1.8.1 Function of Seals

The seals on SCHNEEBERGER MONORAIL guideways protect the carriage and rolling elements from foreign matter ingress, such as dust, chips, and coolant.

To ensure optimal function of the guideway seals, the following factors are crucial:

- Complete configuration and correct installation of scrapers

- Supplying lubricant to the sealing lips to prevent stick-slip effect, lip rollover, and wear

- Using the smoothest possible wiping surfaces, avoiding protruding edges (e.g., using ground surfaces and rails with smooth surfaces)

1.8.2 Seal Types

Transverse Scrapers

Transverse scrapers seal the carriage at the front end in the direction of motion. The scrapers are located at both ends of the carriage. Thin, friction-optimized sealing lips point inward to minimize lubricant discharge.

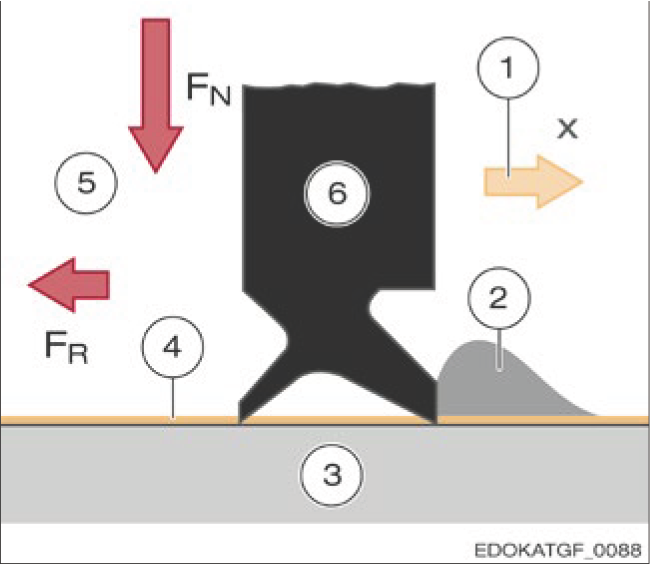

Transverse scrapers are designed as contact seals. This means that reliable operation requires normal force FN, which generates friction force FR.

Function of the transverse scraper (cross-section) in the direction of motion (orange arrow x). FN = Normal force, FR = Friction force

Legend:

Longitudinal Scrapers

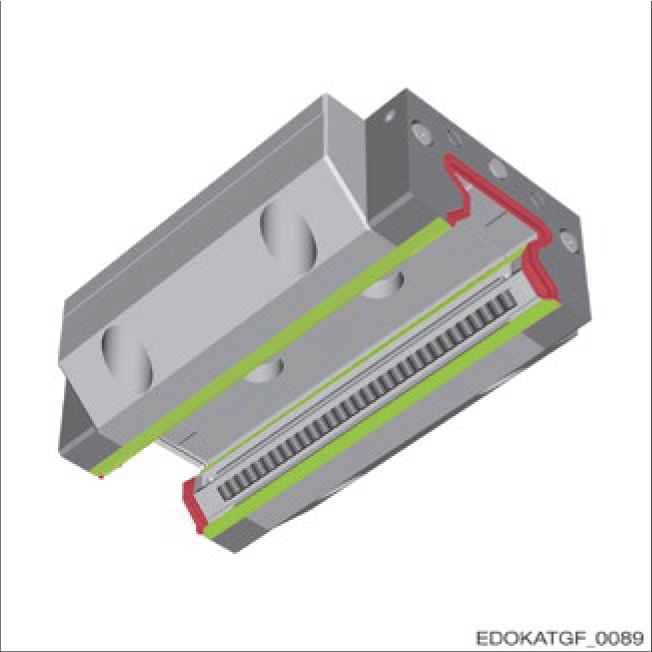

Longitudinal scrapers are seals arranged in the direction of motion, used to seal the rolling element recirculation channels.

Longitudinal scrapers (green) and transverse scrapers (red) on the carriage

Smooth-Running Transverse Scrapers

Smooth-running transverse scrapers are used to reduce thrust in applications with less contaminant accumulation. This design optimizes friction characteristics while maintaining basic sealing function.

Additional Transverse Scrapers

Under special working conditions, such as severe contaminant accumulation, chip impact, or coolant influence, additional sealing devices can be installed.

1.8.3 Friction of Different Seals

For contact seals, there is a direct relationship between friction force FR and sealing efficiency. Good sealing efficiency typically means higher friction force.

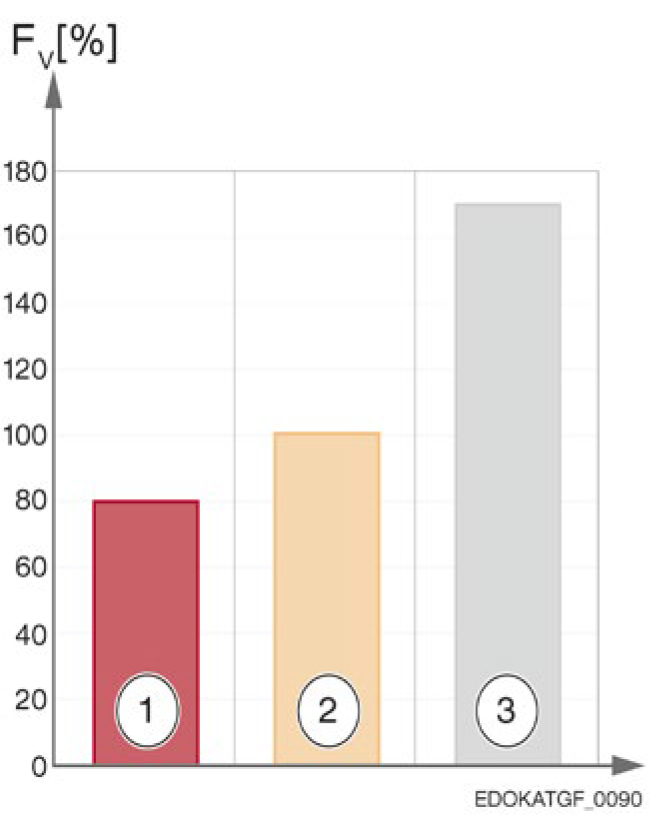

Comparison of driving force FV (%) for different scraper variants on ball guideway BM 35 example

Legend:

Y-axis: FV [%] - Driving force (percentage relative to standard scraper)

Note: Higher values indicate greater friction force but better sealing effect

Selection Recommendations

Seal selection should be based on actual working environment. Excessive sealing increases friction force and cost, while insufficient sealing leads to premature wear. It is recommended to consult SCHNEEBERGER technical personnel for optimal recommendations.