The Finished Product, Right on the Assembly Line

Schneeberger Mineralgusstechnik provides our customers with a finished, ready-to-use product for final assembly. Depending on the customer's wishes, this can be supplied with:

- Precision surfaces

- Threaded inserts and other cast-in components

- Reference surfaces

- Coated surfaces

SCHNEEBERGER Mineral Casting Production Process

Giving Our Customers a Competitive Advantage

Because we can bring several small stages together in the process, our customers benefit from very short processing times – which in turn gives them decisive savings in both the time and cost of their production processes.

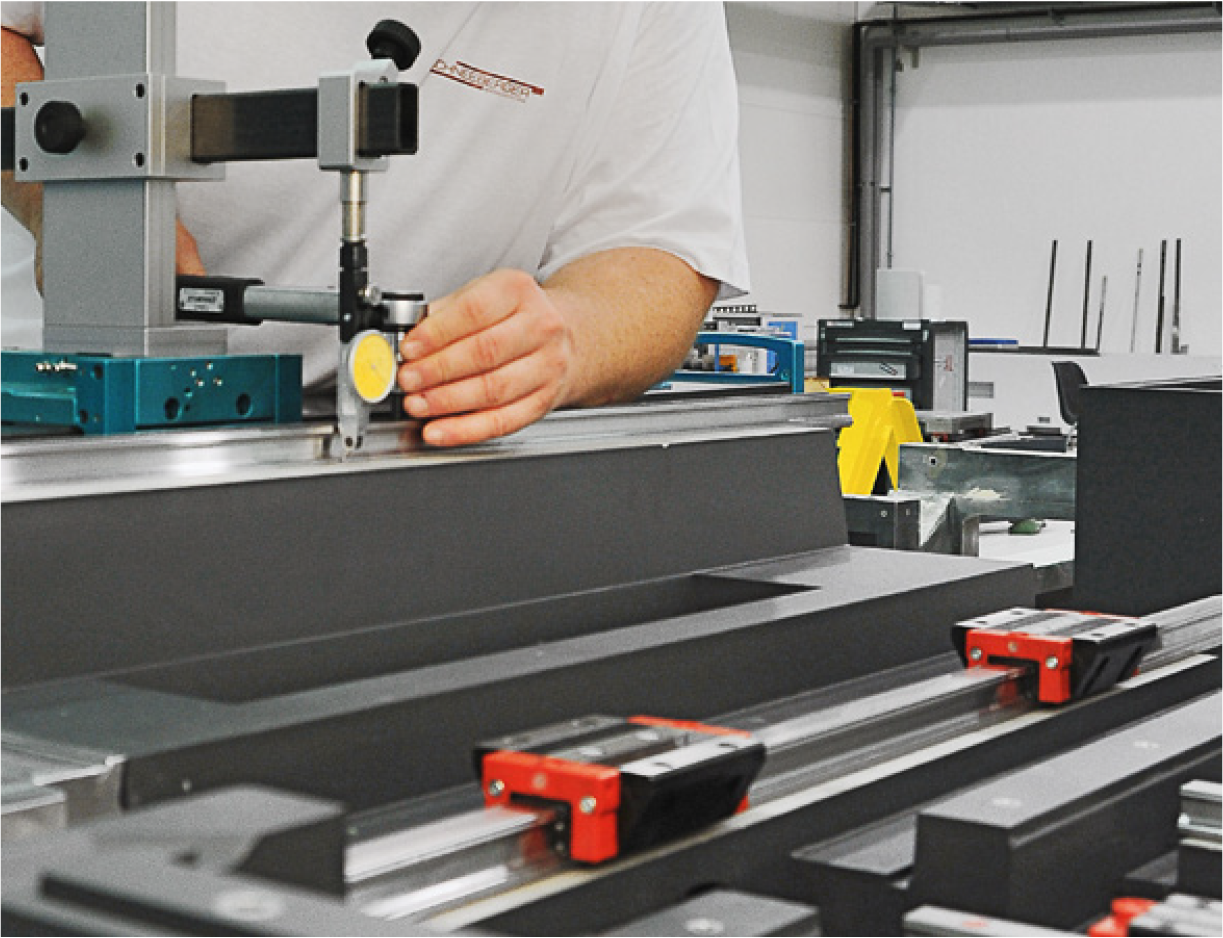

We use the latest technology to produce challenging high-accuracy surfaces, along with the relevant tools and templates.

Parts produced in mineral casting are subject to very strict quality assurance measures. This means that our customers can be sure that even complex machine structures and sub-assemblies are produced to the specified dimensions and to the highest quality. We use the very latest measuring instruments to check our high-precision work, and we record the results in our comprehensive measurement reports.

The consistent high quality of our products is demonstrated by the fact that time and again, the reliability and quality of our customers' equipment is recognised by their own customers.

A One-Stop Solution

Combining linear technology with mineral casting offers unbeatable customer benefits.

Schneeberger is a leading global manufacturer of mineral castings. As well as innovative and high-precision mineral casting solutions, Schneeberger also offers fully-assembled bases and systems. Depending on the customer's requirements, these can be equipped with the following components:

- Linear bearings

- Linear motors

- Electronics and sensor technology

- Drive units

Because we offer a one-stop solution, we can guarantee that the various different components will work well together.

Delivery Contents

Basic Configuration

- Precision surfaces

- Threaded inserts

- Cast-in components

- Reference surfaces

System Integration

- Linear bearings

- Linear motors

- Sensor technology

- Drive units

Quality Assurance

- Strict QA measures

- Predictable high quality

- Complex structure production

- Customer recognition