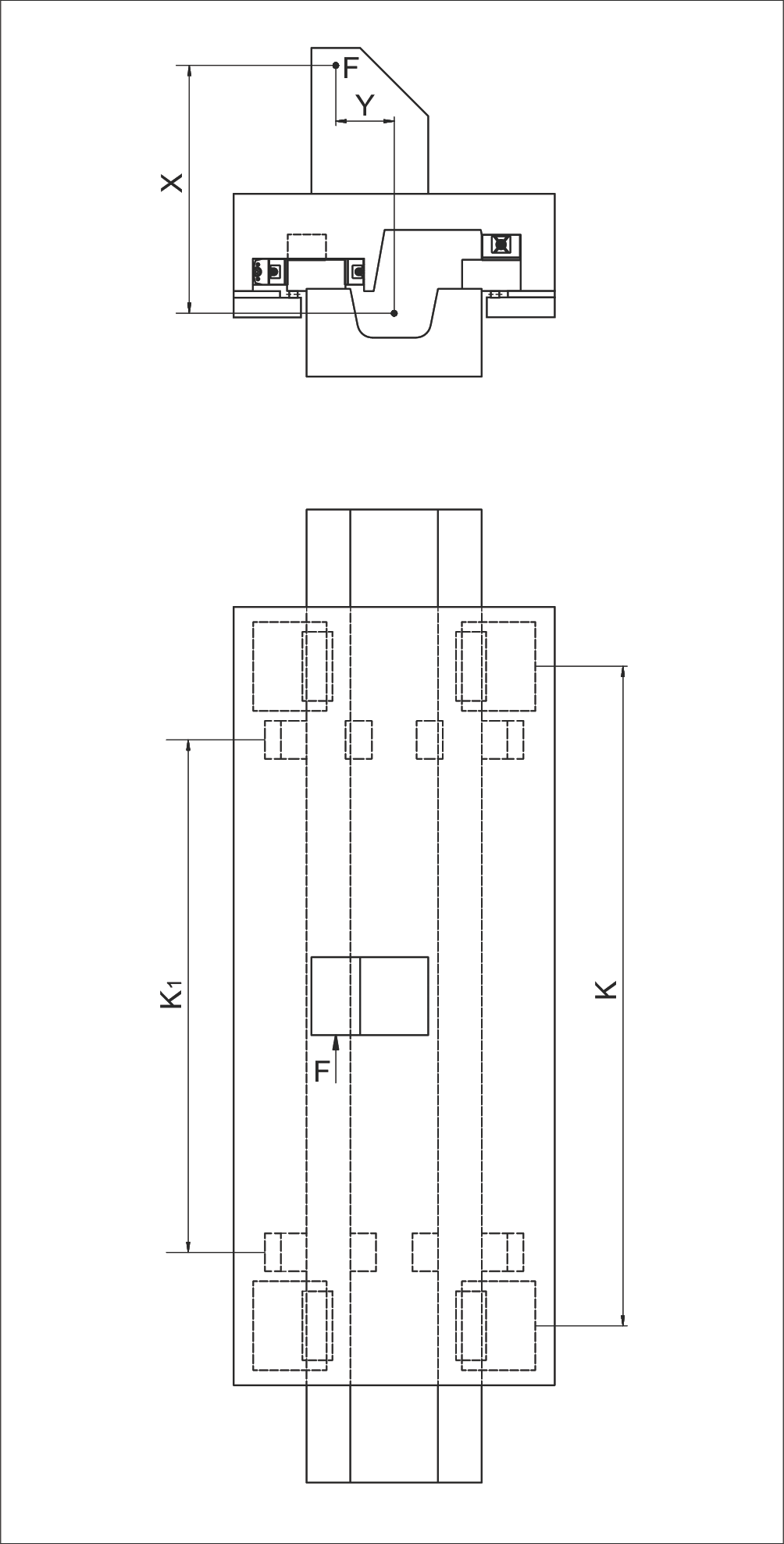

Example 9: Equivalent Loads PL and PQ

Assumptions:

- Recirculating unit type NRT 26 111 (top)

- Recirculating unit type NRT 19 077 (bottom and side)

- C = 98,000 N (top recirculating unit)

- C = 43,000 N (bottom and side recirculating units)

- K = 700 mm

- Kt = 450 mm

- Rtmin = 0.5

- F = 83,000 N

- X = 500 mm

- Y = 100 mm

Calculation Steps:

Load longitudinally

Load laterally