MONORAIL System Features

Features of the MONORAIL System

Guideway System Features

The SCHNEEBERGER MONORAIL system employs multiple innovative designs to deliver outstanding performance and reliability.

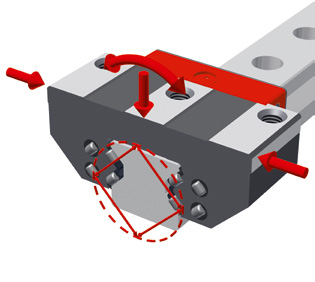

O-Type Geometry

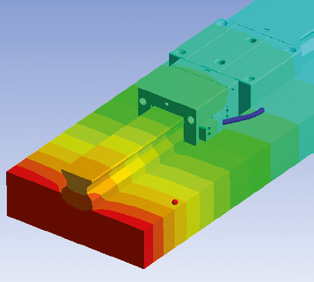

Four load-bearing surfaces arranged in O-type configuration, matching the rail's O-type arrangement. This configuration absorbs loads uniformly in all four directions and provides extremely high moment rigidity.

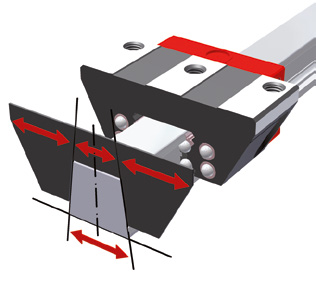

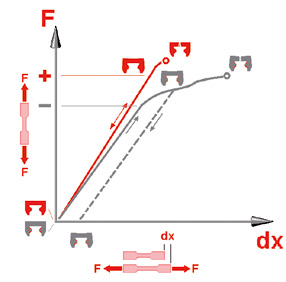

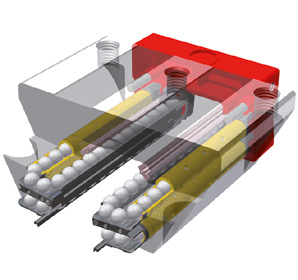

Convex Roller Design

Linear guideways significantly impact overall machine rigidity. MONORAIL MR achieves high rigidity through rollers with convex profiles and optimized raceway cross-sections for rolling elements and carriages. Compared to ball guideways, roller guideways have larger contact areas, enabling higher load capacity with minimal rolling friction.

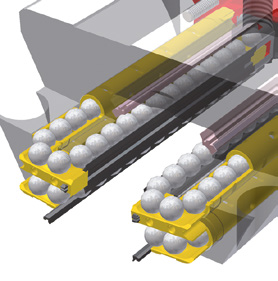

Ball Two-Point Contact

MONORAIL BM uses ball design as an O-type geometry ball guideway. Even under preload and load, balls have only two opposing contact points in the raceway area. Compared to four-point contact guideways, friction is significantly reduced, allowing balls to run more smoothly and uniformly.

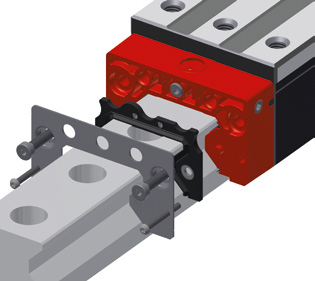

Trapezoidal Rail Profile

The trapezoidal rail profile allows carriages to be optimally serviced on the rail, as they can be replaced directly on the track without complex carriage removal procedures.

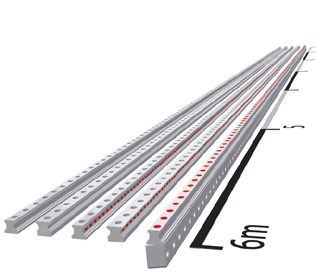

Single Length up to 6 Meters

SCHNEEBERGER offers rails in single lengths up to 6 meters. Therefore, fewer rail joints are required. This not only simplifies assembly work but also provides higher accuracy and extends system service life.

Fully Hardened Carriage

The carriage steel body is a key component for achieving long service life and constant accuracy. To withstand extreme loads without plastic deformation, SCHNEEBERGER uses premium hardened raceways. Not only the rolling surfaces but the entire carriage steel body is hardened. Even under loads exceeding recommended limits, MONORAIL carriages maintain their specifications without plastic deformation.

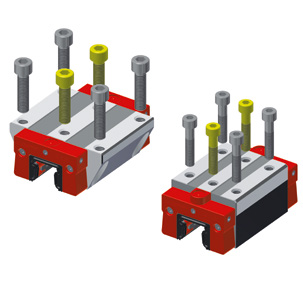

6 Fixing Holes per Carriage

When carriages are subjected to tensile forces, rigidity largely depends on their connection to the supporting structure. To achieve maximum rigidity, all SCHNEEBERGER carriages have threaded fixing holes on the carriage top.

Unique Running Characteristics

Special attention is paid to rolling element movement from the carriage return zone. Raceways are geometrically optimized to provide extremely smooth running: minimal travel fluctuation, pitching motion, and stability at both low and high speeds.

Sealing and Lubrication Features

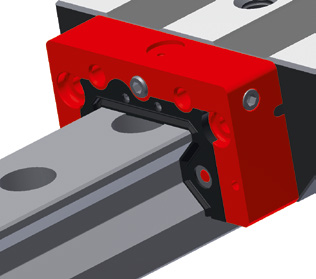

Complete Sealing

MONORAIL carriages are equipped with a double-lip sealing system, consisting of an external scraper on the front plate and an internal labyrinth seal on the carriage steel body. In many applications, especially machine tools, reliable protection against contaminants (such as metal chips) entering the raceways is a decisive factor for long system service life.

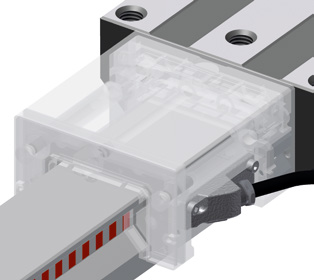

Synthetic Material Circulation Parts

The return channels for rolling elements significantly affect carriage operation. Therefore, all SCHNEEBERGER products are equipped with synthetic material circulation parts. Besides noise reduction, the synthetic parts are designed as additional lubricant reservoirs. The extra lubricant can significantly extend carriage maintenance intervals.

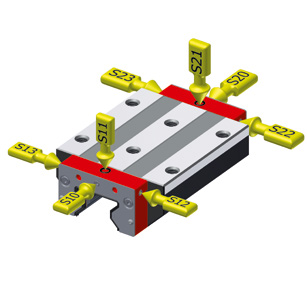

Multi-functional Lubrication Connections

All carriages have lubrication connection holes on both sides of the front plate, both sides of the top, and optionally on the top. This allows lubrication supply to be connected in the optimal way according to customer specifications. Depending on installation position, both sides of the carriage can be lubricated separately.

Visible Lubricant Distribution

The visible configuration eliminates any possibility of confusion. In the standard lubrication distribution system, all four nipples are connected to holes and internal channels on the front plate. Lubricant is distributed simultaneously to the right and left raceways. When using separate carriage lubrication nipples, two lubrication connections are used, supplying the right and left raceways separately.

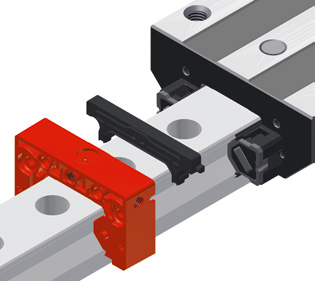

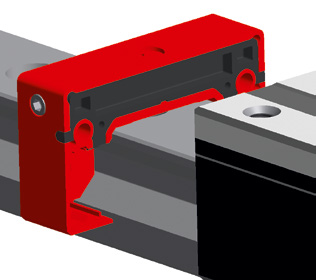

Replaceable Wipers

Transverse wipers are installed in separate elements on the front plate and can be removed in the axial direction without deformation after the front plate is removed. The protrusion in the center of the front plate allows easy wiper replacement without any problems between two carriages.

Stainless Steel Front Plate

The front plate covers and protects the end plate and is firmly connected to the steel body by four screws. The exterior of the front plate is thus protected from environmental influences. The front plate also ensures precise installation of accessories (such as additional wipers or lubrication plates).

Pressure-Resistant Lubrication Channels

Lubricant is firmly connected to the front plate by ultrasonic welding, forming enclosed internal channels with the components. Lubricant applied through pipe connections can reach the rolling elements and lubricant reservoirs even when the carriage is stationary. This ensures adequate lubricant distribution even under high pressure.

Integrated Measuring System Features

Integrated Rack

The MONORAIL BZ system provides a premium rack integrated into the guideway. Because the rack is integrated into the rail, long stroke lengths can be achieved with high precision requirements. The integrated structure reduces manufacturing, assembly, and adjustment time, significantly saving costs compared to systems with separately installed racks. Machines can now be equipped with two rail combinations, eliminating any time-consuming adjustment work between the guiding system and rack.

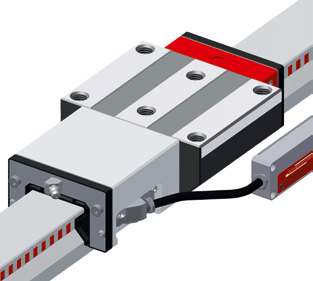

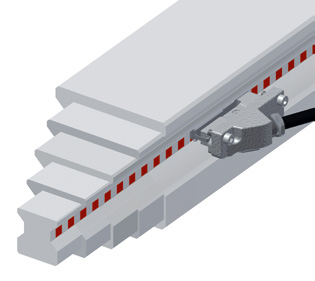

Integrated Linear Scale

Combining a high-precision linear encoder with MONORAIL guideways simplifies installation and adjustment when designing, manufacturing, and maintaining machines, greatly reducing complexity compared to machines using separate linear scales.

Magneto-Resistive Measuring Principle

The sensor is based on a specially developed magneto-resistive measuring process. When relative motion occurs between the sensor and measuring scale, field strength changes cause resistance changes that are easy to measure. Any interference caused by temperature, superconducting magnetic fields, displacement and angle are minimized in the conversion circuit, meaning the sensor function is largely position-independent, requiring no adjustment work after read head replacement.

Process-Close Position Measurement

Good thermal connection between the measuring system and machine bed is paramount; first, by firmly connecting the integrated measuring scale to the rail; second, by firmly fixing the rail to the machine bed. The benefit of machine bed temperature changes is directly transferred to the measuring system. Good thermal interconnection between measuring standard and rail, and the machine bed means these machines require no reference points or temperature sensors for process stability.

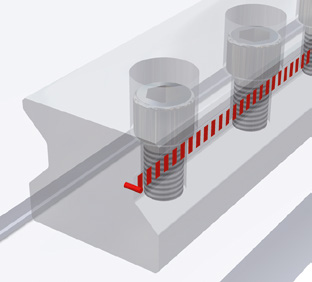

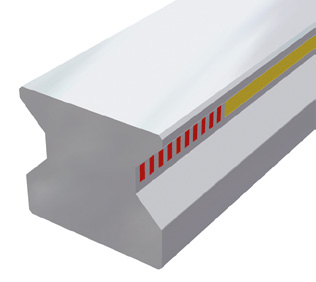

Steel-Like Thermal Expansion

The magnetic measuring scale is mounted in a groove on the side of the rail. The measuring standard material has the same expansion coefficient as the rail, and therefore the same as the machine bed. Therefore, no temperature compensation is required when replacing paired steel parts.

One Read Head for All Sizes

The measuring scale position is the same across all product groups. The new generation read head provides enhanced vibration resistance with EMI shielding. Connections between parts are also resistant to chemical corrosion. This ensures SCHNEEBERGER AMS products maintain their characteristics even in areas easily exposed to water coolant or other chemicals.

Protected Measuring Scale

After production, the integrated measuring scale is protected from mechanical damage and magnetic interference by an externally hardened non-magnetic cover welded to the rail, tightly protecting the measuring scale from chips and coolant, and is very robust and reliable.

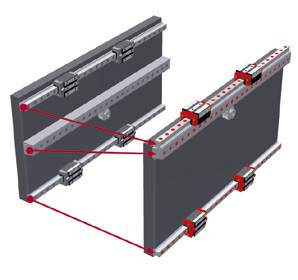

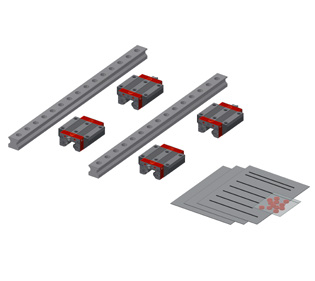

Complete Axis Set Supply

If required, SCHNEEBERGER products can be supplied as complete sets. This means customers receive complete rail and carriage assemblies inspected according to their requirements. Basic tasks handled by customers include assembly, alignment to surrounding structures, carriage installation, connection to drive elements and lubrication systems, and sensor system connection to the control system.