6.6 Short Strokes

The effects of short strokes include point compression on the track and insufficient lubrication. Therefore, short strokes reduce the service life of the guideway. This can only be reliably determined through experimentation.

6.6.1 Short Strokes with MINISLIDE

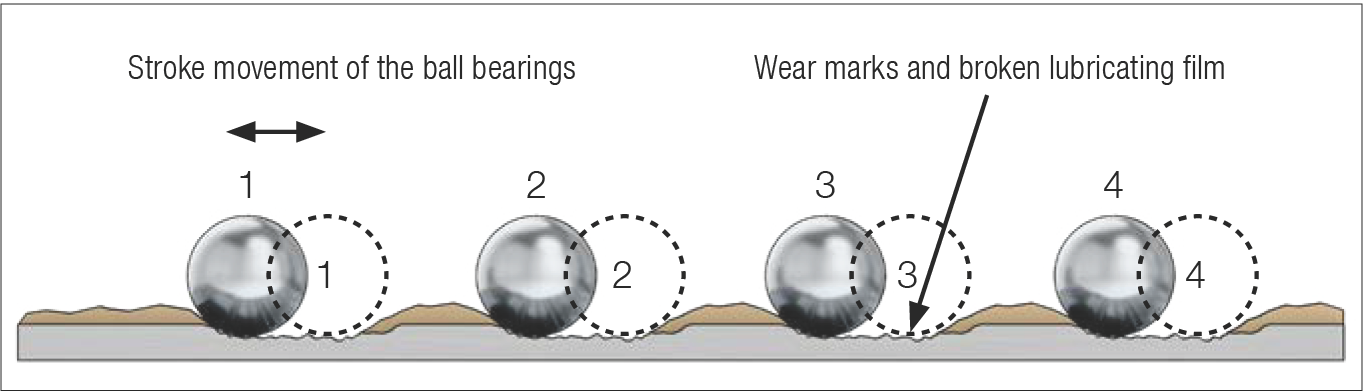

Stroke movement of ball bearings - Wear marks and broken lubricating film

The stroke length of the guideway is so low that the rolling elements cannot pass through the position of the next rolling element. As a result, localized wear marks form on the track. Excessive stress on the track from short strokes leads to material damage, which inevitably results in preload loss. Therefore, the precision of the guideway may be reduced, leading to premature failure.

Additionally, high-frequency strokes break the lubricating film, further exacerbating wear. Using suitable lubricants and performing regular strokes along the entire stroke length can achieve better lubrication and delay the effects of material wear.

6.6.2 Short Strokes with MINIRAIL and MINISCALE PLUS

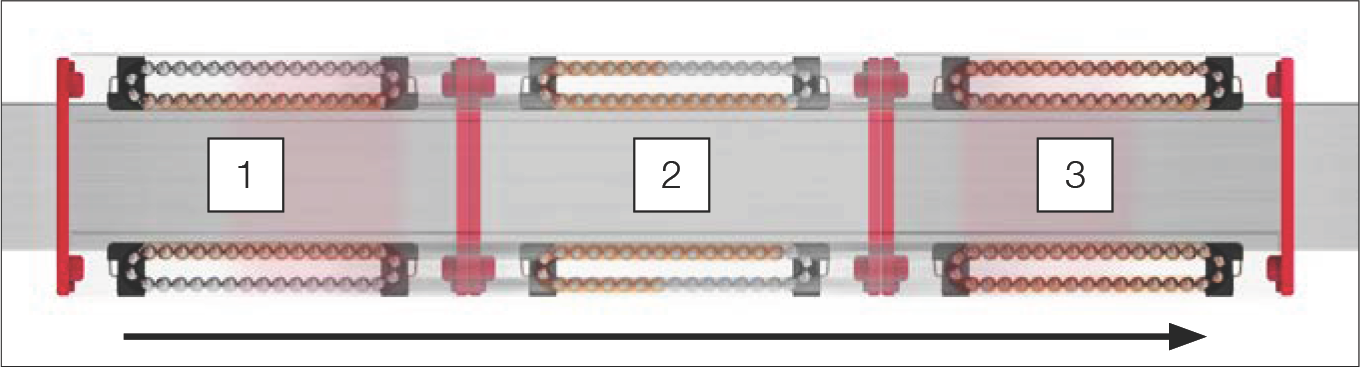

In the starting position (1), only the ball bearings directly under load are lubricated. Once the carriage moves to the right (2), part of the ball bearings absorb lubricant through the guide rail. Only when reaching position 3 are all ball bearings and all four corners of the ball circulation lubricated.

Lubrication positions: 1, 2, 3

Short strokes refer to carriage strokes less than twice its length. This can cause damage, especially in the redirection unit. Regular lubrication strokes along the entire stroke length (at least twice the carriage length) ensure better lubricant distribution and protect the guideway from premature wear.

We recommend using LUBE-S long-term lubrication for short strokes (see Chapter 8.1).