10.2 MINISCALE PLUS Technical Information

10.2.1 MINISCALE PLUS Performance Parameters

| Maximum acceleration | 300 m/s² |

|---|---|

| Maximum speed | 5 m/s analogue, 3.2 m/s digital |

| Preload class | V1 preload 0 to 0.03 C (C = dynamic load capacity) |

| Accuracy class | G1 |

| Material |

|

| Application range |

|

| Resolution | TTL output 0.1 µm (3) (optional: 1 µm / 10 µm) |

| Accuracy (2) | 1000 mm ±5 µm (4) |

| Repeatability (2) |

Unidirectional ±0.1 µm Bidirectional ±0.2 µm (at 0.1 µm resolution) |

| Measuring scale |

Pitch 100 µm Maximum length 1000 mm Coefficient of expansion 11.7 × 10-6K-1 |

| Supply voltage | 5 V DC ±5 % |

| Current consumption (typical) | 60 mA (analogue) / 90 mA (digital) |

| Output signal |

Analogue: 1 Vpp (at 120 Ω) Digital: TTL compliant with RS 422 standard |

| Signal format | Differential sin/cos analogue signals with reference pulse or digital incremental signals with reference pulse |

(1) Standard lubrication covers a temperature range from -20 °C to +80 °C. Lubricants for other temperatures are available from SCHNEEBERGER on request.

(2) Values apply at a room temperature of 20 °C (68 °F).

(3) Note the high signal frequency at high resolution and high speed.

(4) ±5 µm = sum of individual errors.

10.2.2 Dimension Tables, Load Capacities and Torque Loads for Standard MINISCALE PLUS

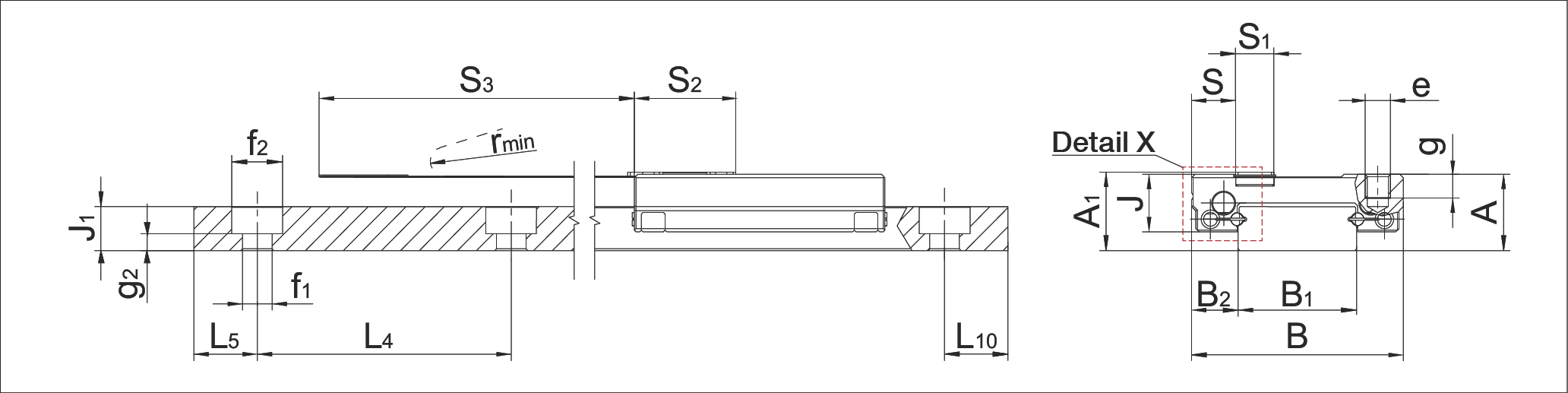

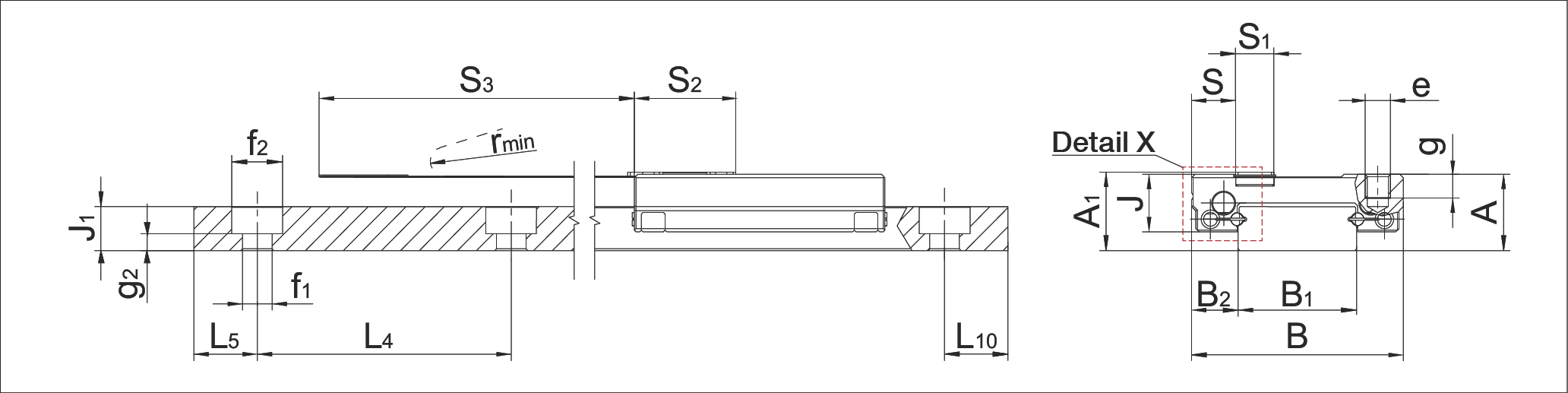

MINISCALE PLUS Standard Dimensional Drawing

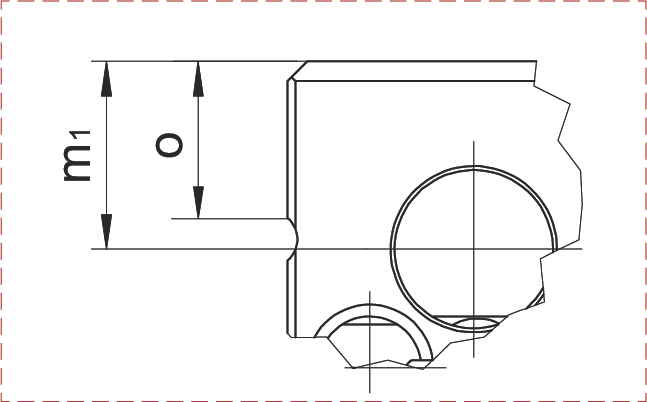

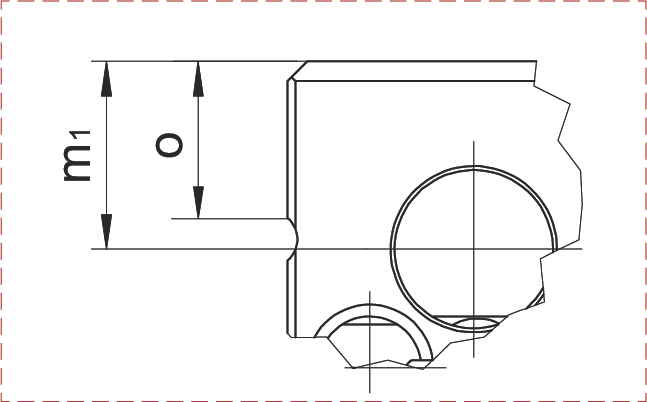

Detail X - Carriage Cross-section Dimensions (m1 and o)

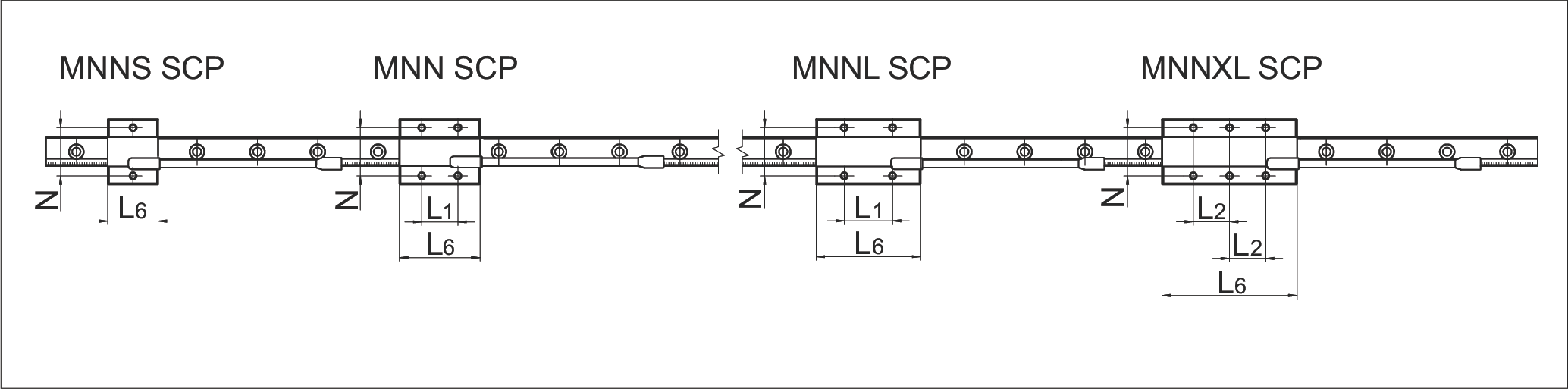

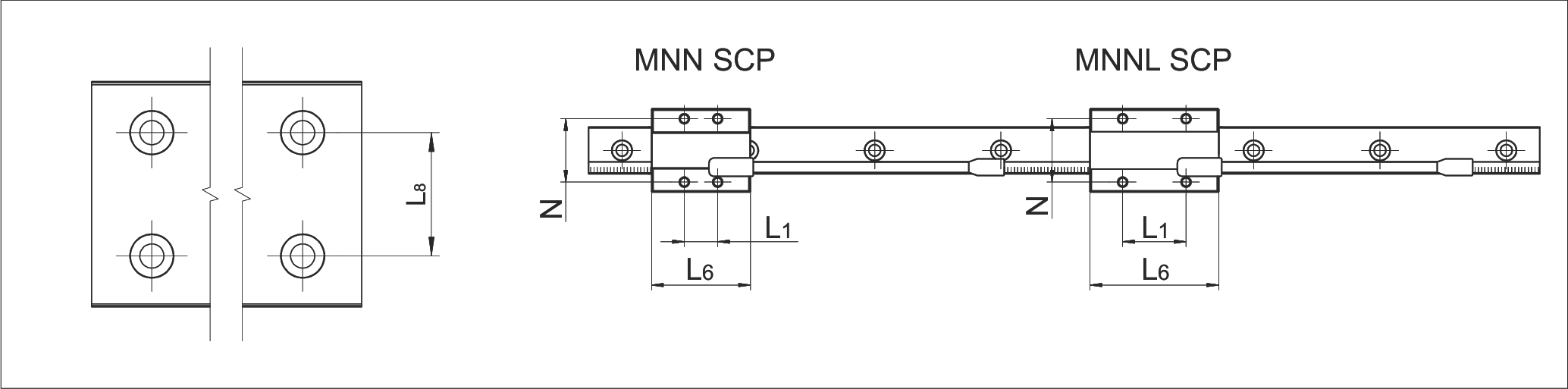

Carriage Types - MNNS SCP, MNN SCP, MNNL SCP, MNNXL SCP (4 types)

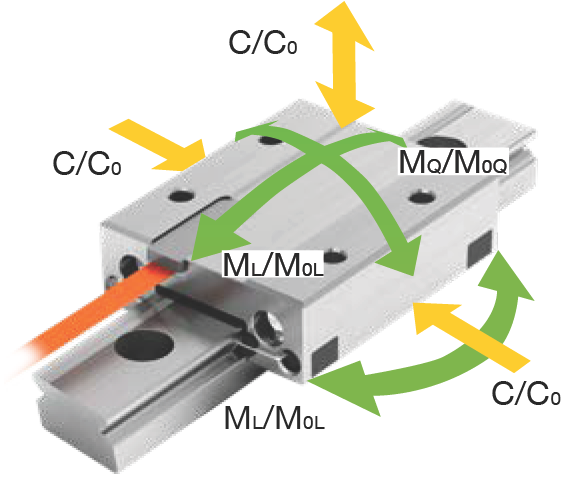

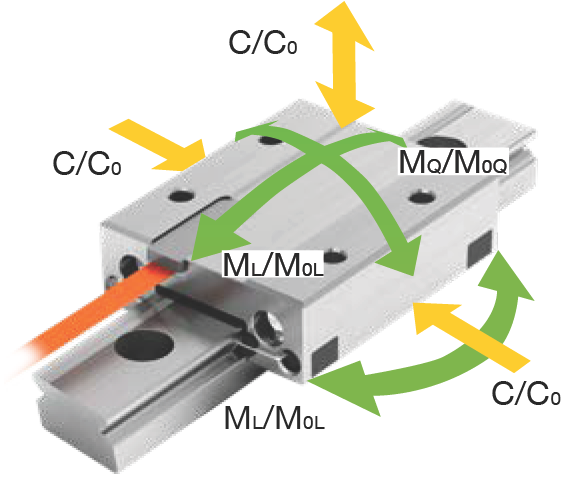

Load and Torque Load Directions (C/C₀, ML/M₀L, Ma/M₀a)

Standard size 7 and 9

| Name | Standard size 7 | Standard size 9 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Guideway | MNNS SCP | MNN SCP | MNNL SCP | MNNXL SCP | Guideway | MNNS SCP | MNN SCP | MNNL SCP | MNNXL SCP | ||

| Dimensions (mm) | A | - | 7 | 7 | 7 | 7 | - | 9 | 9 | 9 | 9 |

| A1 | - | 8 | 8 | 8 | 8 | - | - | - | - | - | |

| B | - | 17 | 17 | 17 | 17 | - | 20 | 20 | 20 | 20 | |

| B1 | 7 | - | - | - | - | 9 | - | - | - | - | |

| B2 | - | 5 | 5 | 5 | 5 | - | 5.5 | 5.5 | 5.5 | 5.5 | |

| J | - | 4.6 | 4.6 | 4.6 | 4.6 | - | 6 | 6 | 6 | 6 | |

| J1 | 3.6 | - | - | - | - | 4.6 | - | - | - | - | |

| L1 | - | - | 10 | 13 | 20 | - | - | 12 | 17 | 27 | |

| L2 | - | - | - | - | 10 | - | - | - | - | 12 | |

| L4 | 20 | - | - | - | - | 20 | - | - | - | - | |

| L5/L10 | 7.5 | - | - | - | - | 7.5 | - | - | - | - | |

| L6 | - | 12.9 | 20.9 | 30.9 | 40.4 | - | 18.7 | 29.2 | 40.7 | 53.2 | |

| N | - | 12 | 12 | 12 | 12 | - | 14 | 14 | 14 | 14 | |

| e | - | M2 | M2 | M2 | M2 | - | M2.5 | M2.5 | M2.5 | M2.5 | |

| f1 | 2.2 | - | - | - | - | 3 | - | - | - | - | |

| f2 | 4 | - | - | - | - | 5 | - | - | - | - | |

| g | - | 2 | 2 | 2 | 2 | - | 2.5 | 2.5 | 2.5 | 2.5 | |

| g2 | 1.8 | - | - | - | - | 2 | - | - | - | - | |

| m1 | - | 2.4 | 2.4 | 2.4 | 2.4 | - | 2.75 | 2.75 | 2.75 | 2.75 | |

| o | - | 1.5 | 1.5 | 1.5 | 1.5 | - | 2.2 | 2.2 | 2.2 | 2.2 | |

| s | - | 4 | 4 | 4 | 4 | - | 4.8 | 4.8 | 4.8 | 4.8 | |

| s1 | - | 5.5 | 5.5 | 5.5 | 5.5 | - | 5.5 | 5.5 | 5.5 | 5.5 | |

| s2 | - | 13.5 | 13.5 | 13.5 | 13.5 | - | 13.5 | 13.5 | 13.5 | 13.5 | |

| s3 | - | 75 | 75 | 75 | 75 | - | 75 | 75 | 75 | 75 | |

| rmin | - | 2 | 2 | 2 | 2 | - | 2 | 2 | 2 | 2 | |

| Load capacity (N) | C0 | - | 420 | 840 | 1260 | 1680 | - | 795 | 1590 | 2385 | 3180 |

| C | - | 410 | 640 | 840 | 1040 | - | 670 | 1040 | 1690 | 2140 | |

| Torque (Nm) | M0Q | - | 1.6 | 3.2 | 4.8 | 6.4 | - | 3.8 | 7.5 | 11.3 | 15 |

| M0L | - | 0.8 | 2.2 | 4.5 | 8.8 | - | 1.5 | 6 | 11.3 | 20.2 | |

| MQ | - | 1.5 | 2.4 | 3.2 | 4 | - | 3.2 | 4.9 | 8 | 10.1 | |

| ML | - | 0.7 | 1.7 | 3 | 5.5 | - | 1.3 | 4.6 | 7.9 | 12.7 | |

| Weights guideway (g/m), carriage (g) | 133 | 4 | 5 | 8 | 11 | 216 | 9 | 13 | 18 | 23 | |

The table includes size 9 data. Additional sizes are shown below.

Standard size 12 and 15

| Name | Standard size 12 | Standard size 15 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Guideway | MNNS SCP | MNN SCP | MNNL SCP | MNNXL SCP | Guideway | MNNS SCP | MNN SCP | MNNL SCP | MNNXL SCP | ||

| Dimensions (mm) | A | - | 13 | 13 | 13 | 13 | - | 16 | 16 | 16 | 16 |

| A1 | - | - | - | - | - | - | - | - | - | - | |

| B | - | 27 | 27 | 27 | 27 | - | 32 | 32 | 32 | 32 | |

| B1 | 12 | - | - | - | - | 15 | - | - | - | - | |

| B2 | - | 7.5 | 7.5 | 7.5 | 7.5 | - | 8.5 | 8.5 | 8.5 | 8.5 | |

| J | - | 10 | 10 | 10 | 10 | - | 12 | 12 | 12 | 12 | |

| J1 | 7.5 | - | - | - | - | 10 | - | - | - | - | |

| L1 | - | - | 15 | 20 | 30 | - | - | 20 | 25 | 40 | |

| L2 | - | - | - | - | 15 | - | - | - | - | 20 | |

| L4 | 25 | - | - | - | - | 30 | - | - | - | - | |

| L5/L10 | 10 | - | - | - | - | 12.5 | - | - | - | - | |

| L6 | - | 20.9 | 33.4 | 43.4 | 55.9 | - | 28.7 | 40.7 | 55.7 | 70.7 | |

| N | - | 20 | 20 | 20 | 20 | - | 25 | 25 | 25 | 25 | |

| e | - | M3 | M3 | M3 | M3 | - | M3 | M3 | M3 | M3 | |

| f1 | 3.5 | - | - | - | - | 4.5 | - | - | - | - | |

| f2 | 6 | - | - | - | - | 8 | - | - | - | - | |

| g | - | 3.5 | 3.5 | 3.5 | 3.5 | - | 4 | 4 | 4 | 4 | |

| g2 | 3 | - | - | - | - | 3.5 | - | - | - | - | |

| m1 | - | 4.75 | 4.75 | 4.75 | 4.75 | - | 5.55 | 5.55 | 5.55 | 5.55 | |

| o | - | 3.9 | 3.9 | 3.9 | 3.9 | - | 4.9 | 4.9 | 4.9 | 4.9 | |

| s | - | 6.7 | 6.7 | 6.7 | 6.7 | - | 8.3 | 8.3 | 8.3 | 8.3 | |

| s1 | - | 5.5 | 5.5 | 5.5 | 5.5 | - | 5.5 | 5.5 | 5.5 | 5.5 | |

| s2 | - | 13.5 | 13.5 | 13.5 | 13.5 | - | 13.5 | 13.5 | 13.5 | 13.5 | |

| s3 | - | 75 | 75 | 75 | 75 | - | 75 | 75 | 75 | 75 | |

| rmin | - | 2 | 2 | 2 | 2 | - | 2 | 2 | 2 | 2 | |

| Load capacity (N) | C0 | - | 1735 | 3900 | 5630 | 7800 | - | 3420 | 5620 | 8740 | 11855 |

| C | - | 1420 | 2510 | 3240 | 4070 | - | 2535 | 3680 | 5000 | 6200 | |

| Torque (Nm) | M0Q | - | 10.6 | 23.8 | 34.4 | 47.6 | - | 26.7 | 42.7 | 66.4 | 90.1 |

| M0L | - | 3.6 | 16.3 | 32.9 | 61.8 | - | 11.4 | 28.1 | 65.5 | 118.6 | |

| MQ | - | 8.7 | 15.3 | 19.8 | 24.8 | - | 19.5 | 27.9 | 38.1 | 47.1 | |

| ML | - | 3 | 10.4 | 18.9 | 32.2 | - | 9.3 | 18.4 | 37.6 | 62 | |

| Weights guideway (g/m), carriage (g) | 598 | 29 | 47 | 63 | 81 | 1016 | 81 | 114 | 130 | 146 | |

10.2.3 Dimension Tables, Load Capacities and Torque Loads for Wide MINISCALE PLUS

MINISCALE PLUS Wide Dimensional Drawing

Detail X - Carriage Cross-section Dimensions (m1 and o)

Carriage Types - MNN SCP, MNNL SCP (Wide size only offers 2 types)

Load and Torque Load Directions (C/C₀, ML/M₀L, Ma/M₀a)

Wide size 14 and 18

Note: Wide size only offers 2 carriage types (MNN, MNNL).

| Name | Wide size 14 | Wide size 18 | |||||

|---|---|---|---|---|---|---|---|

| Guideway | MNN SCP | MNNL SCP | Guideway | MNN SCP | MNNL SCP | ||

| Dimensions (mm) | A | - | 9 | - | - | 12 | - |

| A1 | - | 10 | - | - | - | - | |

| B | - | 25 | - | - | 30 | - | |

| B1 | 14 | - | - | 18 | - | - | |

| B2 | - | 5.5 | - | - | 6 | - | |

| J | - | 6.8 | - | - | 8.5 | - | |

| J1 | 5.2 | - | - | 7 | - | - | |

| L1 | - | 10 | 19 | - | 12 | 24 | |

| L2 | - | - | - | - | - | - | |

| L4 | 30 | - | - | 30 | - | - | |

| L5/L10 | 10 | - | - | 10 | - | - | |

| L6 | - | 29.6 | 38.6 | - | 37 | 47 | |

| L7 | - | - | - | - | - | - | |

| N | - | 19 | - | - | 21 | - | |

| e | - | M3 | - | - | M3 | - | |

| f1 | 3.5 | - | - | 3.5 | - | - | |

| f2 | 6 | - | - | 6 | - | - | |

| g | - | 2.8 | - | - | 3 | - | |

| g2 | 2 | - | - | 2.5 | - | - | |

| m1 | - | 3.3 | - | - | 4.3 | - | |

| o | - | 2.2 | - | - | 3.1 | - | |

| s | - | 5.2 | - | - | 5.8 | - | |

| s1 | - | 5.5 | - | - | 5.5 | - | |

| s2 | - | 13.5 | - | - | 13.5 | - | |

| s3 | - | 75 | - | - | 75 | - | |

| rmin | - | 2 | - | - | 2 | - | |

| Load capacity (N) | C0 | - | 2340 | 3275 | - | 3880 | 5270 |

| C | - | 1230 | 1550 | - | 2140 | 2645 | |

| Torque (Nm) | M0Q | - | 16.6 | 23.3 | - | 35.5 | 48.2 |

| M0L | - | 9.3 | 18 | - | 19.4 | 35.1 | |

| MQ | - | 8.7 | 11 | - | 19.6 | 24.2 | |

| ML | - | 4.9 | 8.5 | - | 10.7 | 17.6 | |

| Weights guideway (g/m), carriage (g) | 518 | 25 | 33 | 915 | 47 | 60 | |

Wide size 24 and 42

| Name | Wide size 24 | Wide size 42 | |||||

|---|---|---|---|---|---|---|---|

| Guideway | MNN SCP | MNNL SCP | Guideway | MNN SCP | MNNL SCP | ||

| Dimensions (mm) | A | - | 14 | - | - | 16 | - |

| A1 | - | - | - | - | - | - | |

| B | - | 40 | - | - | 60 | - | |

| B1 | 24 | - | - | 42 | - | - | |

| B2 | - | 8 | - | - | 9 | - | |

| J | - | 10 | - | - | 12 | - | |

| J1 | 8.5 | - | - | 9.5 | - | - | |

| L1 | - | 15 | 28 | - | 20 | 35 | |

| L2 | - | - | - | - | - | - | |

| L4 | 40 | - | - | 40 | - | - | |

| L5/L10 | 15 | - | - | 15 | - | - | |

| L6 | - | 43.4 | 55.9 | - | 52.7 | 70.7 | |

| L7 | - | - | - | 23 | - | - | |

| N | - | 28 | - | - | 45 | - | |

| e | - | M3 | - | - | M4 | - | |

| f1 | 4.5 | - | - | 4.5 | - | - | |

| f2 | 8 | - | - | 8 | - | - | |

| g | - | 3.5 | - | - | 4.5 | - | |

| g2 | 4 | - | - | 5 | - | - | |

| m1 | - | 4.75 | - | - | 5.5 | - | |

| o | - | 3.9 | - | - | 4.9 | - | |

| s | - | 7.8 | - | - | 8.8 | - | |

| s1 | - | 5.5 | - | - | 5.5 | - | |

| s2 | - | 13.5 | - | - | 13.5 | - | |

| s3 | - | 75 | - | - | 75 | - | |

| rmin | - | 2 | - | - | 2 | - | |

| Load capacity (N) | C0 | - | 5630 | 7800 | - | 8110 | 11855 |

| C | - | 3240 | 4070 | - | 4750 | 6200 | |

| Torque (Nm) | M0Q | - | 68.2 | 94.4 | - | 171.2 | 250.2 |

| M0L | - | 32.9 | 61.8 | - | 56.8 | 118.6 | |

| MQ | - | 39.2 | 49.3 | - | 100.3 | 130.8 | |

| ML | - | 18.9 | 32.2 | - | 33.3 | 62 | |

| Weights guideway (g/m), carriage (g) | 1476 | 84 | 109 | 2828 | 169 | 231 | |

MINISCALE PLUS integrates a linear guideway and position measuring system, providing a complete motion control solution.

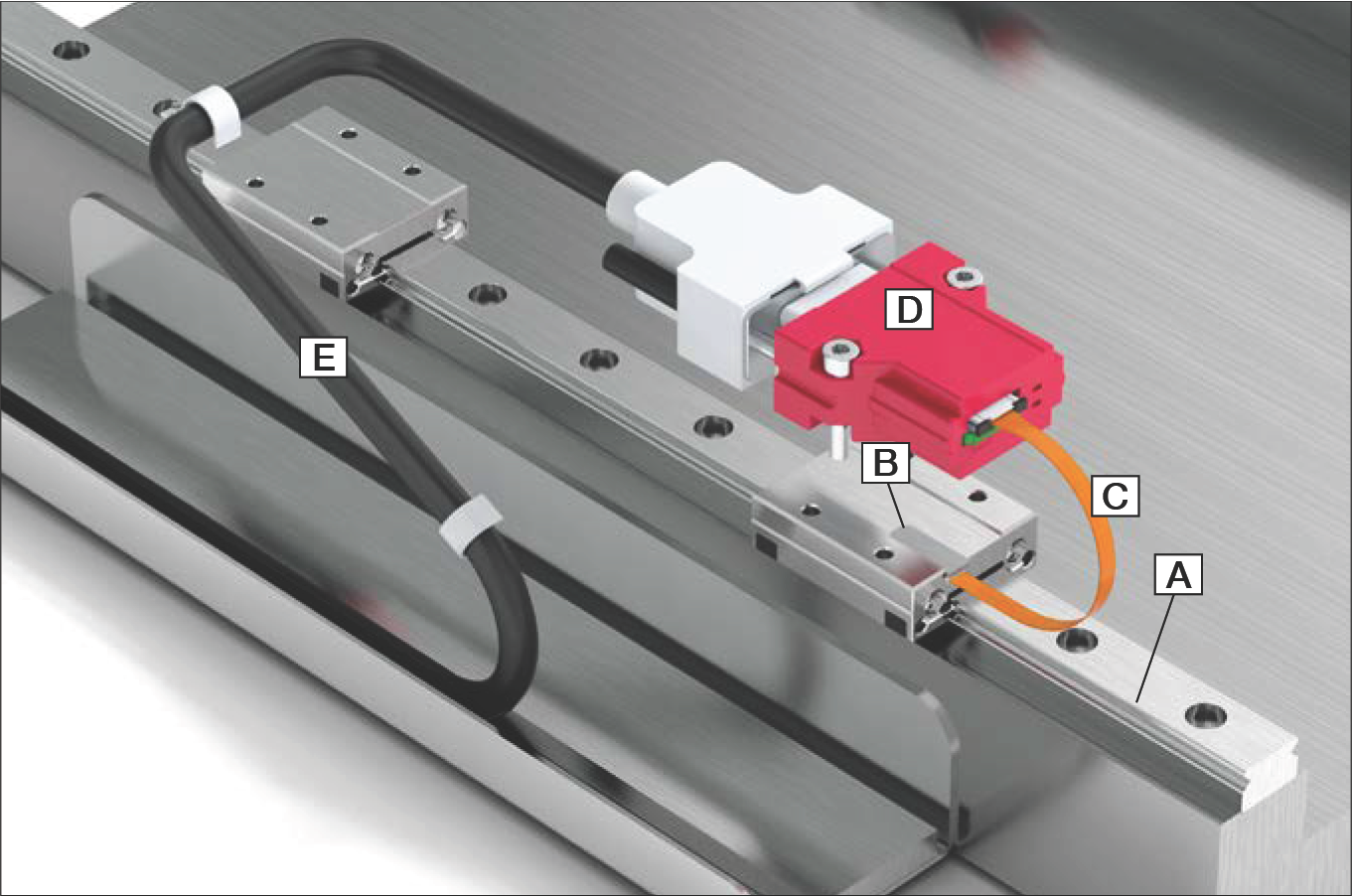

10.2.4 MINISCALE PLUS Components and Operating Principle

MINISCALE PLUS is an optical incremental measuring system consisting of a MINIRAIL guideway system and the following additional components:

- A Measuring scale on the guideway

- B Optical sensor on the carriage

- C Flexible sensor printed circuit (must not be subjected to dynamic loads)

- D Interface module

Control cable E with D-Sub 9 connector must be provided by the customer; flexible cables should be used if necessary.

Interface modules are available in various design types. These are described in detail in the "Interface Modules" section.

Using a flat flex cable (FFC) between the flexible sensor printed circuit and the interface module allows flexible positioning of the interface module. FFC cables are suitable for dynamic loads. (For details, see Section 10.2.8)

Axis with MINIRAIL, MINISCALE PLUS and interface module

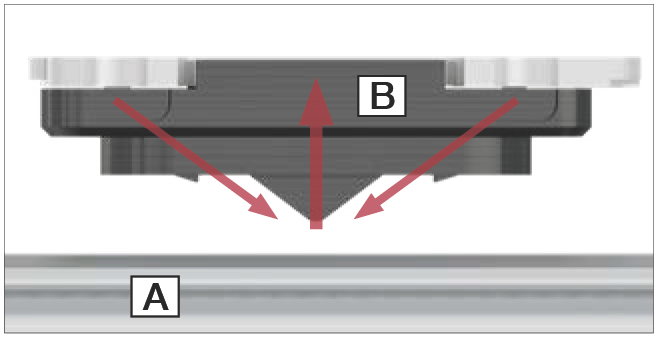

Sensor Principle

A: Measuring scale on guideway | B: Sensor in carriage

Measuring Scale and Optical Sensor

The high-precision measuring scale is part of the hardened guideway surface with a scale increment of 100 µm. Two LEDs in the sensor illuminate the measuring scale. Due to illumination of different structural areas, bright and dark fields are formed. These optical signals are detected by the sensor and converted into electrical signals. The raw signals from the sensor are processed by the interface module.

The illumination level of the LEDs is actively controlled. This compensates for ageing effects in the system and for impurities on the measuring scale.

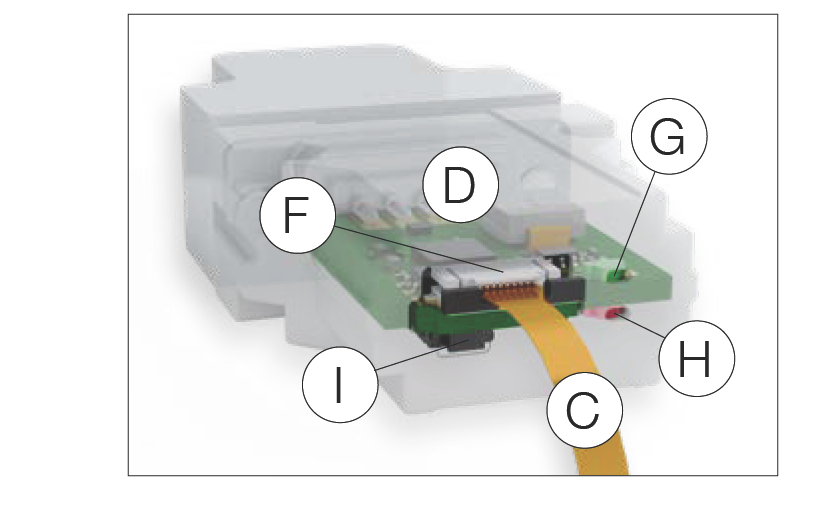

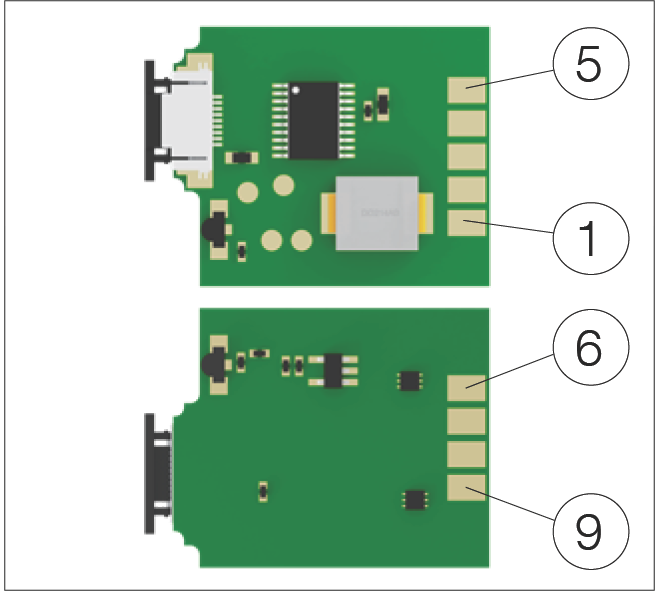

MINISCALE PLUS Sensor Components

Interface Module Components

Interface Module

The raw signals are processed by the interface module and converted into standard output signals. Analogue or digital interface modules are available.

Ensure that the ZIF connector F is easily accessible and that the LED indicators on the interface module (G and H) are clearly visible. Unlike the analogue interface, the digital interface includes a compensation key I, which must also be easily accessible.

- C Flexible sensor printed circuit

- D Electronics (various design types available)

- F ZIF connector

- G Green LED (operating voltage indicator)

- H Red LED (error indicator)

- I Compensation key (digital interface module only)

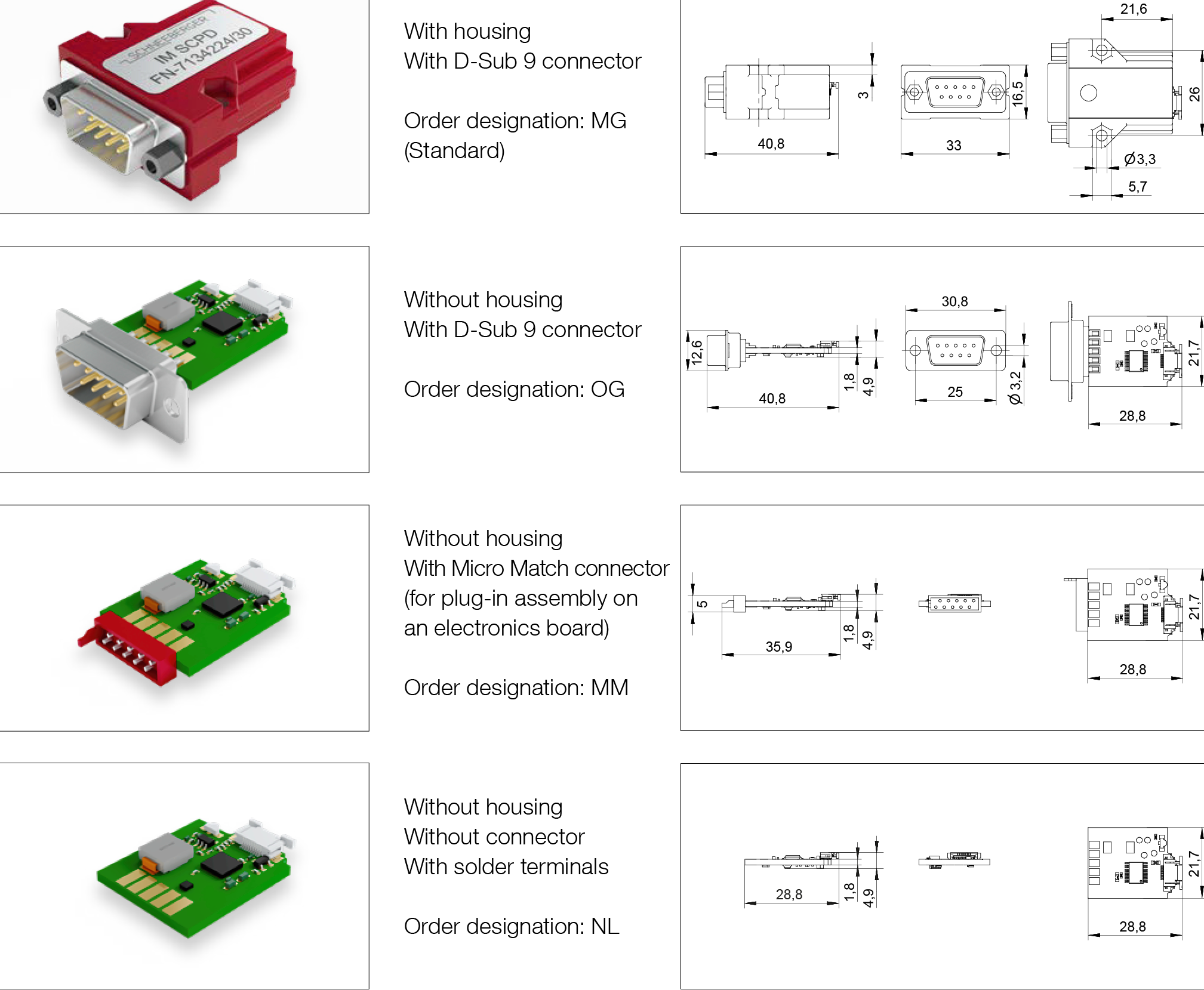

Interface modules are available in the following design types:

Interface Module Design Types

For customers with electronics expertise, it is also possible, after consultation with SCHNEEBERGER, to assemble the digital interface module themselves and integrate it into their own electronics system.

Order code: KI

10.2.5 Signal Processing

For more information on signal processing, please visit our website download area: www.schneeberger.com

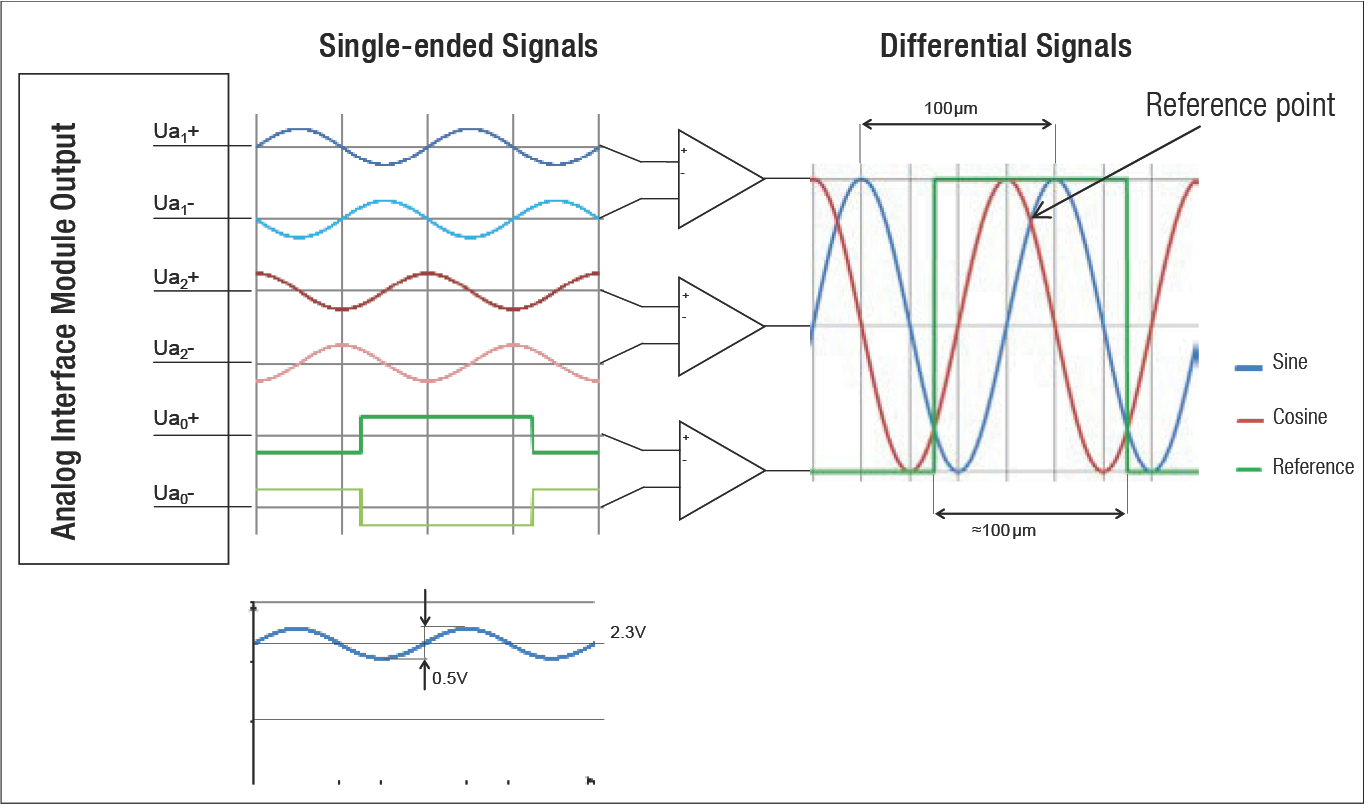

Analogue Output Format

Differential sin/cos analogue signals with reference pulse 1 Vpp (at 120 Ω).

The incremental signals sine and cosine are 90° apart and are related to the marks on the encoder scale. One electrical signal period (360°) corresponds exactly to a scale increment of 100 µm.

The reference pulse always electronically marks the same section of the sine and cosine signal paths. Therefore, the intersection of both signals within the reference pulse marks a precisely defined position on the measuring scale.

The sine signal either lags or leads the cosine signal, depending on the direction of travel.

Differential signals output from analogue interface module

Single-ended signals | Differential signals (Sine, Cosine, Reference)

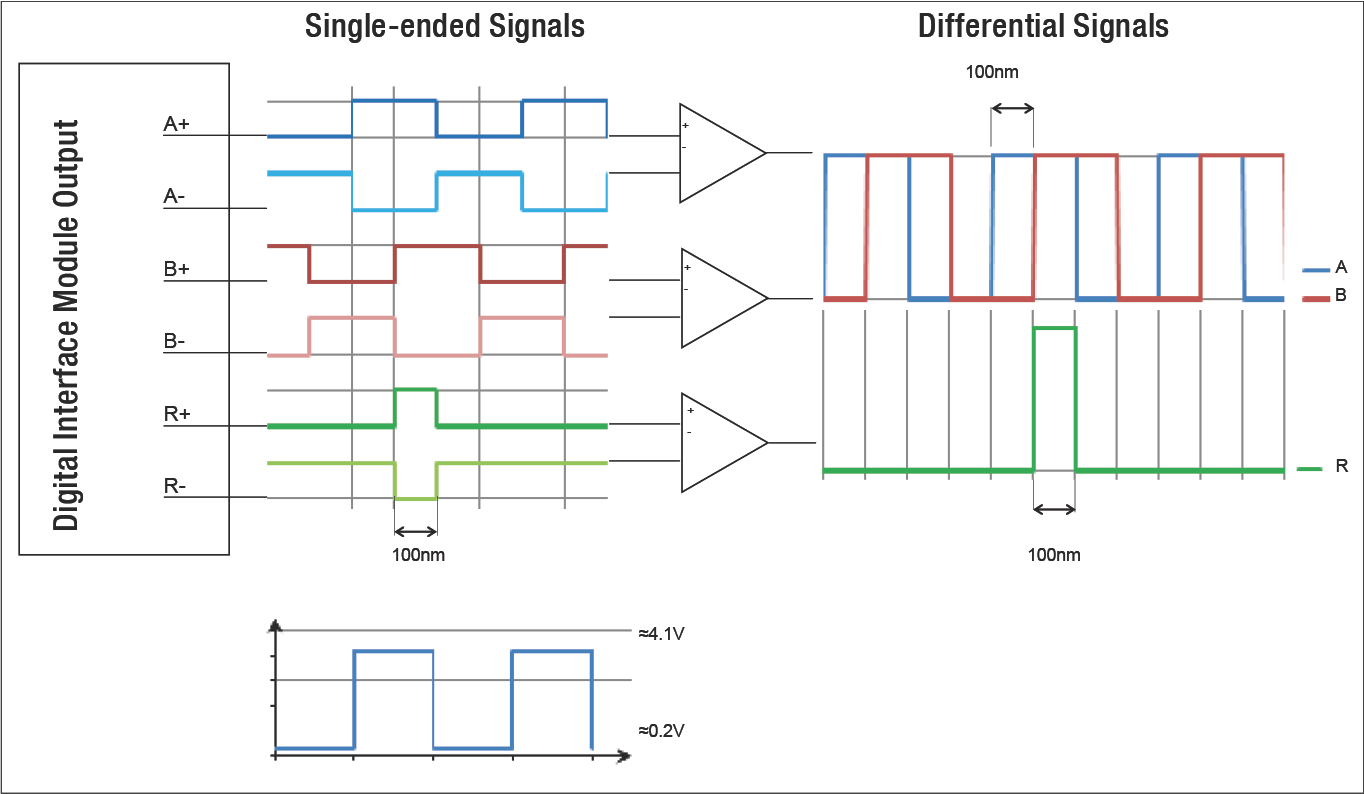

Digital Output Format

Differential interpolated digital signals with reference pulse (A, B, R) TTL signals (RS422).

The digital interface module both processes the raw signals and interpolates the processed analogue signals. Interpolation achieves a resolution of 100 nm.

The digital signal waveform consists of A and B signals. The distance between two edges of signals A and B corresponds exactly to 100 nm. Therefore, the 100 µm increment of the encoder scale is divided into 1000 segments of 100 nm through interpolation. Signal A either lags or leads signal B, depending on the direction of travel.

The width of the reference pulse is the same as the distance between two signal edges of signals A and B (100 nm).

The edges of the incremental signals and reference signal are synchronised.

Differential signals output from digital interface module

Single-ended signals | Differential signals (A, B, R)

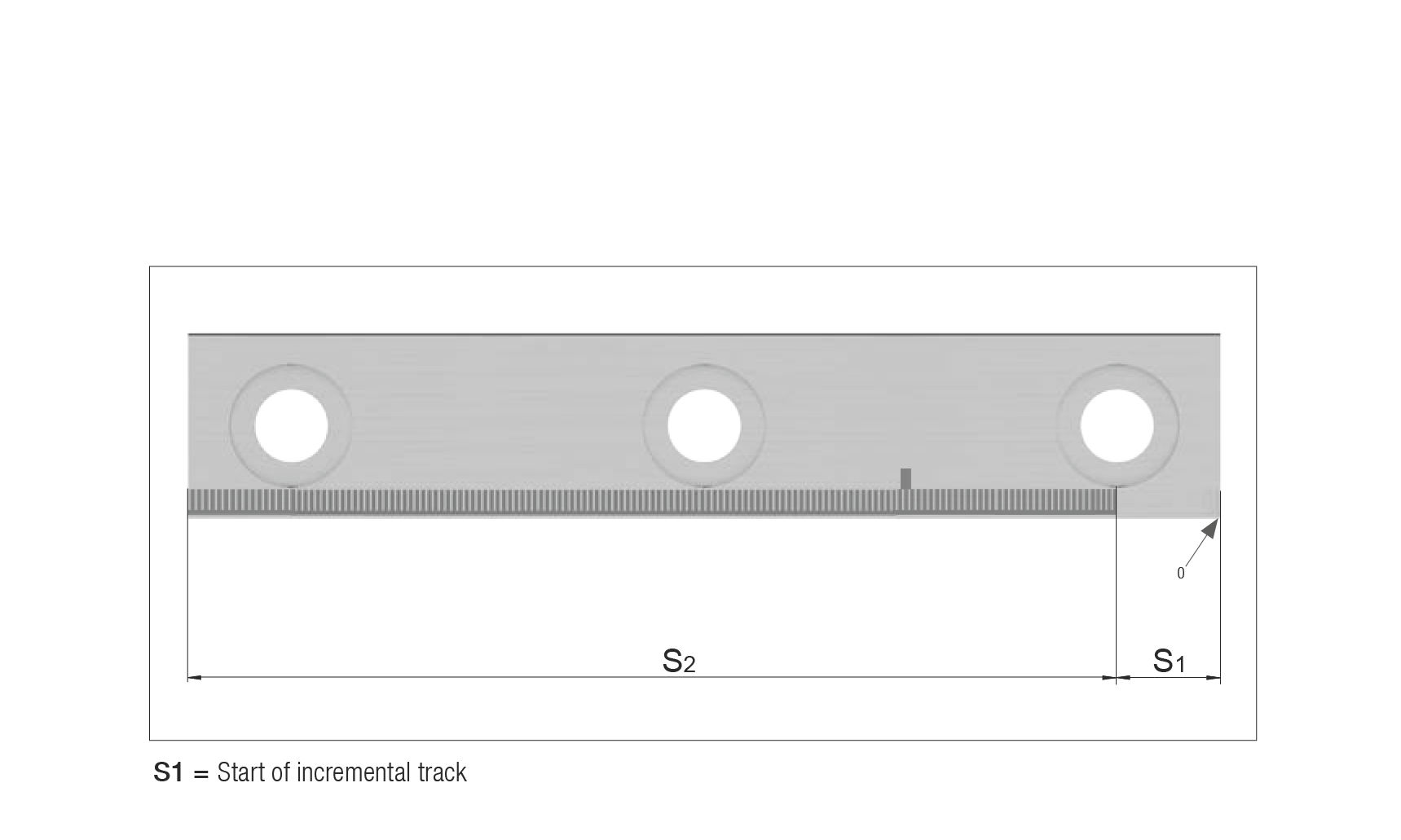

10.2.6 Incremental Track

In the standard version, the incremental track extends over the entire guideway length. Position and length can be adjusted according to customer requirements.

Incremental track position and length

S1 = Incremental track start | S2 = Incremental track length

S1 = Incremental track start

S2 = Incremental track length

Limitations

- For analogue MINISCALE PLUS guideways, S2 must be at least 30 mm.

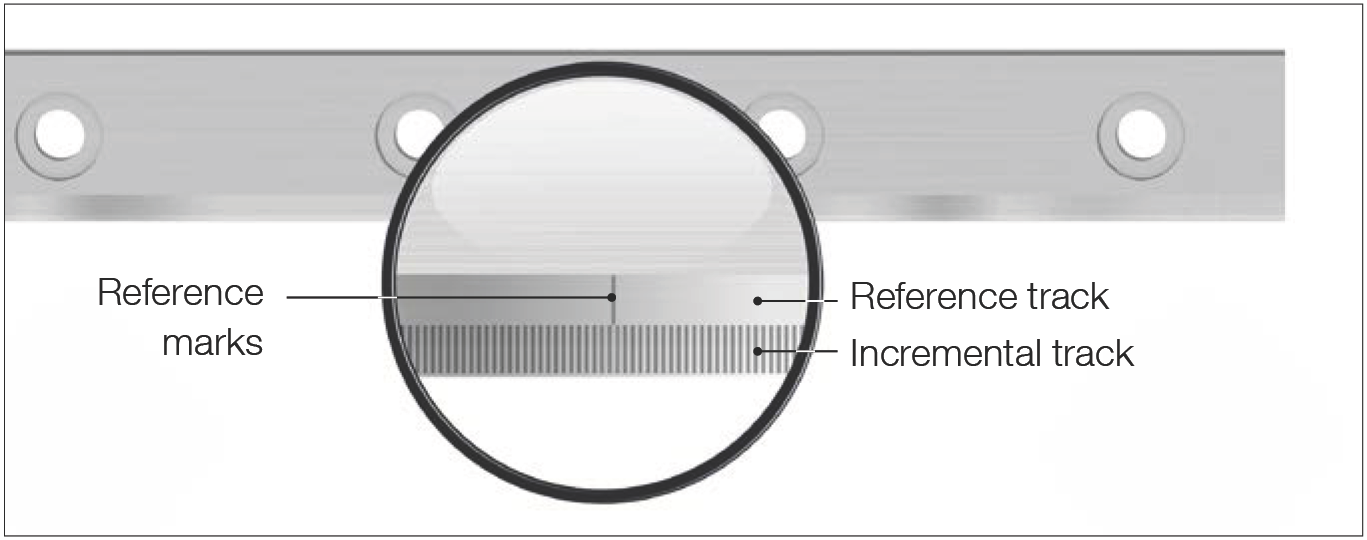

Reference Marks

Incremental measuring systems cannot determine the exact position at power-up. Therefore, a reference track is added next to the incremental track. One or more reference points can be marked on the reference track.

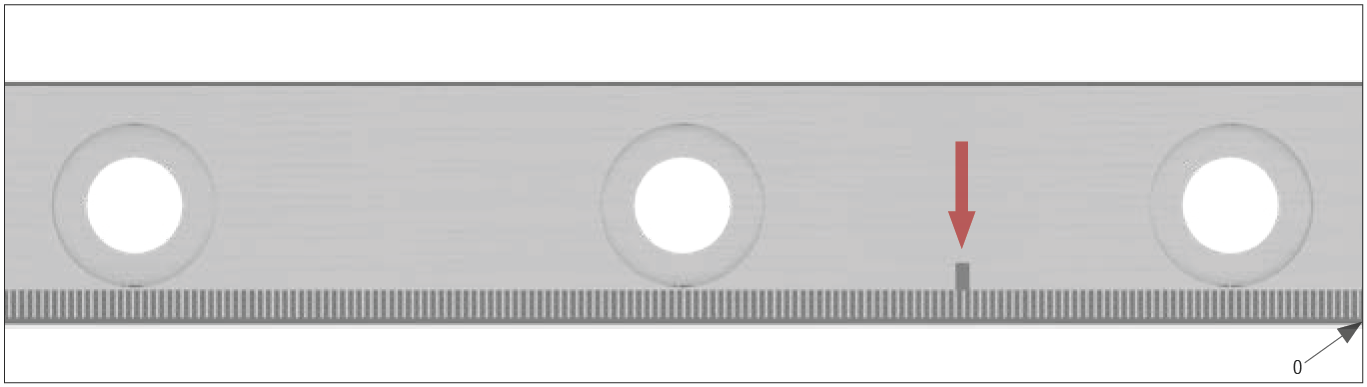

MINISCALE PLUS guideway with measuring scale

Reference track | Incremental track | Reference marks

Standard Version

The standard reference position for all sizes is defined as follows:

- Reference positioning at the centre of the first and second fixing holes

Standard position of reference marks for all sizes

Special Versions

Any number of reference marks can be selected at any position on the reference track. Reference marks must be synchronised with the measuring scale. This specifically means that reference marks can only be placed in multiples of 0.1 mm, as the scale pitch is 0.1 mm. A minimum distance of at least 1.5 mm should be maintained between reference marks. Additionally, the distance between the end of the incremental track and a reference mark must be at least 2 mm.

Limitations

- For sizes 7 and 9, the mounting holes on the guideway are located on the reference track. Therefore, for these two sizes, reference marks must be located between the mounting holes.

- When specifying reference marks, ensure that the carriage sensor can see them.

10.2.7 Analogue (1VSS) and Digital (TTL) Interface Module Pin Connections

MINISCALE PLUS offers 9-pin D-Sub male connectors or solder terminals as interface connection options.

D-Sub 9 connector pin assignment on interface module

Interface module solder terminal connection

9-pin D-Sub Male Connector or Solder Terminals:

| Pin | Analogue Signal | Digital Signal | Description |

|---|---|---|---|

| 1 | Ua1- | A - | Quadrature signal |

| 2 | 0V | 0V | Ground |

| 3 | Ua2- | B - | Quadrature signal |

| 4 | ERR NOT | ERR NOT | Error signal (low = error) |

| 5 | Ua0 - | R - | Reference signal |

| 6 | Ua1 + | A + | Quadrature signal |

| 7 | + 5V DC | + 5V DC | Supply voltage |

| 8 | Ua2 + | B + | Quadrature signal |

| 9 | Ua0 + | R + | Reference signal |

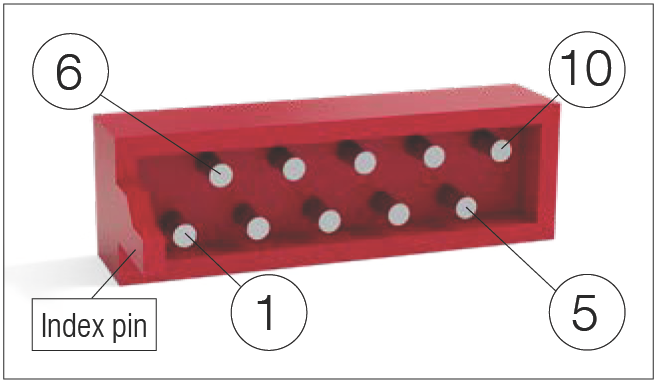

10-pin ZIF Connector:

ZIF connector pin configuration on interface module

| Pin | Analogue Signal | Digital Signal | Description |

|---|---|---|---|

| 1 | nc | nc | Not connected |

| 2 | Ua1 + | A + | Quadrature signal |

| 3 | + 5V DC | + 5V DC | Supply voltage |

| 4 | Ua2 + | B + | Quadrature signal |

| 5 | Ua0 + | R + | Reference signal |

| 6 | Ua1 - | A - | Quadrature signal |

| 7 | 0V | 0V | Ground |

| 8 | Ua2 - | B - | Quadrature signal |

| 9 | ERR NOT | ERR NOT | Error signal (low = error) |

| 10 | Ua0 - | R - | Reference signal |

Note: Different interface module design types may use different connector types. When ordering, please confirm the required connector type (D-Sub 9, ZIF, Micro Match, or solder terminals).

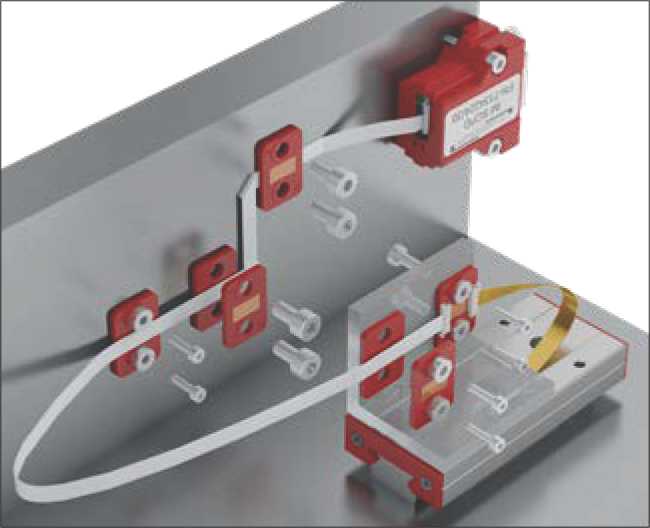

10.2.8 Extension Kit

When the interface module cannot be mounted directly on the sensor, an extension kit can be used. A flat flex cable (FFC) is used between the sensor printed circuit and the interface module.

FFC extension installation example

FFC cable with adapter

Advantages of the Extension Kit:

- By moving the interface module to a non-moving position, the mass of the moving system can be reduced.

- The shielded FFC cables included in the extension kit are also designed for dynamic loading. The recommended minimum bend radius is 10 mm. In contrast, the flexible sensor printed circuit can only be installed statically.

- FFC cables provide low push force. This can be an advantage in cases where cables in cable chains are too rigid.

- FFC cables can also be folded once during installation.

FFC cables are available in three lengths: 250 mm, 400 mm and 600 mm. Extension cables are supplied with adapter boards.

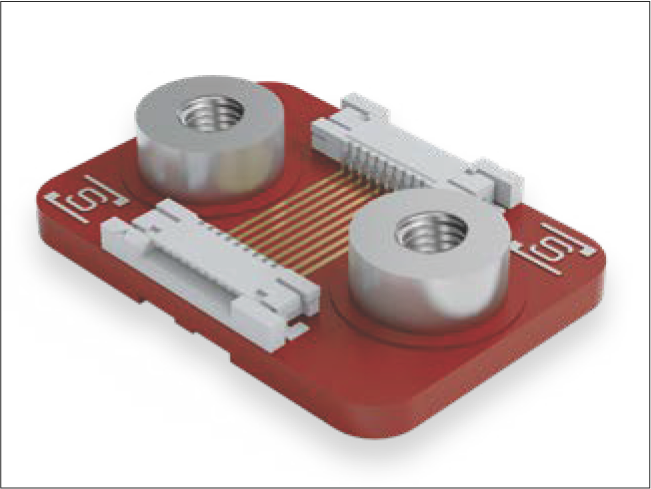

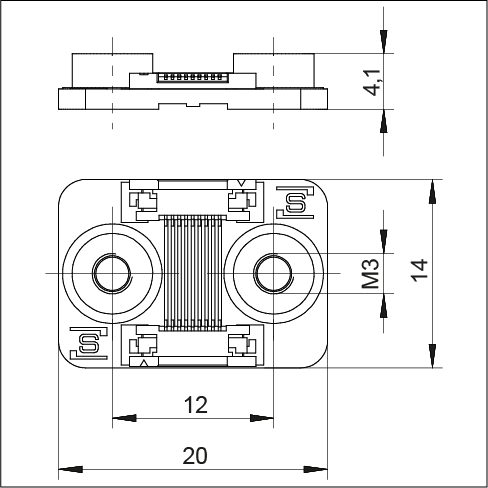

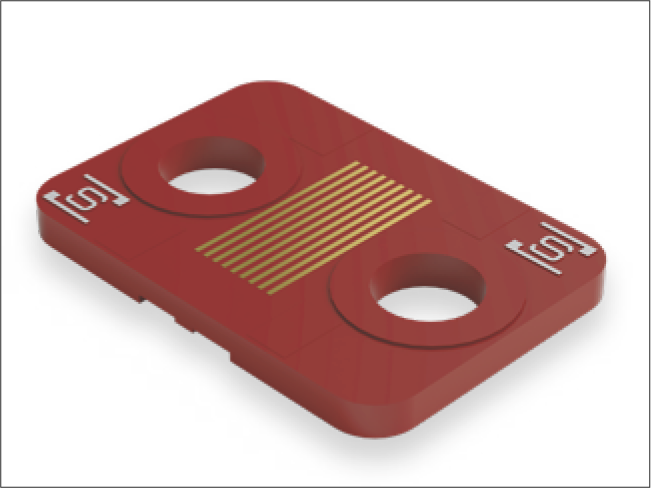

Adapter

Used for electrical connection between the sensor printed circuit and the extension cable. Two ZIF connectors on the adapter are available for this purpose.

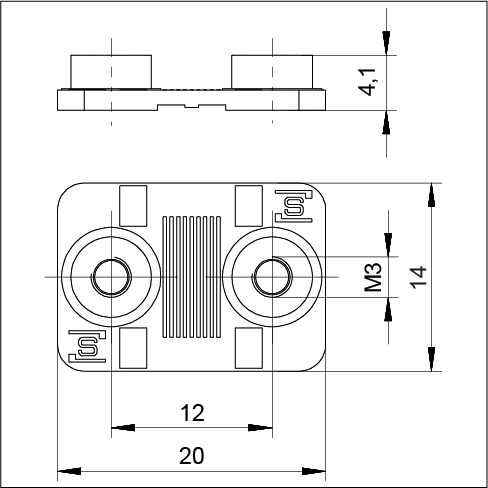

Adapter - 20×14 mm, M3 threaded holes

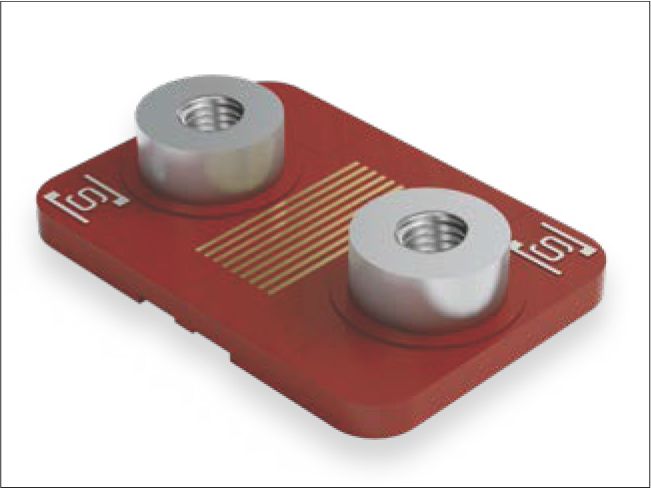

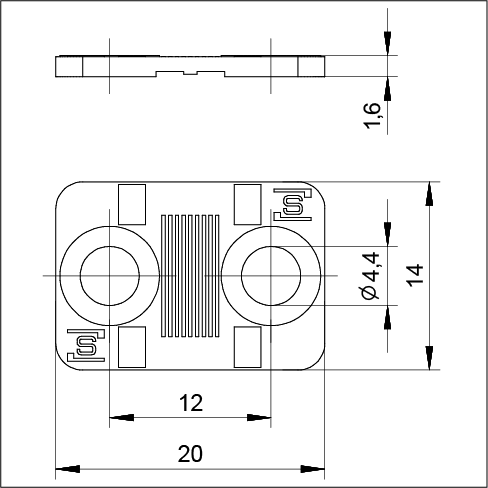

Clamp Plate

Can be used for strain relief or guiding the FFC cable. Two M3 spacer sleeves are mounted on the plate.

Clamp plate - can be used for strain relief or guiding the FFC cable

Base Plate

Can be used as a base or for clamping cables.

Base plate - can be used as a base or for clamping cables

10.2.9 Lubrication

Overview

Lubrication is a design element and must therefore be defined during the development phase of the machine or application. If lubrication is only specified after design and construction are complete, operational difficulties are likely to occur. Therefore, a carefully designed lubrication concept is a sign of advanced and thoughtful design.

Parameters to Consider When Selecting Lubricants:

| Operating conditions | Speed, acceleration, stroke, load, mounting orientation |

|---|---|

| External influences | Temperature, corrosive media or radiation, contamination, humidity, vacuum, cleanroom |

| Relubrication | Time period, quantity, compatibility |

| Compatibility | Compatibility with other lubricants, with corrosion protection, with integrated materials (e.g. plastics) |

Important: Proper lubrication is essential for long-term reliable operation of MINISCALE PLUS. Please select a suitable lubricant according to your specific application conditions and follow the recommended relubrication intervals.