Guide rail types mainly differ in their mounting method, which also determines the closure options for fixing holes. In addition, there are different fixing hole spacings and hardness characteristics. This chapter provides an overview of MONORAIL MR roller and MONORAIL BM/BZ ball types, as well as detailed criteria for guide rail selection.

4.3.1 Guide Rail Types Overview

Guide rail types mainly differ in their mounting method, which also determines the closure options for fixing holes. In addition, there are different fixing hole spacings and hardness characteristics. The following table provides an overview of MONORAIL MR roller and MONORAIL BM/BZ ball types. For available sizes, please refer to the SCHNEEBERGER MONORAIL and AMS product catalog.

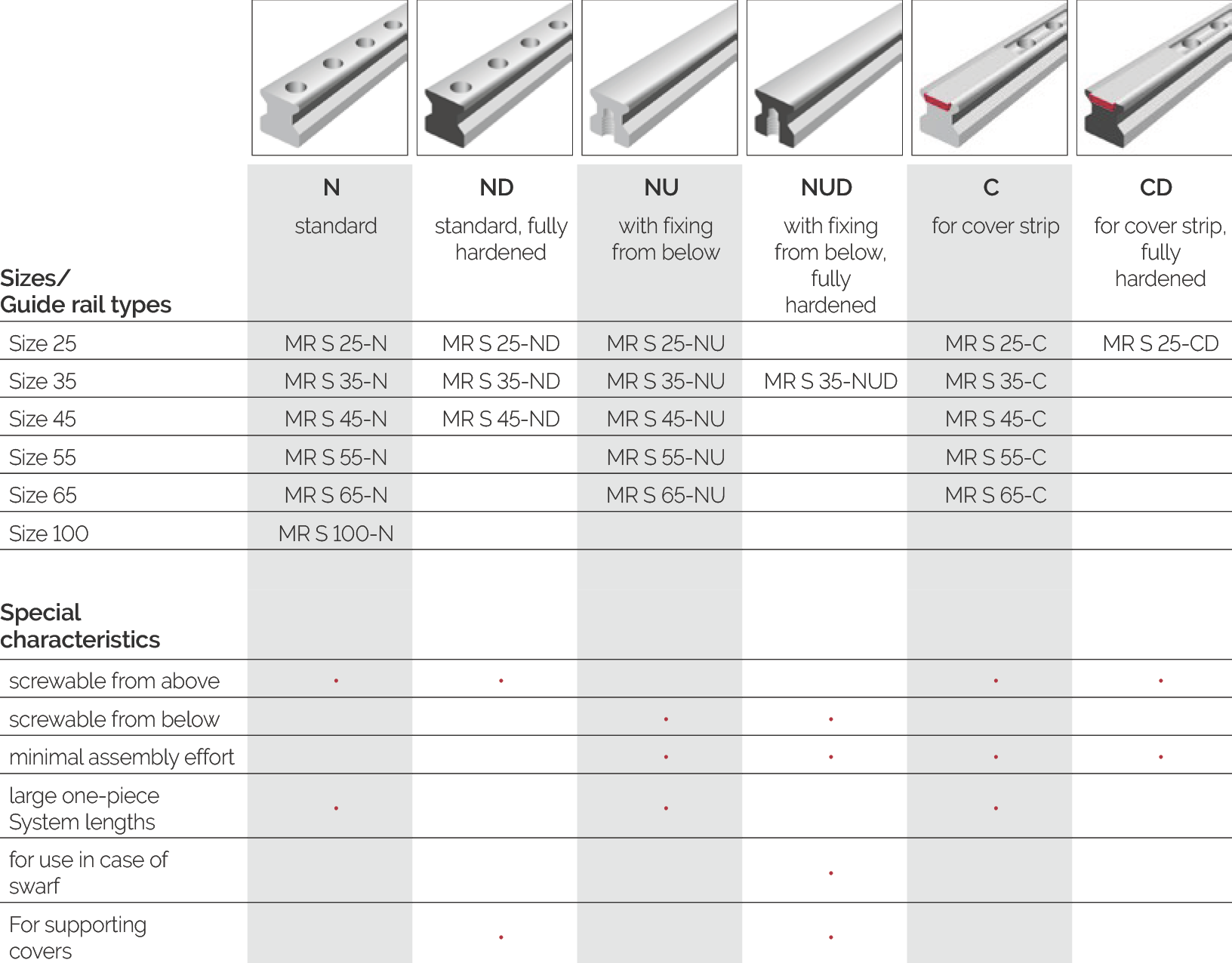

MR Guide Rail Product Overview

| Size / Guide Rail Type | ||||||

|---|---|---|---|---|---|---|

| N Standard | ND Standard Fully hardened | NU Bottom mounting | NUD Bottom mounting Fully hardened | C Cover strip | CD Cover strip Fully hardened | |

| Size 25 | MR S 25-N | MR S 25-ND | MR S 25-NU | MR S 25-C | MR S 25-CD | |

| Size 35 | MR S 35-N | MR S 35-ND | MR S 35-NU | MR S 35-NUD | MR S 35-C | |

| Size 45 | MR S 45-N | MR S 45-ND | MR S 45-NU | MR S 45-C | ||

| Size 55 | MR S 55-N | MR S 55-NU | MR S 55-C | |||

| Size 65 | MR S 65-N | MR S 65-NU | MR S 65-C | |||

| Size 100 | MR S 100-N | |||||

| Special Characteristics | ||||||

| Fixing from above | ● | ● | ● | ● | ||

| Fixing from below | ● | ● | ||||

| Minimum assembly work | ● | ● | ● | ● | ||

| Large monolithic system length | ● | ● | ● | |||

| For chip environment | ● | |||||

| For supporting cover strips | ● | ● | ||||

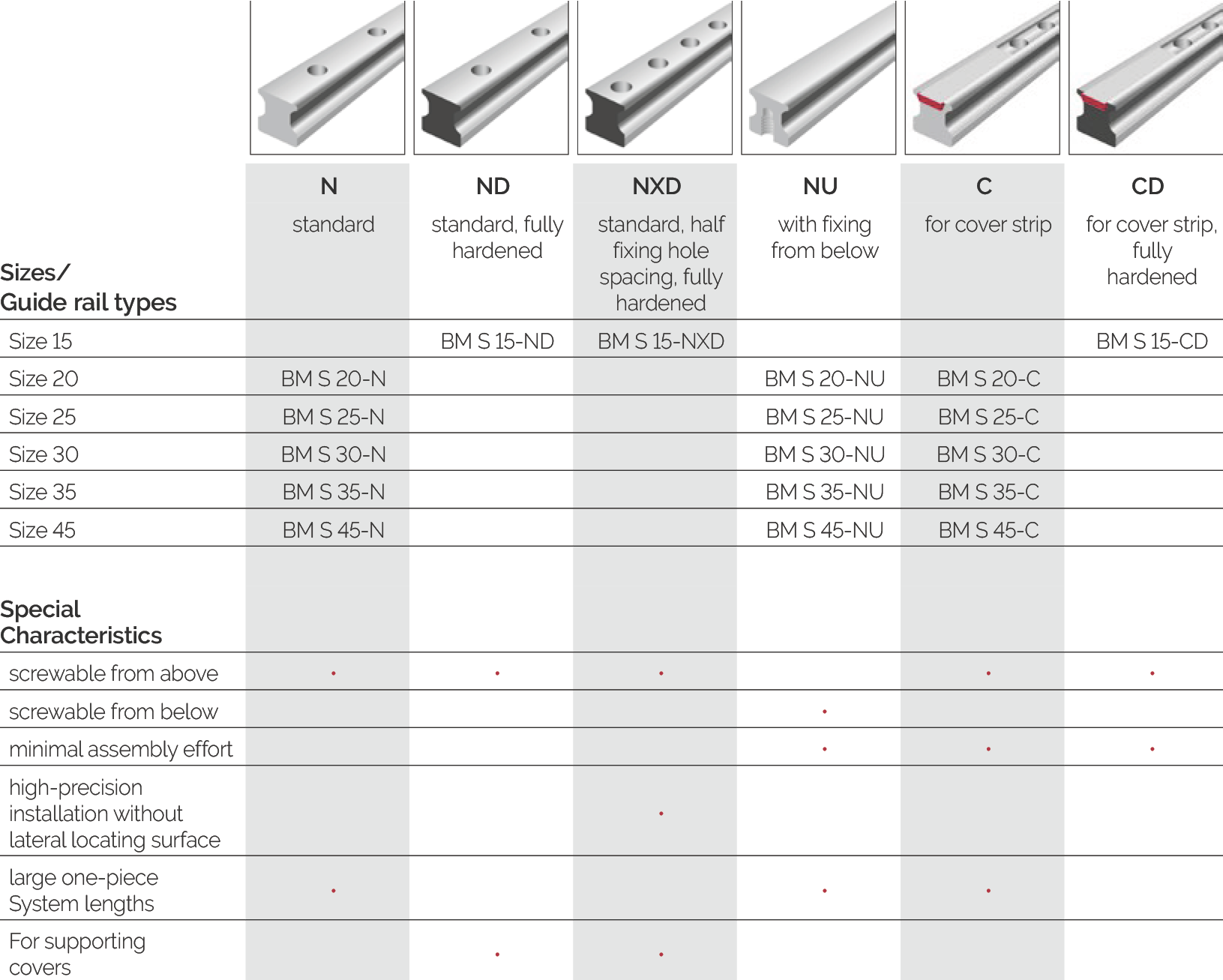

BM Guide Rail Product Overview

| Size / Guide Rail Type | ||||||

|---|---|---|---|---|---|---|

| N Standard | ND Standard Fully hardened | NXD Standard Half hole spacing Fully hardened | NU Bottom mounting | C Cover strip | CD Cover strip Fully hardened | |

| Size 15 | BM S 15-ND | BM S 15-NXD | BM S 15-CD | |||

| Size 20 | BM S 20-N | BM S 20-NU | BM S 20-C | |||

| Size 25 | BM S 25-N | BM S 25-NU | BM S 25-C | |||

| Size 30 | BM S 30-N | BM S 30-NU | BM S 30-C | |||

| Size 35 | BM S 35-N | BM S 35-NU | BM S 35-C | |||

| Size 45 | BM S 45-N | BM S 45-NU | BM S 45-C | |||

| Special Characteristics | ||||||

| Fixing from above | ● | ● | ● | ● | ● | |

| Fixing from below | ● | |||||

| Minimum assembly work | ● | ● | ● | |||

| High precision mounting without lateral datum surface | ● | |||||

| Large monolithic system length | ● | ● | ● | |||

| For supporting cover strips | ● | ● | ||||

Legend

- N: Standard guide rail

- D: Fully hardened/densified version

- U: With bottom mounting capability

- C: Cover strip version

- ●: This model has this characteristic

4.3.2 Guide Rail Selection Criteria

Mounting Method

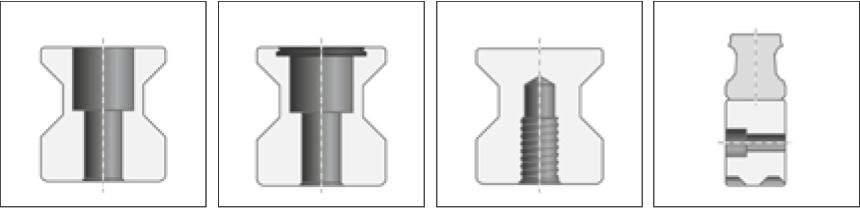

There are two main mounting methods for guide rails. Standard guide rails -N- and cover strip guide rails -C- have continuous fixing holes for mounting from above. N-type guide rail fixing holes can be closed with plastic plugs, brass plugs or steel plugs.

There are also guide rails with threaded fixing holes on the bottom for mounting from below. These guide rails are marked with the -NU- suffix.

The -D- suffix in the model description indicates fully hardened guide rails, -X- indicates rack guide rails for ball bearings (BZ).

| Standard Guide Rails | Special Guide Rails | |||

|---|---|---|---|---|

| Model/Mounting Method | N, ND | C, CD | NU, NUD | NX (BZ) |

| Fixing from above | ● | ● | ||

| Fixing from below | ● | |||

| Fixing from side | ● | |||

Note: ● = Applicable

Side mounting represents the fourth variant. This is used for the MONORAIL BZ rack system. In this case, the fixing holes are outside the carriage travel range, and the advantage is that the fixing holes are very easy to access and the bolts can be protected from contamination.

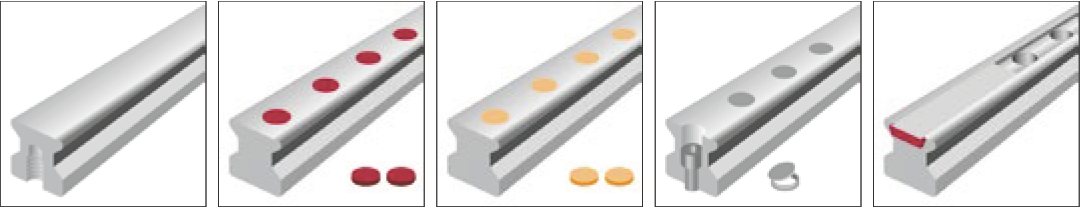

Guide Rail Covers

Depending on the guide rail type, the guide rail fixing holes can be closed in different ways. For this purpose, SCHNEEBERGER offers various elements for each specific application.

Selection Recommendation

When selecting guide rail covers, consider the application environment (liquids, dust, chips, etc.), cost budget, installation convenience and maintenance requirements. For detailed cover selection criteria, please refer to the product catalog or consult the SCHNEEBERGER technical team.