Guiding System Features and Options

Features and Options for Guiding Systems

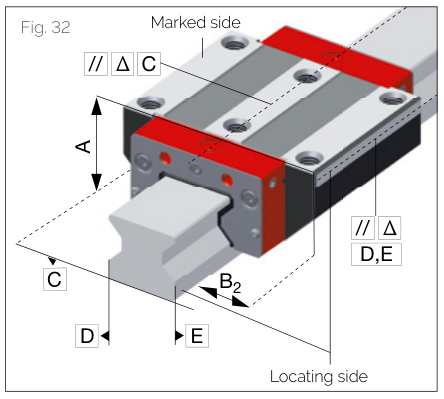

Fig. 32

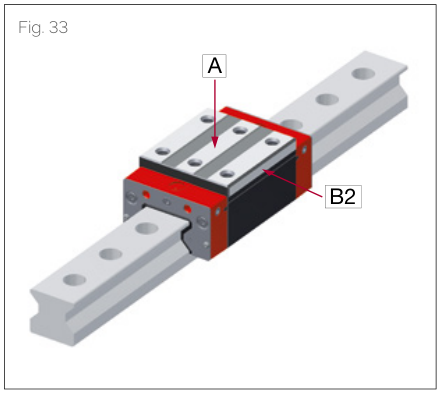

Fig. 33

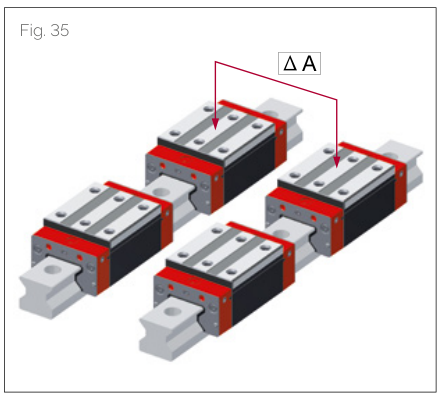

Fig. 34

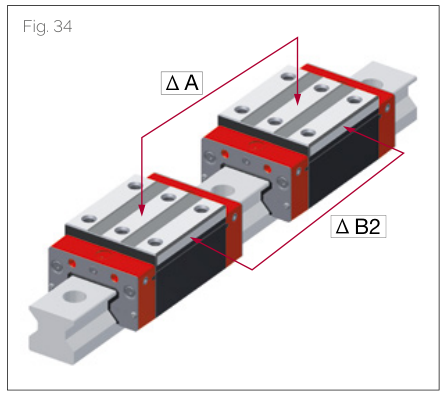

Fig. 35

Dimensional Tolerances

(Fig. 32, 33) MONORAIL carriages and rails are manufactured independently to very strict tolerances and are therefore fully interchangeable. This means any carriage can be used on any rail of the same size without affecting preload, as preload is determined by the carriage's rolling elements. For dimensional differences between any carriage on any rail, the values in the first column of the table below apply.

| Accuracy Class | Carriage and Rail Tolerance A/B2 | Max Difference for System Matched Carriages DeltaA/DeltaB2 | Max Difference for Standard Carriages DeltaA Standard |

|---|---|---|---|

| G0 | +/- 5 um | 3 um | 10 um |

| G1 | +/- 10 um | 5 um | 20 um |

| G2 | +/- 20 um | 7 um | 40 um |

| G3 | +/- 30 um | 25 um | 60 um |

Measurement Location: Measured at carriage center and any rail position

Applicable Range: Values apply only to 1 m rail length

Ball Products: Parameter values are doubled; same applies to separately delivered products

Matched Carriages

(Fig. 34, 35) All carriages in a set are installed sequentially under production specifications, with their top and side mating surfaces ground smooth. The main dimensions A and B2 are then measured on a test rail, and carriages can be matched. Matched carriages are available in two quality grades.

| Matched Carriages | Max Dimensional Difference Between Matched Carriages DeltaA/DeltaB2 |

|---|---|

| SLWGP0 | 3 um |

| SLWGP1 | 5 um |

Matched Rails

Using "matched rails," we search data to find rails with similar characteristics. The selection process criterion is the maximum deviation over the entire rail length, the so-called matching tolerance. Deviation reports for all matched rails are within this tolerance range. Matched rails are available in four quality grades.

| Matched Rails | Matching Tolerance |

|---|---|

| SLSGP0 | 5 um |

| SLSGP1 | 10 um |

| SLSGP2 | 15 um |

| SLSGP3 | 20 um |

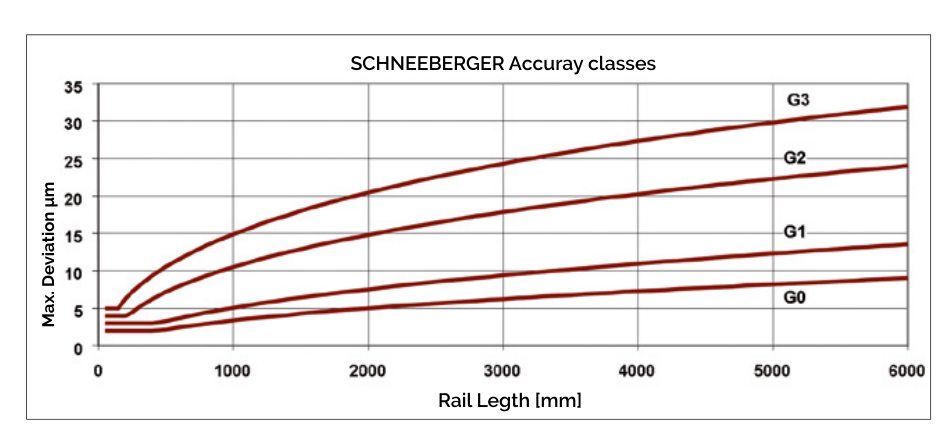

Running Accuracy

Carriage running accuracy can be linear (along a line) or fluctuating (within tolerance). The maximum allowable deviation is determined as a function of accuracy class and rail length in the diagram below.

Example: With L3 = 2000 mm and G2 accuracy class, the deviation is 0.025 mm.

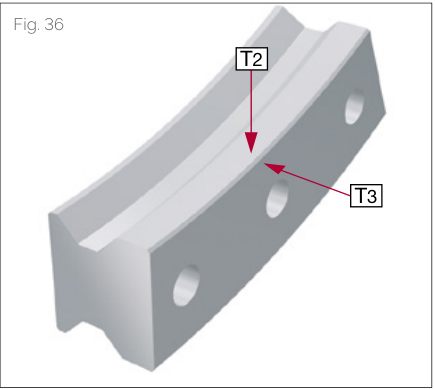

Straightness

For effective installation of profiled rail guideway sections, it is important to understand the rail straightness and the curvature of the rail side surfaces. Since side sections are flexible elements, they may deform under their own weight. Deformation may also be caused by the manufacturing process. To meet customer installation requirements, rail straightness is optimized during manufacturing.

Fig. 36 - T2: Rail top surface straightness / T3: Rail side surface straightness

In addition to standard rail straightness, SCHNEEBERGER offers special tolerances and/or inspection reports to meet specific customer requirements.

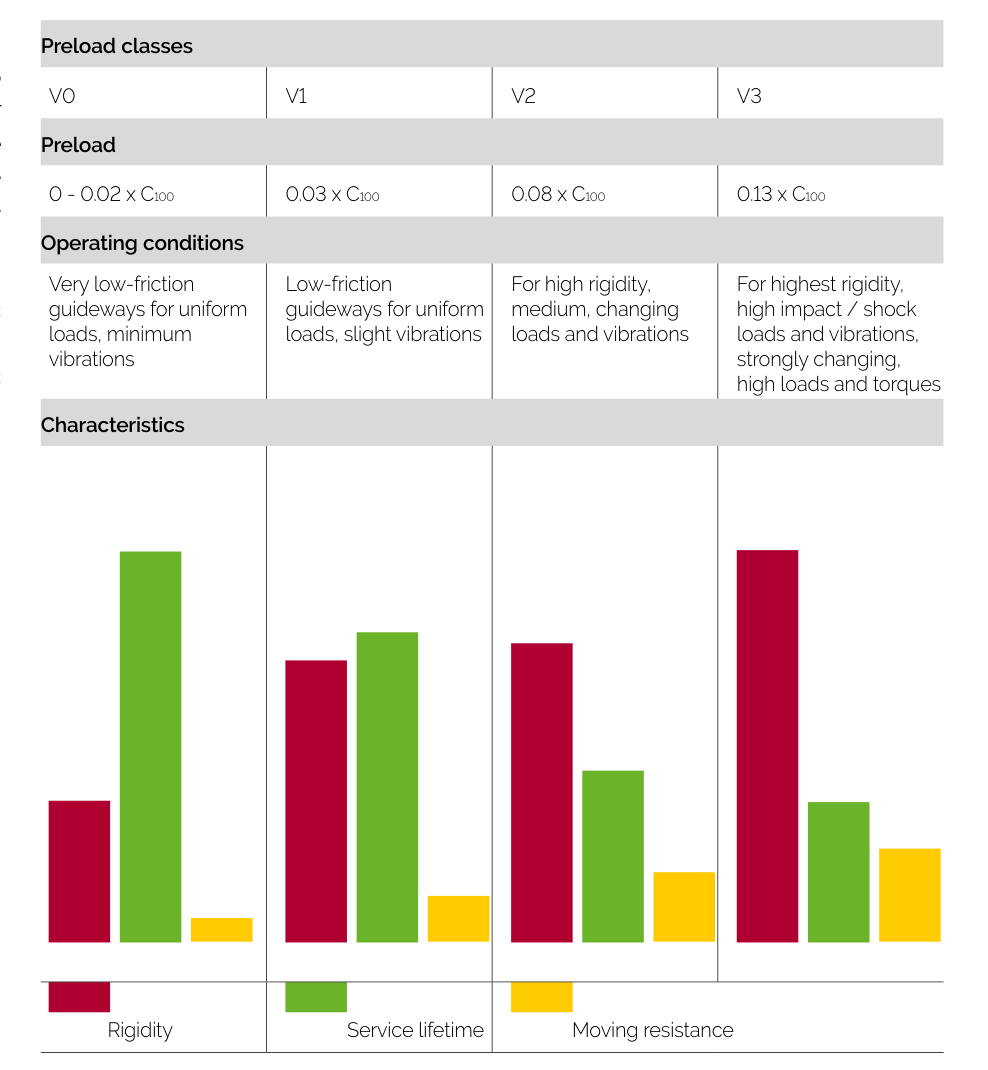

Preload Classes

Roller guideways are preloaded to enable clearance-free operation under different load conditions. Basically, preload increases system rigidity but also increases thrust. SCHNEEBERGER guideways are available in four preload classes to meet specific application requirements. Preload class depends on dynamic load capacity.

| Code | Preload Class | Preload Force (% of C0) | Operating Conditions | Characteristics |

|---|---|---|---|---|

| V0 | Very Light Preload | 0 - 2% | Low friction guideway, suitable for uniform loads, minimal vibration | Low rigidity |

| V1 | Light Preload | 3% | Low friction guideway, suitable for uniform loads, slight vibration | Long service life |

| V2 | Medium Preload | 8% | High rigidity, moderate varying loads and vibration | High rigidity and vibration resistance |

| V3 | High Preload | 13% | Maximum rigidity, impact loads, drastically varying loads | High load and high friction |

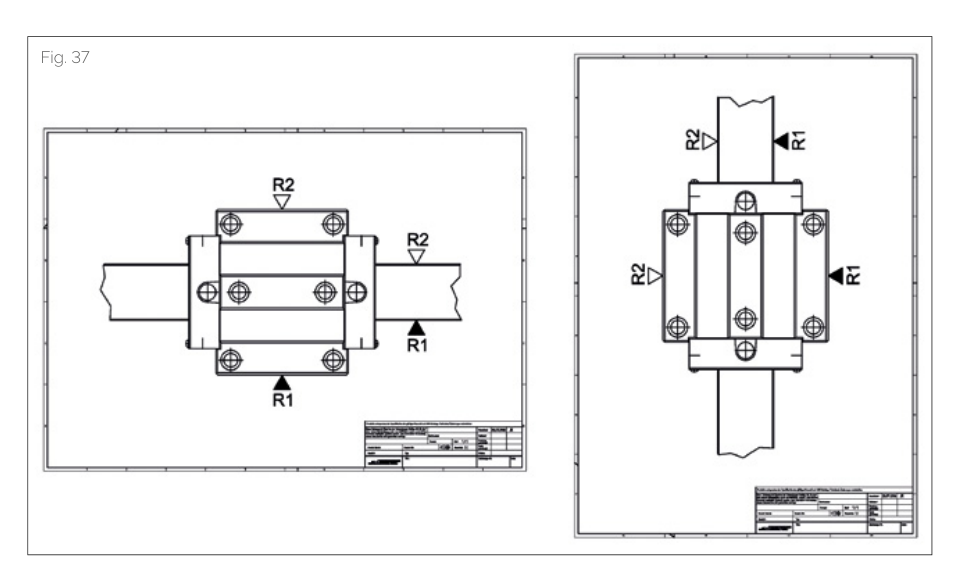

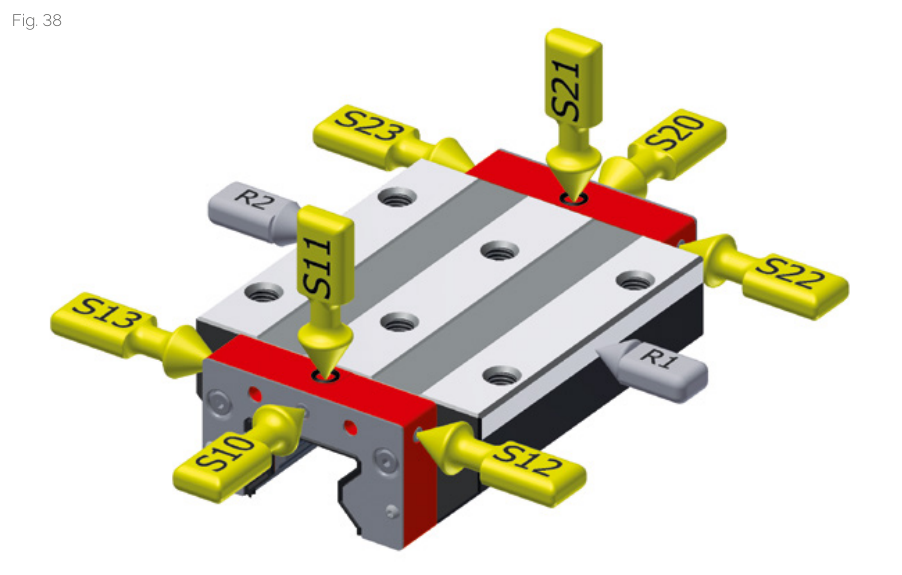

Reference Sides

Depending on the product installation conditions, the reference sides of carriages and profiled rails must be specified when ordering.

| Code | Position | Description |

|---|---|---|

| R1 | Reference at Bottom | Reference at bottom - Standard configuration |

| R2 | Reference on Top | Reference on top |

Lubrication Connections

All carriages have extensive lubrication connection options on the front plate and top. Therefore, connections can be made in the optimal way to meet lubrication supply requirements according to customer specifications. As standard, all four raceways are lubricated through one connection.

| Code | Position | Description |

|---|---|---|

| S10 | Left Center | Left center |

| S20 | Right Center | Right center |

| S11 | Top Left | Top left |

| S21 | Top Right | Top right |

| S12 | Lower Left Side | Lower left side |

| S22 | Lower Right Side | Lower right side |

| S13 | Upper Left Side | Upper left side |

| S23 | Upper Right Side | Upper right side |

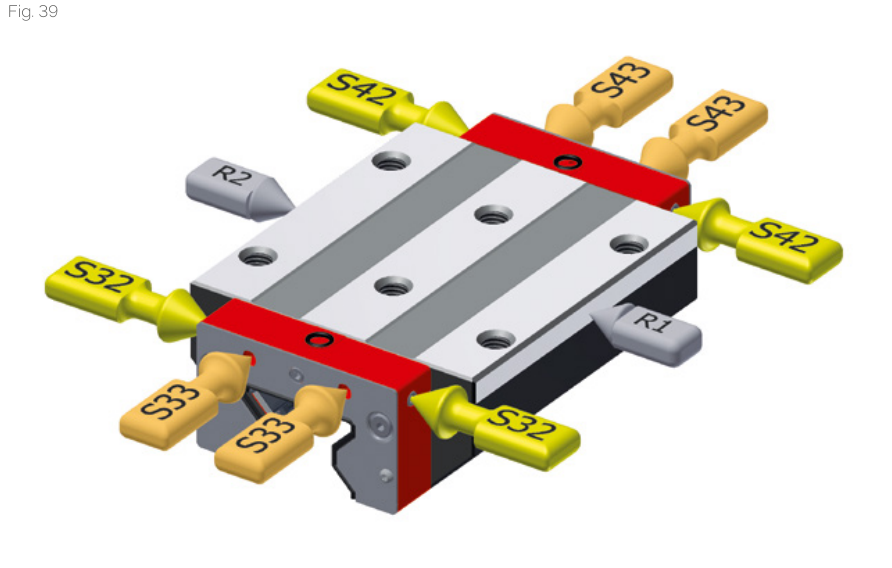

| S32 | Left Side | Left side |

| S42 | Right Side | Right side |

Separate Carriage Lubrication Connections

As a special feature, SCHNEEBERGER systems can provide separate lubrication for both sides of the carriage (S32, S42) for certain installation positions. This enhances guideway lubrication and extends machine service life.

Separate Lubrication Combination Codes

- S99: S10+S12+S13+S20+S22+S23 using threaded nipple locking

- S98: S32+S33+S42+S43 using threaded nipple locking (MR only)

- S49: For AMS with housing position P1: S10+S12+S13 using threaded nipple locking

- S49: For AMS with housing position P3: S20+S22+S23 using threaded nipple locking

Lubrication as Delivered

Carriages can be equipped with various lubricants according to application requirements. For applications providing continuous lubrication during installation and operation phases, light oiling or a thin layer of grease is sufficient. For manually lubricated applications, full grease filling is recommended.

| Code | Type | Description | Suitable Applications |

|---|---|---|---|

| LN | Oil Protection | Oil protect - Light oiling | Applications with continuous oil supply after installation |

| LG | Grease Protection | Grease protect - Thin layer of grease | Applications with continuous grease supply after installation |

| LV | Full Greasing | Full greasing - Complete grease filling | Manually lubricated applications |

Friction

Thrust is an important value in guideway system characteristics. In the case of profiled rail guideways, this largely depends on the friction of the sealing system. There are also other contributions from sliding contacts and friction when changing direction.

Application-specific factors, such as lubricant type, external load amount, and speed also have an influence. To adjust the friction of the seal type, special plastics can be used to adapt to application requirements.

Coating

For applications requiring special corrosion protection, such as cleanroom applications or high humidity environments, or when increased surface wear resistance is required, MONORAIL carriages and rails are available in hard chrome plated versions.

| Code | Type | Features |

|---|---|---|

| - | Standard (no coating) | Standard steel surface |

| CN | Hard Chrome Plating |

|

Note

Holes, threads, and rolling elements are not chrome plated.