16 Installation and Adjustment Guidelines

MINIRAIL and MINISCALE PLUS

16.1 Guide Rail Alignment Methods

The alignment of the guide rail depends on the required level of accuracy and must be specified during the machine construction phase, as this is when the number of reference surfaces and their positions are determined. Alignment methods are divided into the following types:

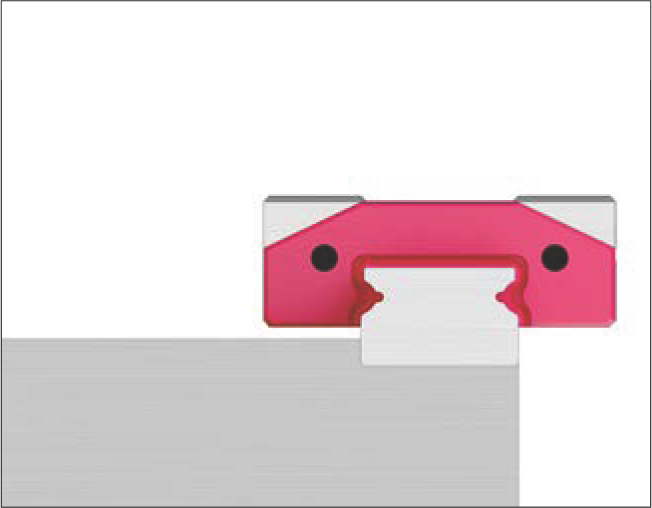

No Reference Edge Available

- Manual alignment without tools

- Not recommended

- Very low accuracy and poor lateral force absorption

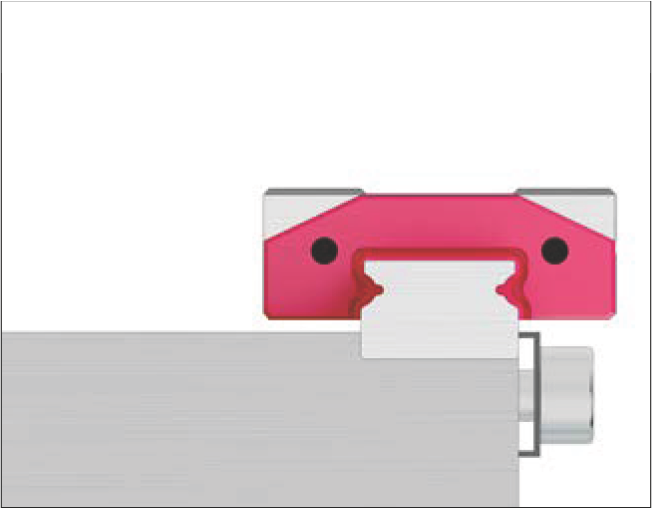

No Reference Edge Available

- Manual alignment using tools, e.g. alignment rulers, guide bars, dial indicators, installation carriages

- Medium to high accuracy depending on complexity

- Lower accuracy and lateral force absorption

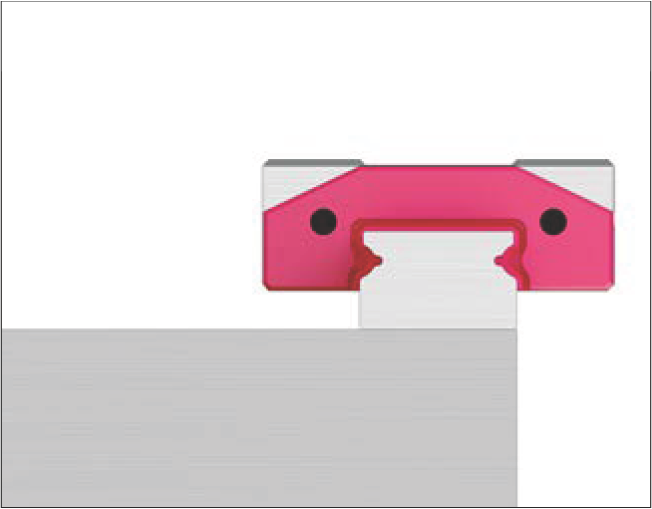

Lateral Reference

- Alignment by pressing against reference surface

- High accuracy, depending on precision of reference edge

- Very fast installation due to predefined reference edge

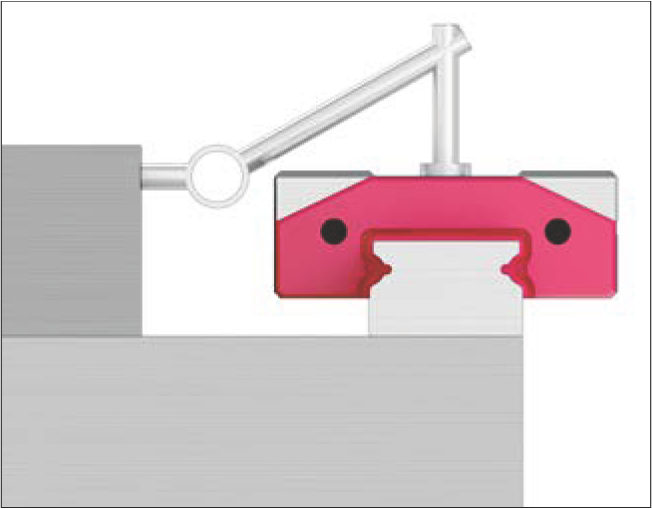

Lateral Reference Surface and Additional Lateral Clamping

- Alignment by pressing against reference surface assisted by lateral clamping elements

- Very high accuracy, depending on precision of reference edge

- Very fast installation due to predefined reference edge