Positioning Hole

To correctly align the bearing lubrication hole with the machine housing lubrication hole, AXRY-NGX bearings feature a locating pin hole (1) on the outer ring.

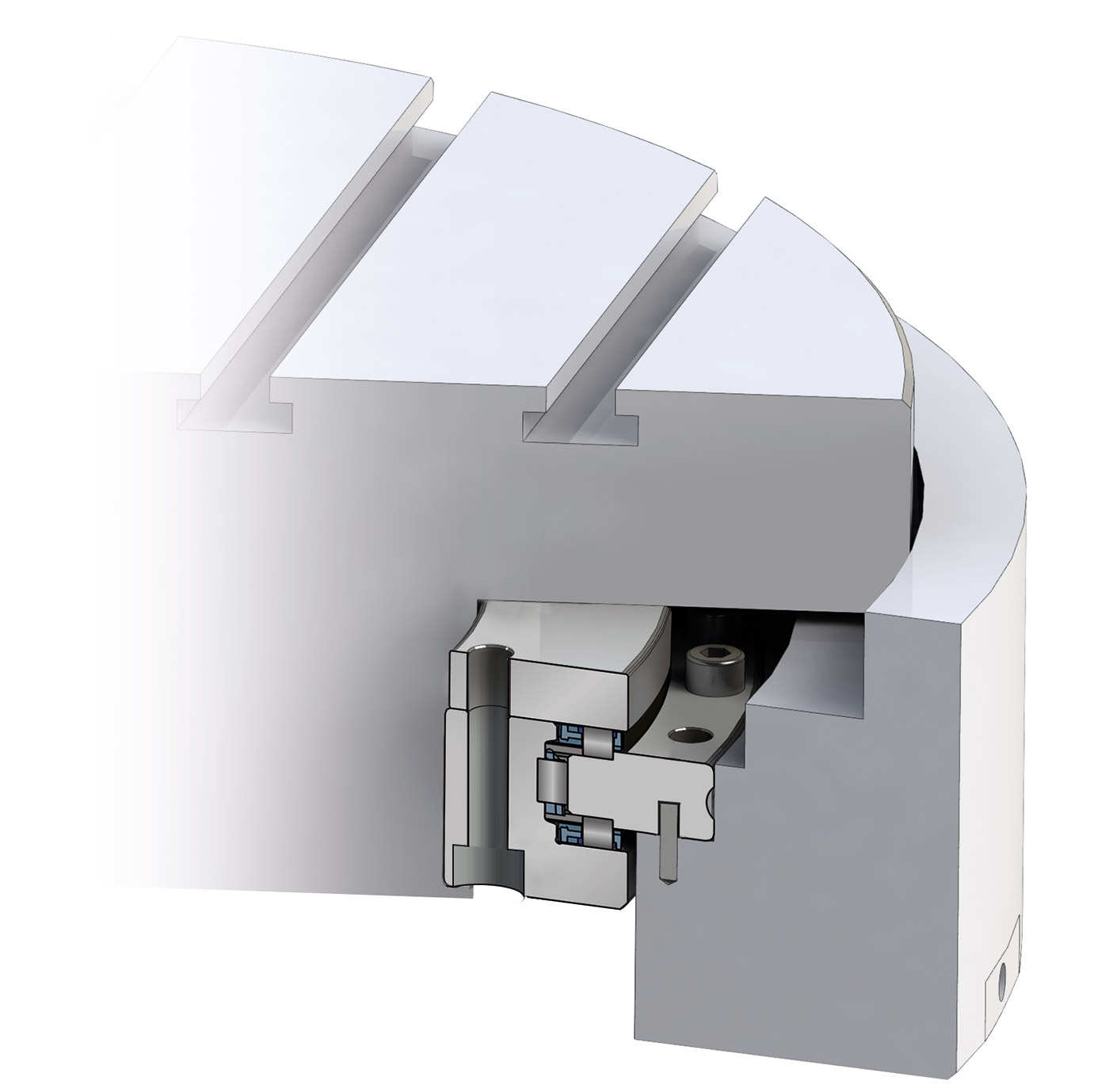

The diagram below shows the fastening screws (4) and the bearing mark on the inner ring above. The axial washer is mounted on the table.

Figure: Locating pin hole design schematic

Figure: AXRY-NGX bearing positioning hole location

Hole Position Relationship

- Positioning hole (1) is offset by half a pitch division to the fixing hole (3)

- Positioning hole (1) is offset by one whole pitch division to the lubrication hole (2)

- The pitch for each bearing is listed in the "Fixing Holes" table in the product data sheet

The positioning hole diameter dPB on the bearing outer ring is designed to be slightly larger than the recommended pin diameter dST (see table below).

AXRY-NGX Positioning Hole Design

Important Reminder

Secure the positioning pins appropriately during assembly. The pins must be reliably prevented from dropping out in operation.

| Bearing Model | Pin Height hmax [mm] | Pin Diameter dST [mm] | Positioning Hole Diameter dPB min. [mm] |

|---|---|---|---|

| AXRY 180-460-NGX | 4 | 4 | 5 |

| AXRY 580-NGX | 6 | 6 | 8 |

| AXRY 650-NGX | 8 | 8 | 10 |

Symbol Description:

hmax = Maximum pin height

dST = Recommended pin diameter

dPB min. = Minimum positioning hole diameter

Lubrication Hole Configuration

NGX (Inner Ring Rotates)

NGX bearings for rotating inner ring can be lubricated either through the radial annular groove on the outer ring or axially.

Radial Lubrication

- Through outer ring annular groove

- Housing lubrication channel should be close to bearing radial lubrication hole

- Suitable for connection to machine tool central lubrication system

Axial Lubrication

- Through outer ring end face

- Axial holes are closed with plugs upon delivery

- Remove plugs when using axial lubrication

Note

Upon delivery, the axial lubrication holes are closed with plugs. For axial lubrication, remove the plugs axially and close radially.

NGX-SBI (Outer Ring Rotates)

NGX-SBI bearings for rotating outer ring are lubricated through the radial annular groove on the inner ring.

NGX-SBI Lubrication Features

- Only radial lubrication supported (through inner ring)

- Bearing lubrication hole should be close to housing lubrication channel

- Suitable for applications with stationary shaft and rotating outer ring

Lubrication Groove Filling Recommendation

For relubrication through the outer/inner ring lubrication groove, it is recommended to completely fill the lubrication groove with grease before installing the bearing.

Advantages

- Grease can enter the bearing faster during relubrication

- Reduced friction during initial operation

- Ensures lubrication channel is clear

Filling Guidelines

- Use the same type of grease as the bearing

- Ensure the lubrication groove is clean and free of foreign matter

- Fill the entire annular groove evenly

- Avoid overfilling which may cause installation difficulties

Relubrication Recommendations

| Item | Recommendation |

|---|---|

| Relubrication Interval | Typically once per year |

| After Relubrication | Perform a running-in cycle |

| Lubricant Quantity | Contact myonic application engineering team |

| Grease Type | Standard: DIN 51825-KPH-C1N-30 |

Over-Lubrication Warning

Over-lubrication directly leads to increased bearing friction and significant temperature rise, which may cause premature bearing failure. If the bearing is over-lubricated, repeat the running-in cycle to restore the original friction torque.