1.5.1 Stiffness Definition

Stiffness is a technical parameter that describes the relationship between external forces acting on an object and the object's elastic deformation.

For SCHNEEBERGER MONORAIL guideways, the overall stiffness of the guideway is influenced by the following factors:

- The guideway components themselves (guide rail, carriage, and rolling elements)

- The surrounding structure

- The connection between guideway and machine bed

- The connection method of the axis carriage

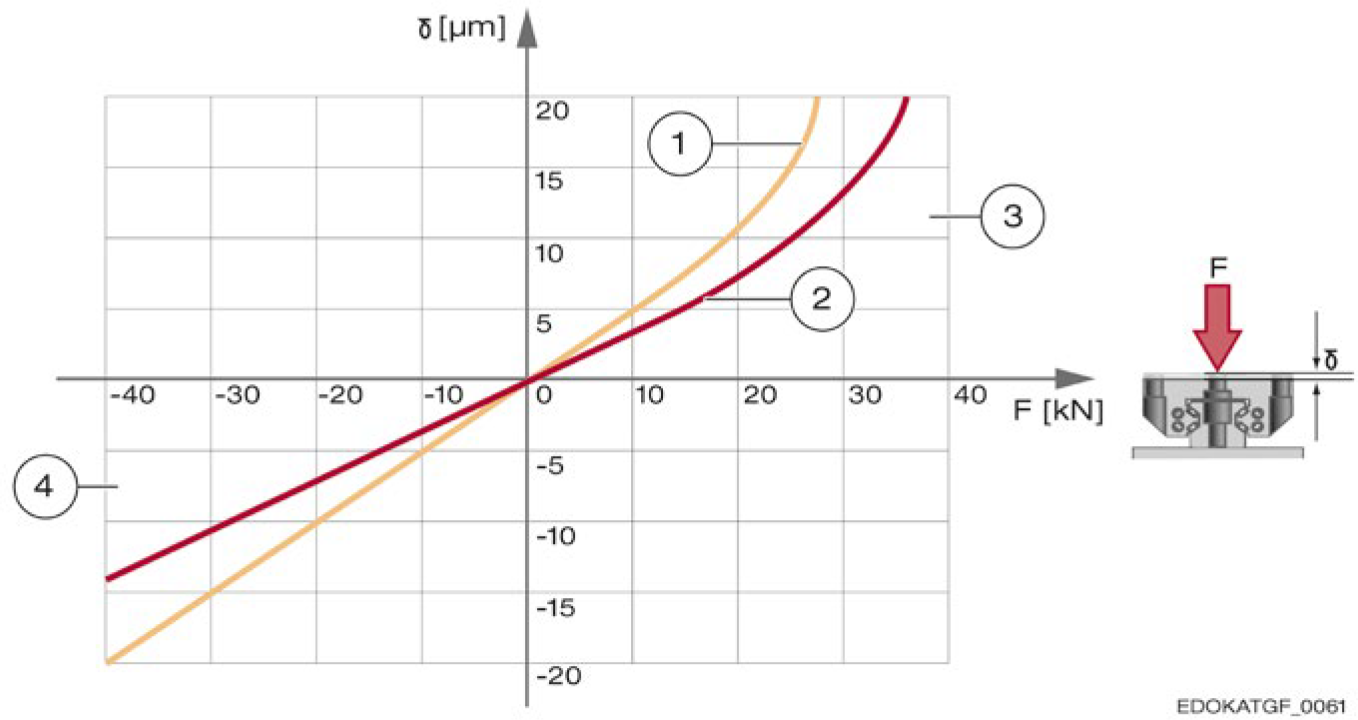

Stiffness is an important criterion for selecting SCHNEEBERGER MONORAIL guideways. In the SCHNEEBERGER MONORAIL and AMS product catalog, stiffness is provided in chart form, showing stiffness characteristics for the main force directions (tension and compression). The chart only considers the carriage/guide rail profile system itself.

Deformation δ (μm) is applied against the load F (kN) and results in compressive rigidity or tensile rigidity.

Legend:

δ = Deformation

F = Force

Tensile Rigidity Quadrant (3)

Positive force direction (F > 0) produces positive deformation (δ > 0), showing the guideway's deformation characteristics under tensile load.

Compressive Rigidity Quadrant (4)

Negative force direction (F < 0) produces negative deformation (δ < 0), showing the guideway's deformation characteristics under compressive load.

Stiffness Curve Characteristics

As can be seen from the chart, the stiffness curve exhibits non-linear (degressive) characteristics. This means that under smaller forces, deformation is relatively soft; as force increases, the system becomes stiffer. Long carriages (B and D types) have better stiffness performance than short carriages (A and C types) due to having more loaded rolling elements.

Design Tip

During the design phase, required stiffness should be evaluated based on actual load conditions. SCHNEEBERGER provides stiffness charts for each product series in the product catalog, which can be used to calculate expected deformation under specific loads.