15.4 Geometric and Position Accuracy of Base Surfaces

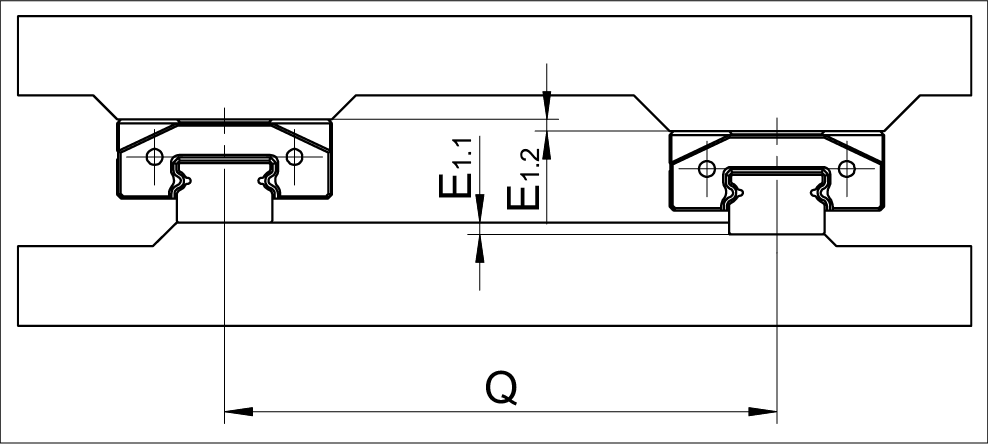

15.4.1 Permissible Lateral Deviation E1 for MINIRAIL and MINISCALE PLUS

Lateral deviation E1 measurement diagram

Calculating Height Deviation E₁

E₁ = Q · Vvsp

| E₁ | = | Height deviation E₁₁ + E₁₂, unit: mm |

| Q | = | Guide rail spacing, unit: mm |

| Vvsp | = | Preload factor (see table below) |

Preload Factor Vvsp

| Carriage Size | Preload Class V0 | Preload Class V1 |

|---|---|---|

| 7, 9, 12, 15 | 0.00025 Q | 0.00015 Q |

| 14, 18, 24, 42 | 0.00013 Q | 0.00008 Q |

E₁ Calculation Example

Spacing Q = 120 mm

0.00015 × 120 mm = 0.018 mm

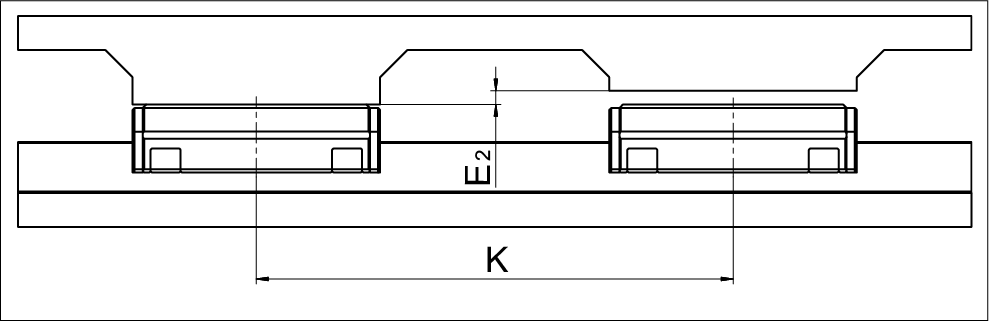

15.4.2 Permissible Longitudinal Deviation E2 for MINIRAIL and MINISCALE PLUS

Longitudinal deviation E2 measurement diagram

Calculating Height Deviation E₂

E₂ = K · Vvsp

| E₂ | = | Height deviation E₂₁ + E₂₂, unit: mm |

| K | = | Carriage spacing, unit: mm |

| Vvsp | = | Preload factor (see table below, by carriage type) |

Preload Factor Vvsp (by Carriage Type)

| Carriage Size | Carriage Type | Preload Factor Vvsp |

|---|---|---|

| 7, 9, 12, 15 | MNNS (Short) | 0.00010 K |

| 7, 9, 12, 15 | MNN (Standard) | 0.00005 K |

| 14, 18, 24, 42 | MNN (Standard) | 0.00004 K |

| 7, 9, 12, 15 | MNNL (Long) | 0.00004 K |

| 14, 18, 24, 42 | MNNL (Long) | 0.00003 K |

| 7, 9, 12, 15 | MNNXL (Extra Long) | 0.00003 K |

E₂ Calculation Example

Carriage spacing K = 700 mm

0.00003 × 700 mm = 0.021 mm

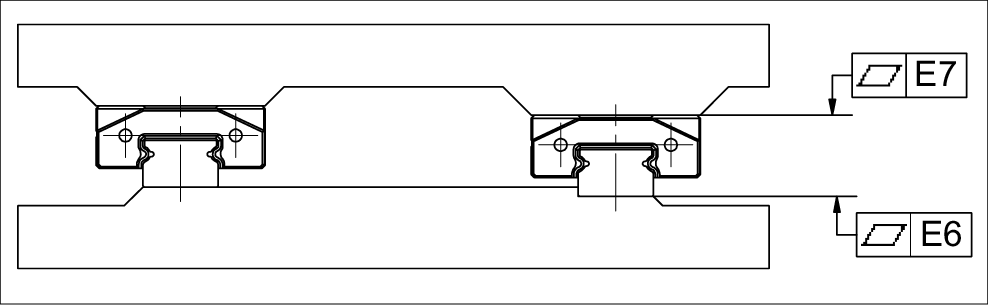

15.4.3 Flatness E6 and E7 of Mounting Surfaces

Mounting surface flatness measurement diagram

For the flatness E6 of the guide rail surface over its entire length, it is recommended to refer to the running accuracy values of the corresponding accuracy class as described in Chapter 7.2.4.

For the flatness E7 of the carriage surface, target the values in the table below.

MINIRAIL and MINISCALE PLUS

| Size | Flatness (μm) |

|---|---|

| 7 | 3 |

| 9 | |

| 12 | |

| 15 | 4 |

| 14 | |

| 18 | |

| 24 | 5 |

| 42 |

MINISLIDE MS and MSQ

For the flatness E7 of the carriage surface, target the values in the table below.

| Size | Flatness (μm) |

|---|---|

| 4 | 2 |

| 5 | |

| 7 | 3 |

| 9 | |

| 12 | 4 |

| 15 |

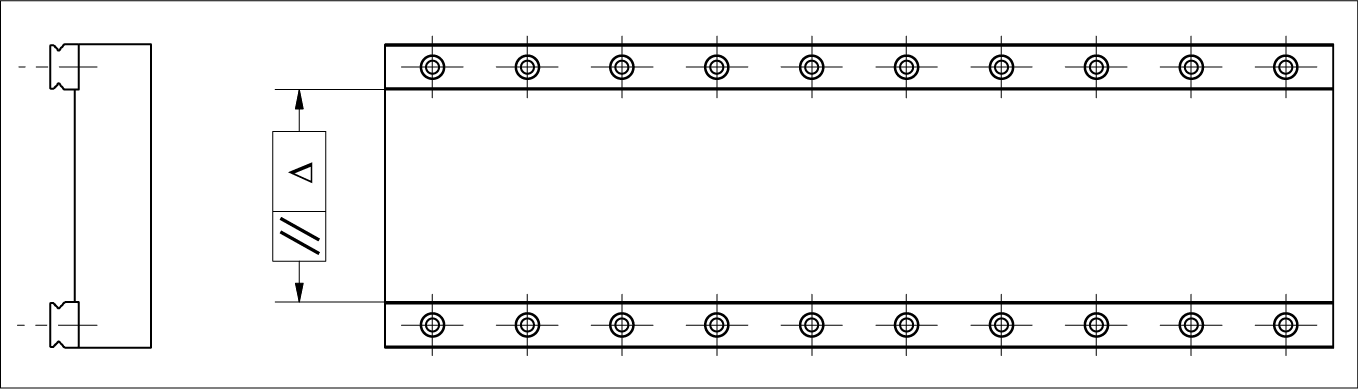

15.4.4 Parallelism Tolerance of Reference Surfaces for MINIRAIL and MINISCALE PLUS

Reference surface parallelism tolerance measurement diagram

Non-parallel aligned guide rails generate unplanned loads over the travel length of the guideway system, subjecting the rails to additional stress. This reduces the running accuracy of the guideway and may shorten service life. Therefore, the following parallelism tolerances Δ must be observed.

| Preload Class | Guide Rail Width (mm) | |||

|---|---|---|---|---|

| 7 and 14 | 9 and 18 | 12 and 24 | 15 and 42 | |

| V0 | Δ 0.003 mm | Δ 0.005 mm | Δ 0.008 mm | Δ 0.010 mm |

| V1 | Δ 0.002 mm | Δ 0.003 mm | Δ 0.004 mm | Δ 0.006 mm |

Important: Parallelism tolerance is critical for ensuring long-term performance and accuracy of the guideway system. Appropriate measuring tools should be used for verification during installation.