1.1.1 Linear Guideway Types

Linear guideways are used to enable precise linear motion in mechanical and technical systems. Depending on the type, they are capable of transmitting forces and moments transverse to the direction of motion from the carriage to the machine bed, without the system undergoing significant deflection.

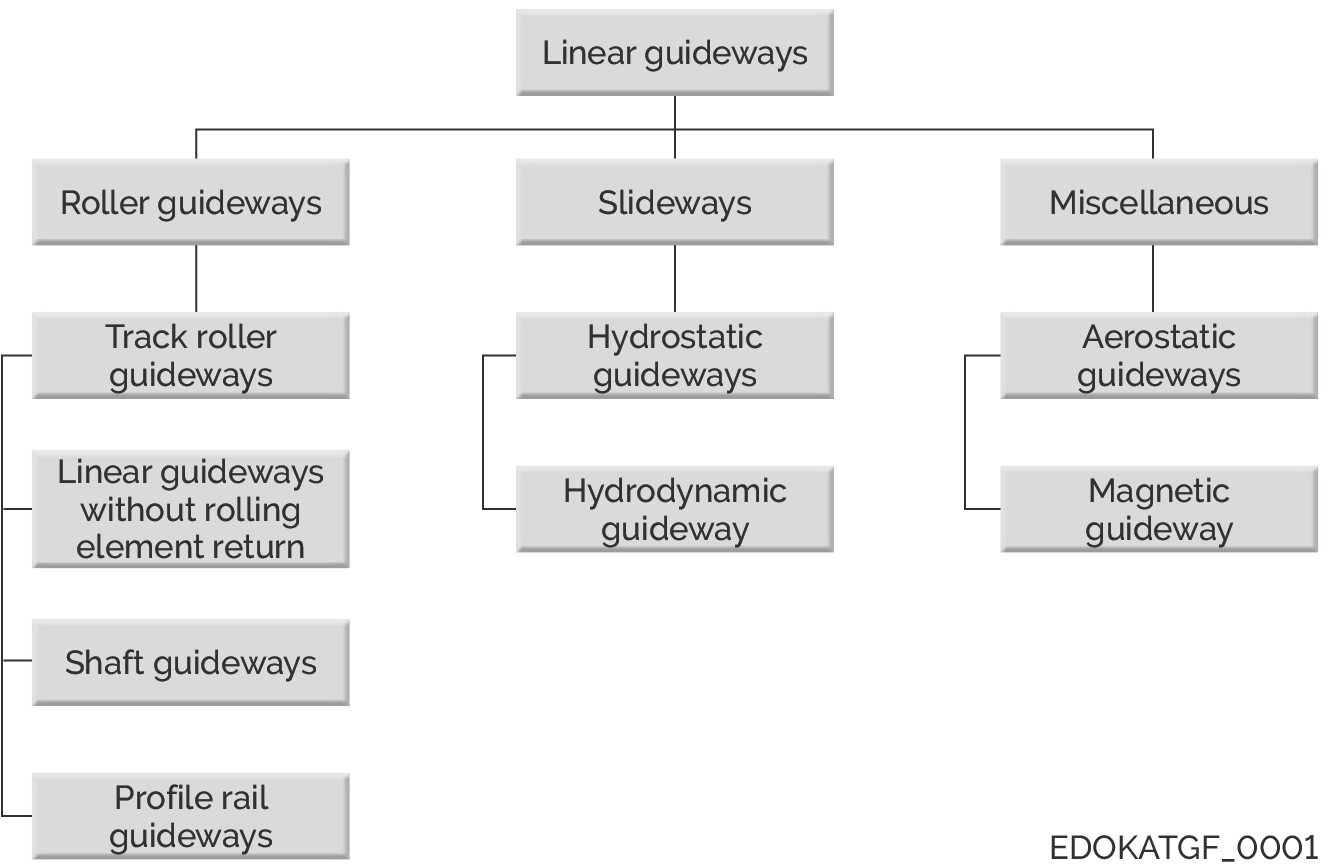

Figure 1.1 - Classification of linear guideways

Rolling element guideways can be further subdivided into those with and without recirculating units based on the manner in which the rolling elements move within the guideway.

For guideways without recirculating rolling element units, the stroke is limited by the length of the guiding element. Guideways with recirculating rolling element units (including SCHNEEBERGER profiled rail guideways) enable unlimited stroke.

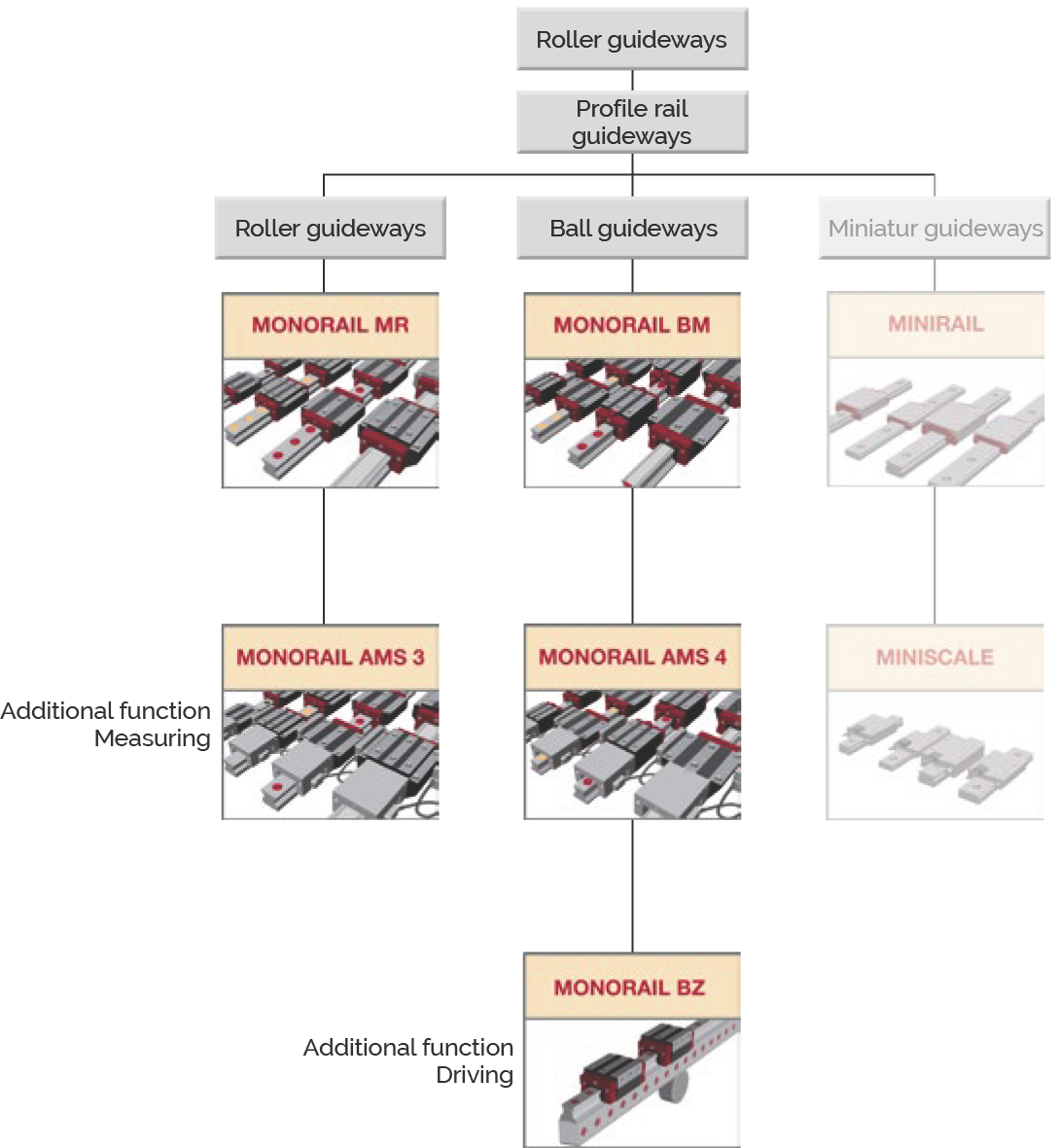

SCHNEEBERGER profiled rail guideways are compact, ready-to-install linear guideway systems, whose structure consists of profiled rail guideways and rolling element carriages with sealed recirculating units.

Figure 1.3 - SCHNEEBERGER profiled rail guideway product range

1.1.2 Characteristics and Advantages of SCHNEEBERGER MONORAIL Guideways

Due to increasing competition, products need to be manufactured at more cost-effective prices while achieving higher quality standards. This places strict demands on production equipment and its components, and SCHNEEBERGER MONORAIL guideways are highly capable of meeting these requirements.

Key Advantages

Load Capacity and Rigidity

Based on the design principle, despite the compact construction, SCHNEEBERGER MONORAIL guideways can withstand high load forces and moments from all directions. For this purpose, load capacity and rigidity must be considered separately.

Compared to ball guideways, roller guideways have higher load capacity and rigidity due to the larger contact area between the rolling elements and the raceways, thus enabling them to withstand higher load forces and moments.

Sustained Accuracy

When using SCHNEEBERGER MONORAIL guideways, the rolling elements roll on the raceways with virtually no sliding. Therefore, wear is extremely low, which is also due to the fully standardized materials and hardening methods used for all components.

Prerequisites for Maintaining Sustained Accuracy

- Adequate lubrication

- Appropriate measures to protect guideways from abrasive particle ingress

- Ensure no overloading

- Protection from chemical attack

Zero Backlash

SCHNEEBERGER MONORAIL guideways are preloaded to ensure that the profiled rail guideways do not exhibit backlash even under load. This means the rolling elements do not lift off from the raceways, ensuring precise and repeatable positioning.

Dynamic Characteristics

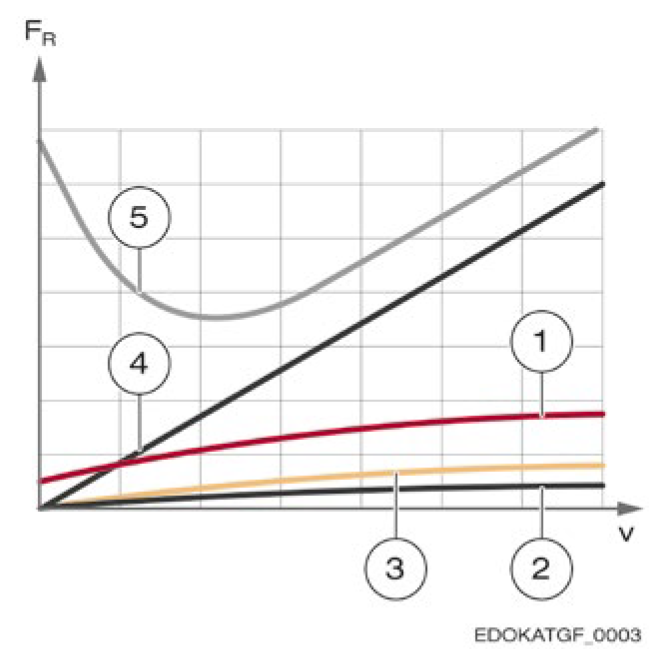

Modern SCHNEEBERGER MONORAIL guideways are very well suited for high-dynamic applications, clearly outperforming slide guideways in this regard. In principle, compared to sliding friction, rolling friction enables higher speeds and accelerations.

Smooth Motion

Apart from seal friction, SCHNEEBERGER MONORAIL guideways need to overcome the rolling friction of the rolling elements. Compared to slide guideways, they require significantly lower starting force.

Figure 1.4 - Friction force comparison for different guideway types

Velocity v versus friction force FR:

FR = friction force, v = velocity

Cost Effectiveness

SCHNEEBERGER MONORAIL guideways are standard machine elements whose structural forms, main dimensions, and specifications have been standardized. This guarantees interchangeability of systems from different manufacturers and ensures availability of standardized components.

Since the guideways are bolted to the machine bed as complete units, installation and adjustment costs are minimal. Compared to slide guideways, machine bed configurations are also simpler, thereby reducing manufacturing costs.

Integrating additional functions into the guideways provides another potential area for improving cost effectiveness, such as the BZ integrated rack drive or AMS integrated measuring system offered in SCHNEEBERGER products.

Environmental Sustainability

SCHNEEBERGER MONORAIL guideway carriages are fully sealed with wipers, and the recirculating units have cavities that serve as lubricant reservoirs. Therefore, lubricant consumption is minimal, contributing to environmental sustainability.