4.5.1 Definition and Purpose

SCHNEEBERGER MONORAIL guideways are preloaded to achieve zero backlash movement under load and to increase the rigidity of the guideway system. At the same time, preload also affects the service life, displacement resistance and vibration characteristics of the system.

Preload is generated by using oversized rolling elements in the carriage, which causes elastic bending of the steel body of the carriage. The resulting restoring force is the preload force.

Preload is expressed as a percentage of the dynamic load capacity C.

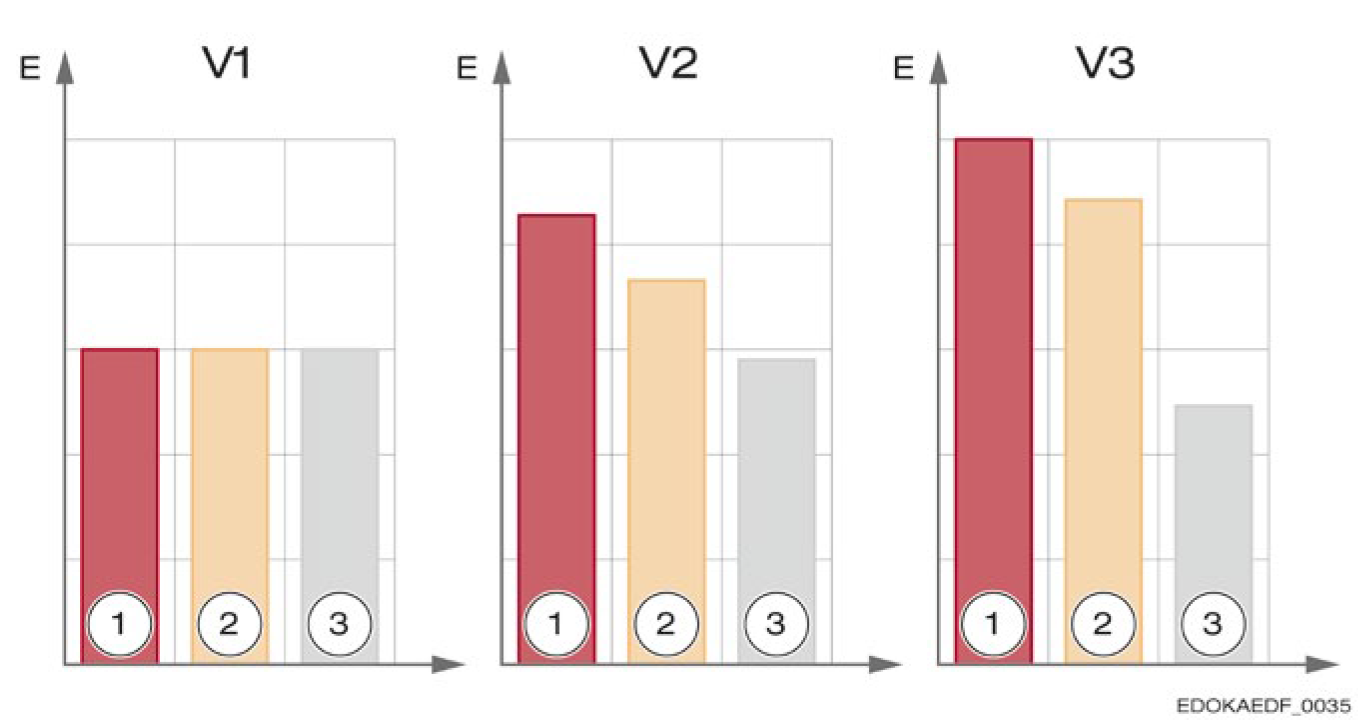

Influence of each preload class on the following characteristics E: Rigidity, displacement resistance, service life

Influence of Rigidity on Guideway Vibration Characteristics

The amplitude of low-damping systems depends on the ratio of excitation frequency to natural frequency. Higher rigidity increases the natural frequency and reduces static deflection. In machine tools, the goal is to obtain a high natural frequency so that the amplified amplitude can be kept as small as possible at the specified excitation force and excitation frequency.

Conclusion: Use roller guideways with high preload class.

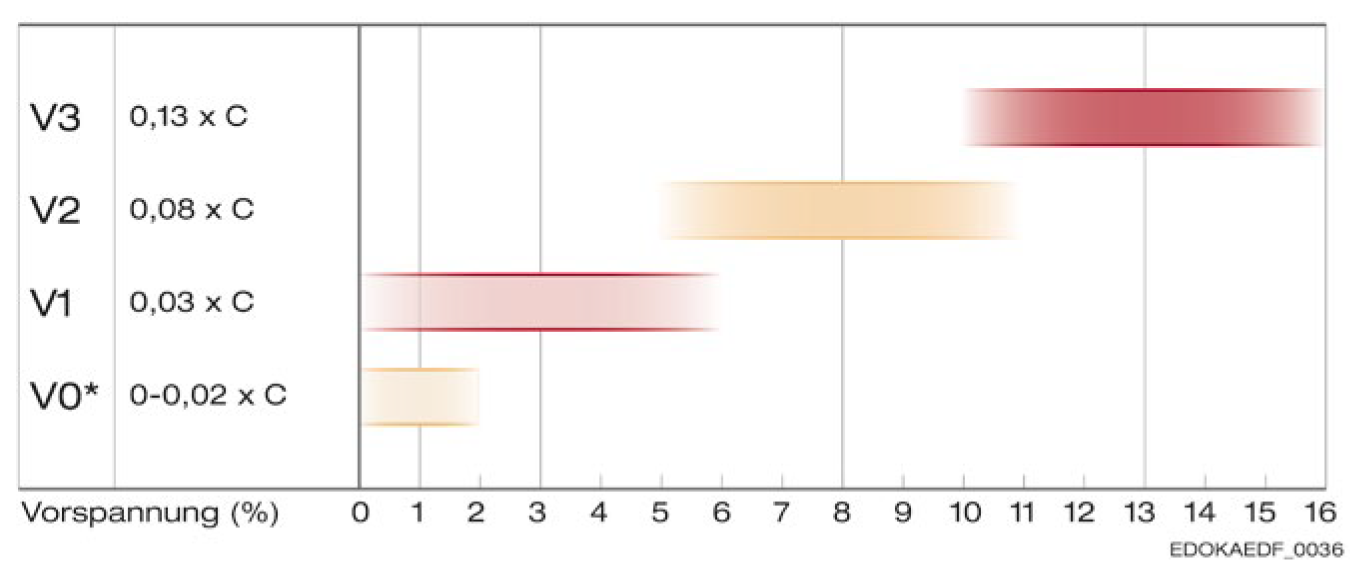

4.5.2 Preload Classes

SCHNEEBERGER offers four different preload classes for different requirements, ranging from 0 to 13% of the dynamic load capacity C. The tolerance of the preload class is ± 3% of C. The values in the following diagram can be found in the SCHNEEBERGER MONORAIL and AMS product catalog.

Preload Classes

Note: * V0 only applies to BM guideways.

4.5.3 Areas of Application

SCHNEEBERGER MONORAIL MR roller series guideways offer three preload classes: V1, V2 and V3, representing low, medium and high preload respectively.

MONORAIL BM ball guideways also offer preload class V0. The preload of this class can vary between extremely low preload and low backlash. The following table lists typical application areas:

Preload Class: V0

Operating Conditions:

- Ultra-low friction guideways with uniform loads

- Minimum vibration

Application Examples:

- Manual axes

- Small axes and table systems for: Electronics/Cleanroom/Medical technology

- Auxiliary axes

- Linear motor axes

Preload Class: V1

Operating Conditions:

- Low friction guideways with uniform loads

- Minimum vibration

Application Examples:

- Handling axes

- Robotics

- Measuring systems

- Laboratory equipment

- Auxiliary and secondary axes

Preload Class: V2

Operating Conditions:

- High rigidity

- Medium alternating loads and vibrations

Application Examples:

- Machine tools with light cutting forces

- Grinding machines

- Woodworking machinery

- Water jet systems

- Laser cutting systems

- EDM machines

Preload Class: V3

Operating Conditions:

- Maximum rigidity

- High impact loads and vibrations

- High loads and moments with significant variations

Application Examples:

- Machine tools with high cutting forces

- Presses

- Milling centers

- Lathes

- Drilling machines

Effectiveness of Preload

When the external load is less than 3 times the preload force, the system remains preloaded under load. This means the system has high rigidity. If the external force exceeds the preload value, the rigidity will decrease. Therefore, it is very important in design to ensure staying within the effective preload force range if higher rigidity is required.