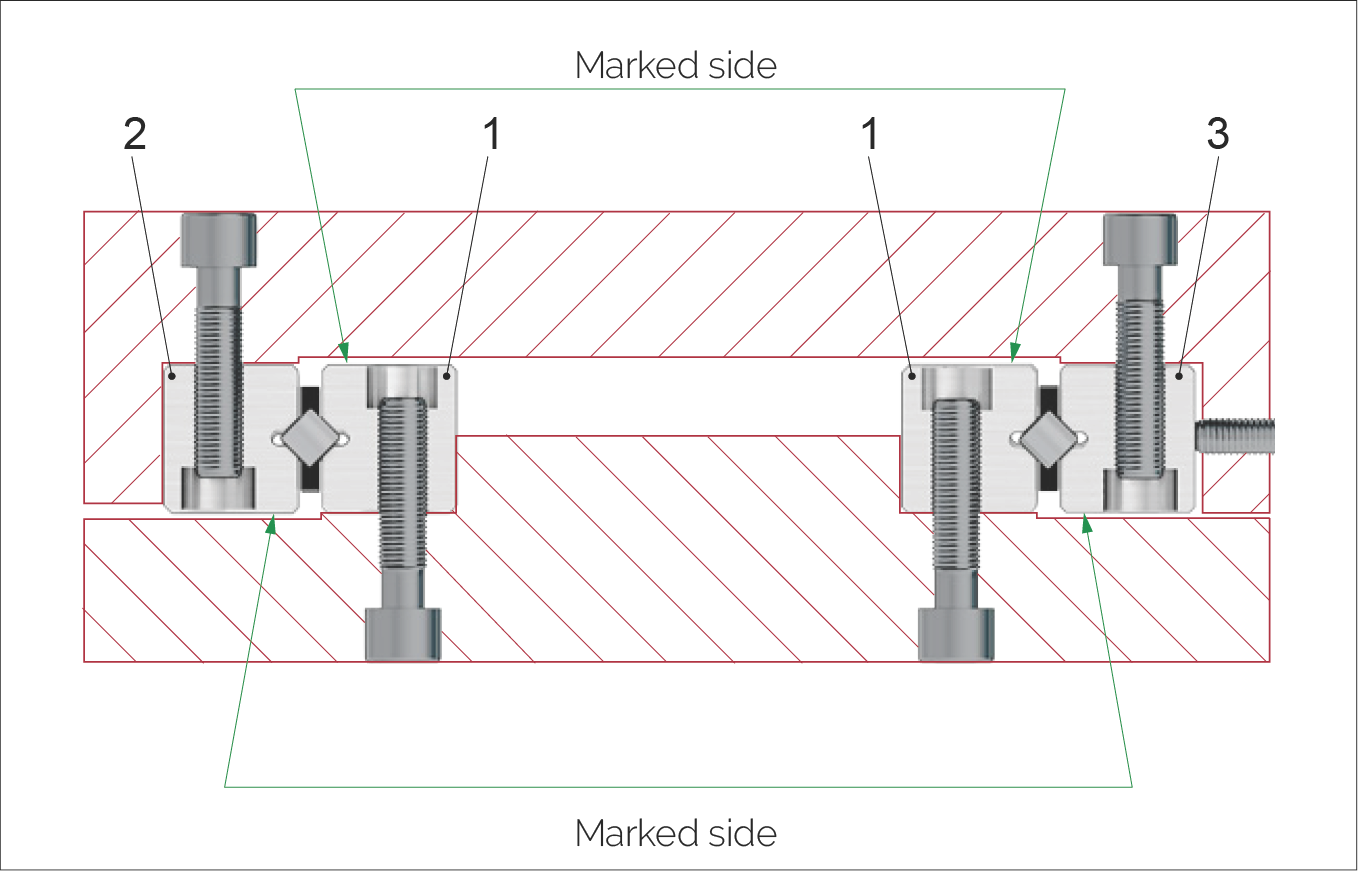

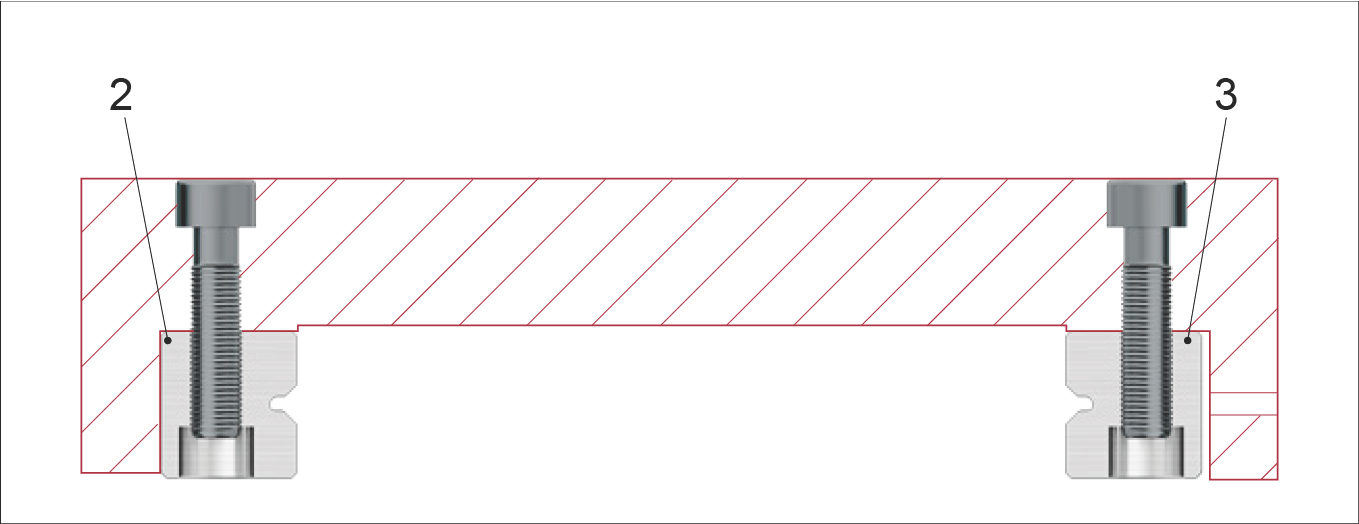

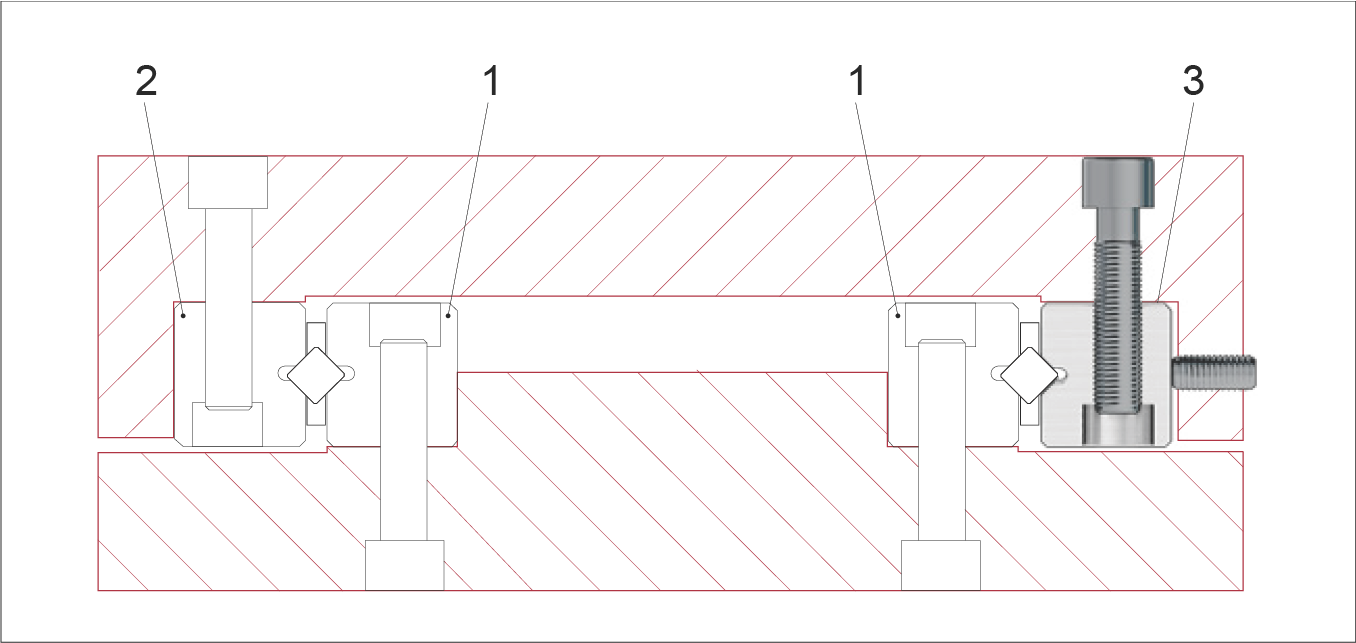

Linear guideway installation cross-section diagram - Marked side indication

Linear Guideways

Through careful, clean preparation and a step-by-step approach with a logical procedure, you will be able to achieve a perfect guideway system.

The following installation instructions apply to all types of SCHNEEBERGER linear guideways.

Preparation

- To ensure perfect support of the guideway, any remaining burrs or protrusions should be removed using a fine grinding stone.

- Before installation, the linear guideways and support surfaces should be cleaned. Through subsequent light lubrication, they will be protected against any subsequent damage.

- The marked side of the guideway must not be used as a support surface!

Due to hole tolerances in the guideway, fixing holes on the support surface should be drilled according to the holes in the linear guideway. By using fixing screws with fine shafts, differences in hole spacing can also be adjusted (see Chapter 5).

Install Fixed Linear Guideway Pair

The fixed linear guideway pair (1) is pressed against the support using appropriate clamping elements and the fixing screws are tightened (use a torque wrench! For tightening torques, see Chapter 13.5).

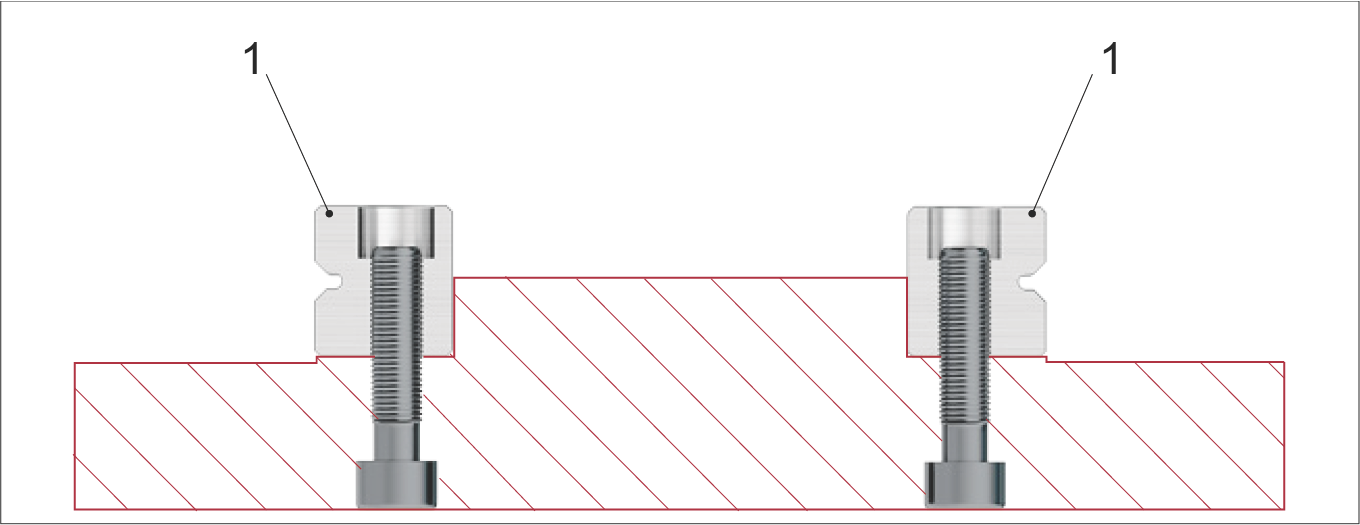

Installation step for fixing one pair of linear guideways (1)

Check Parallelism

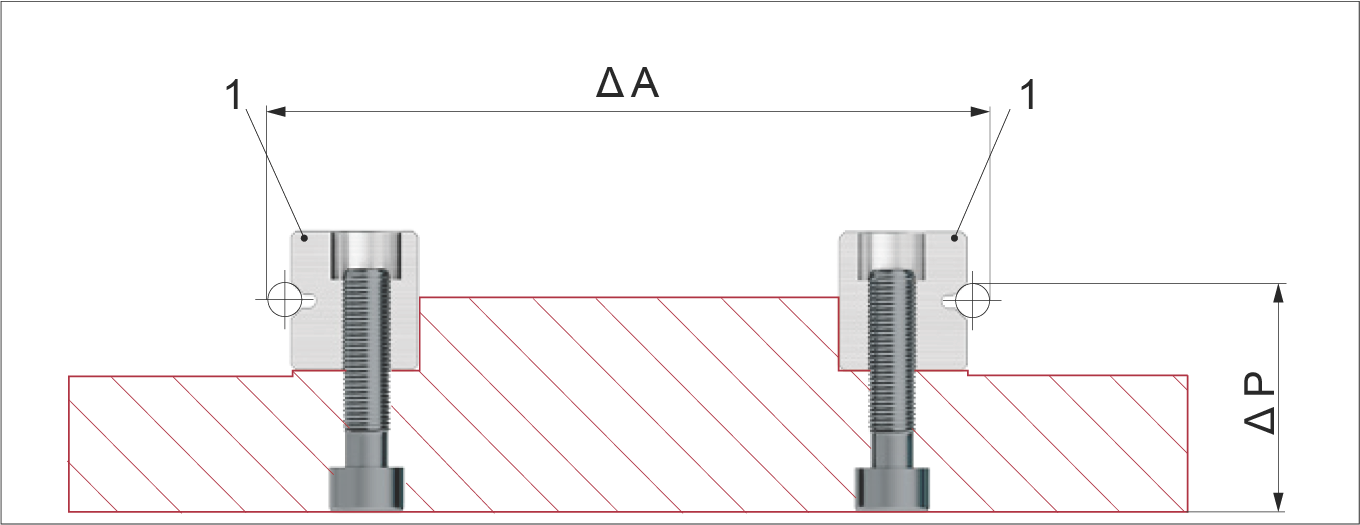

Check parallelism ΔA and ΔP. The measured parallelism must be within the tolerance range of the linear guideway (see Chapter 7.1).

Check parallelism ΔA (horizontal distance) and ΔP (vertical height difference)

Install Opposing Fixed Guideway

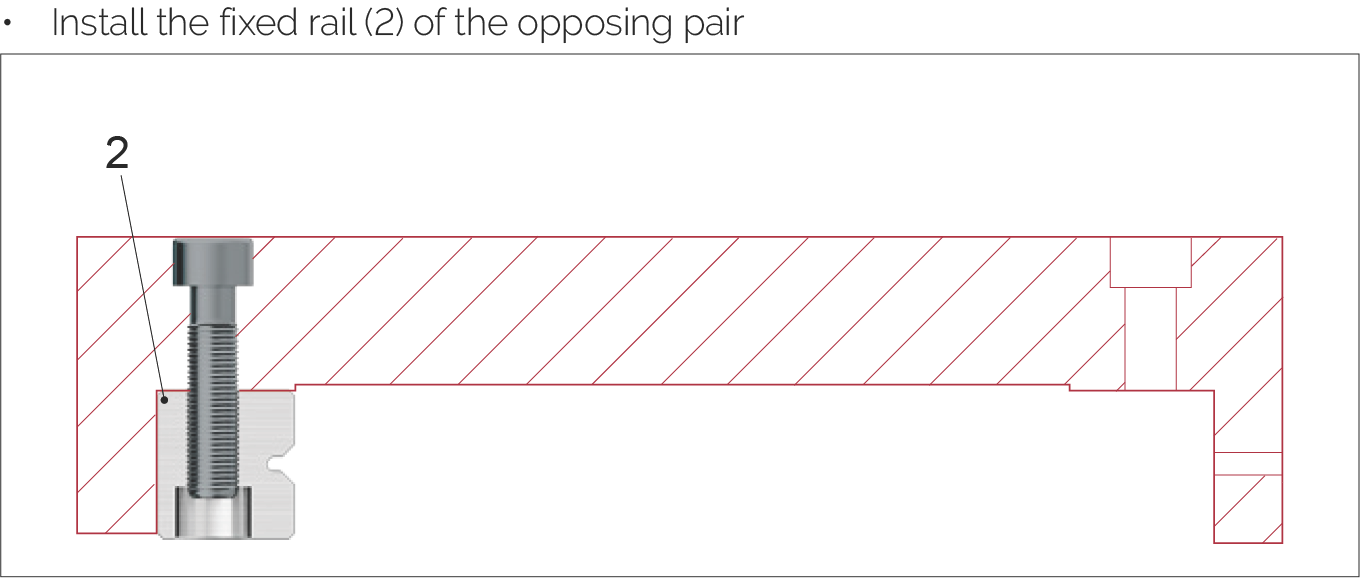

Install the fixed guideway (2) on the opposite side.

Install the fixed guideway (2) on the opposite side

Install Guideway and Lubricate

Install guideway (3), only slightly tightening the fixing screws during this process. Perform lubrication (see Chapter 13.8).

Install guideway (3) and slightly tighten fixing screws, perform lubrication

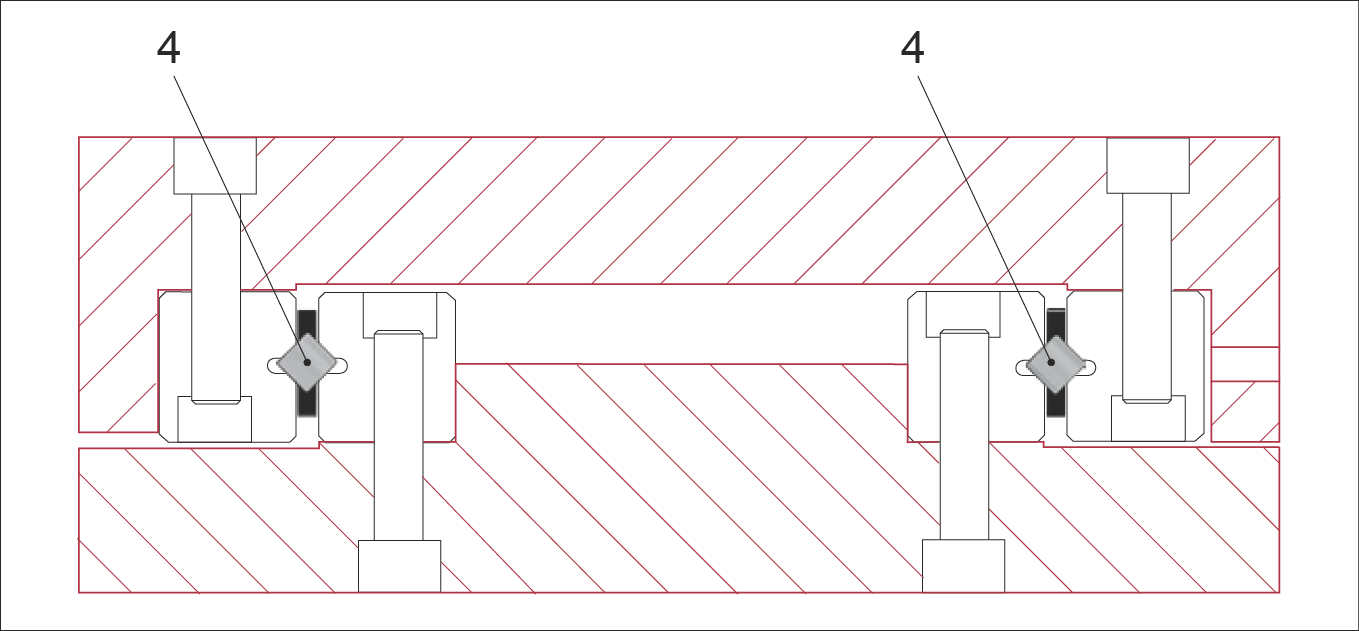

Insert and Center Cages

Insert and center cages (4). After this, the linear bearing must be preloaded (see next page).

Insert and center cages (4), prepare for preloading

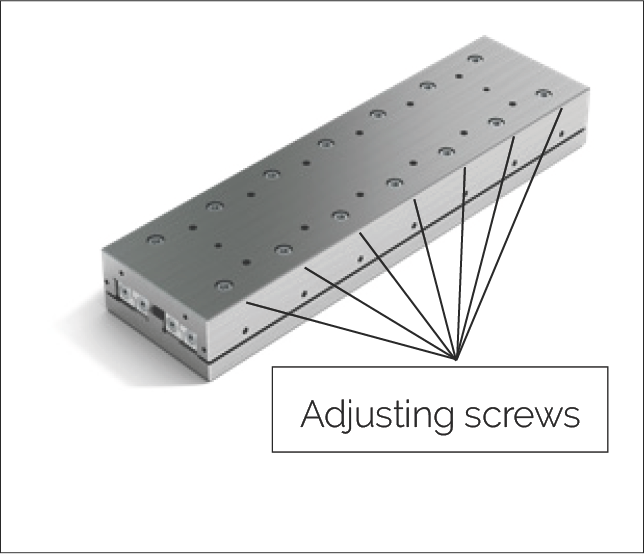

Set and Preload Linear Guideway

Set and/or preload the linear guideway to achieve zero clearance (see Chapter 13.5).

Set and preload linear guideway using adjusting screws

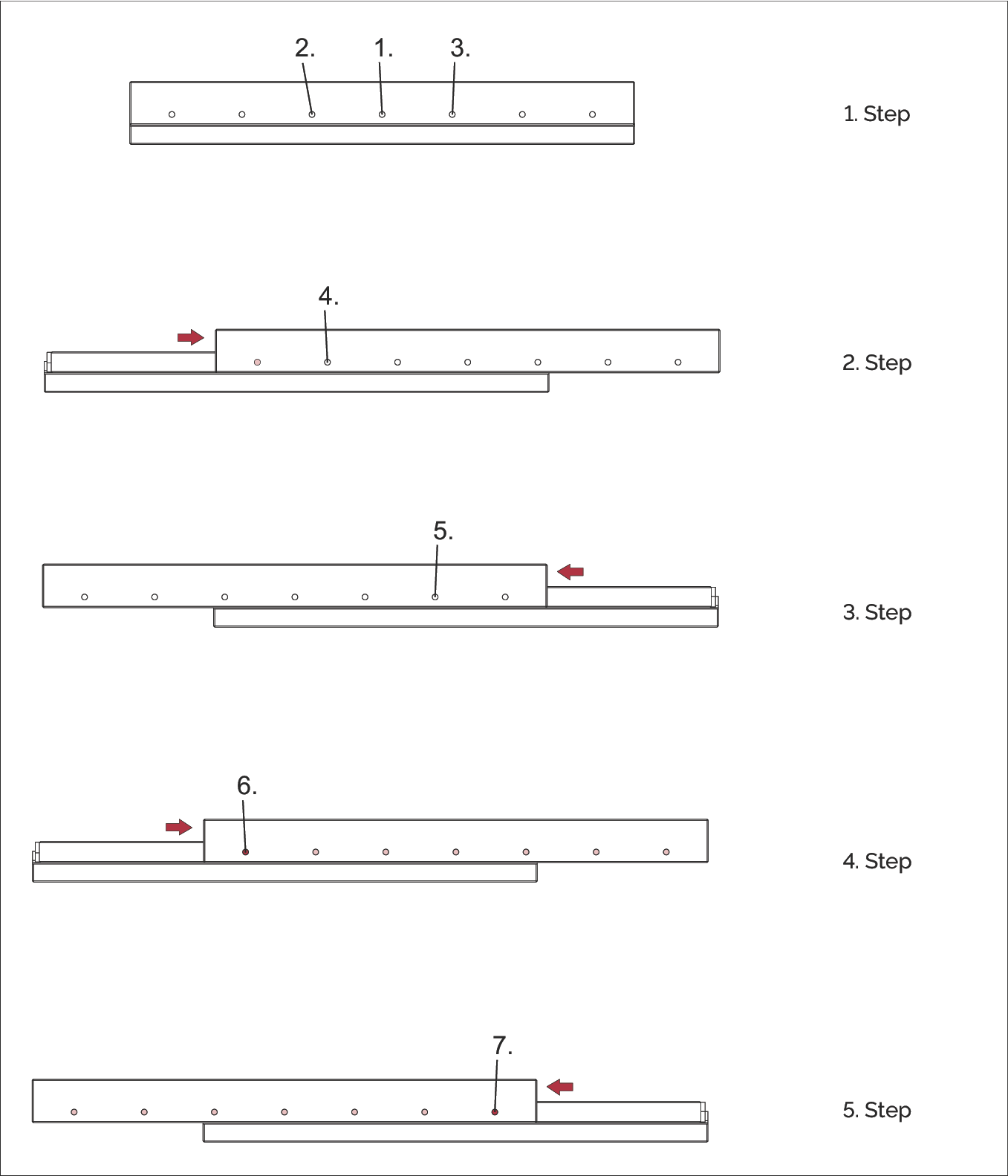

Apply Preload Sequence

Preload application using adjusting screws should proceed from the center of the guideway outward, following these steps (sequence can be seen from the diagram):

Five steps for applying preload from the center of the guideway outward

Tighten Screws and Install End Pieces

Tighten the fixing screws of guideway (3) and install end pieces.

Tighten guideway fixing screws and install end pieces

Ordering Examples

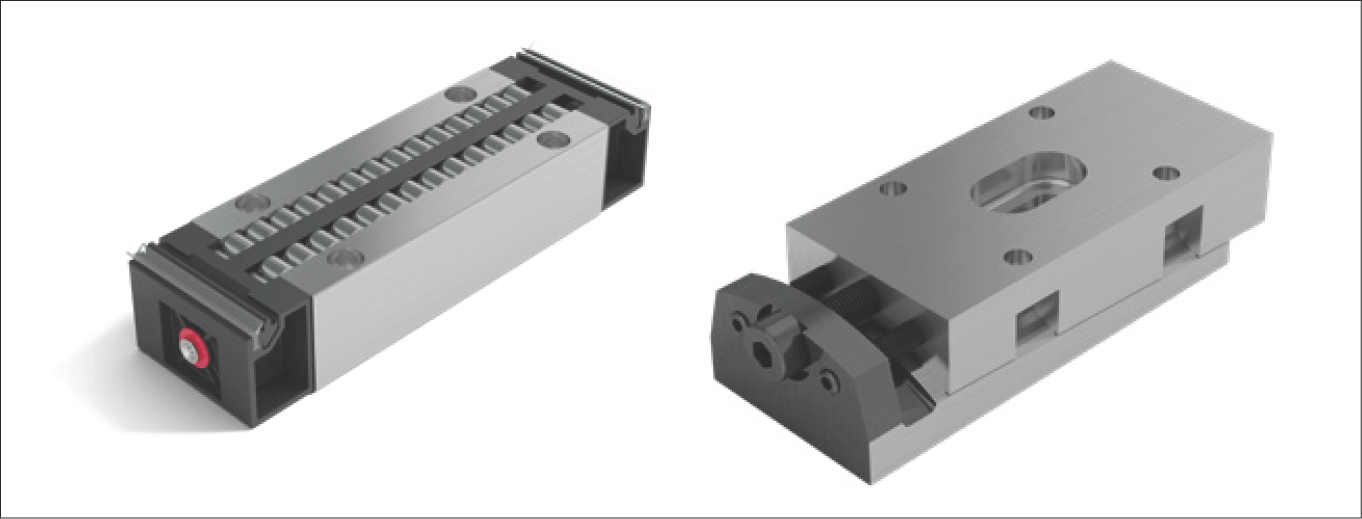

Linear Guideway Example

Example 1 - Kit Composition

| Quantity | Type and Size | Length (mm) | Options |

|---|---|---|---|

| 4 | RNG 6 | 300 | RF-SSQ-KS |

| 2 | KBS 6 x 20* | - | RF |

* Corresponding number of rolling elements

Set RNG 6-300-RF-SSQ-KS; KBS 6x20-RF includes:

- 4 pcs Linear guideway RNG 6-300-RF-SSQ-KS

- 2 pcs Cage KBS 6x20-RF

Example 2 - Kit Composition

| Quantity | Type and Size | Length (mm) | Options |

|---|---|---|---|

| 2 | R 9 | 800 | - |

| 2 | R 9 | 600 | EG |

| 2 | AC 9 x 22* | - | - |

| 8 | GC 9 | - | - |

* Corresponding number of rolling elements

Set R 9-800/600-EG; AC 9x22; GC 9 includes:

- 2 pcs Linear guideway R 9-800

- 2 pcs Linear guideway R 9-600-EG

- 2 pcs Cage AC 9x22

- 8 pcs End piece GC 9

For cage types HW and SHW, cage length must be indicated (in mm)!

Example: SHW 20 x 155 mm

Recirculating Unit Example

Recirculating Unit Kit Composition

| Quantity | Type and Size | Options |

|---|---|---|

| 150 | NRT 26111 | GP |

| 150 | NRV 26111 | - |