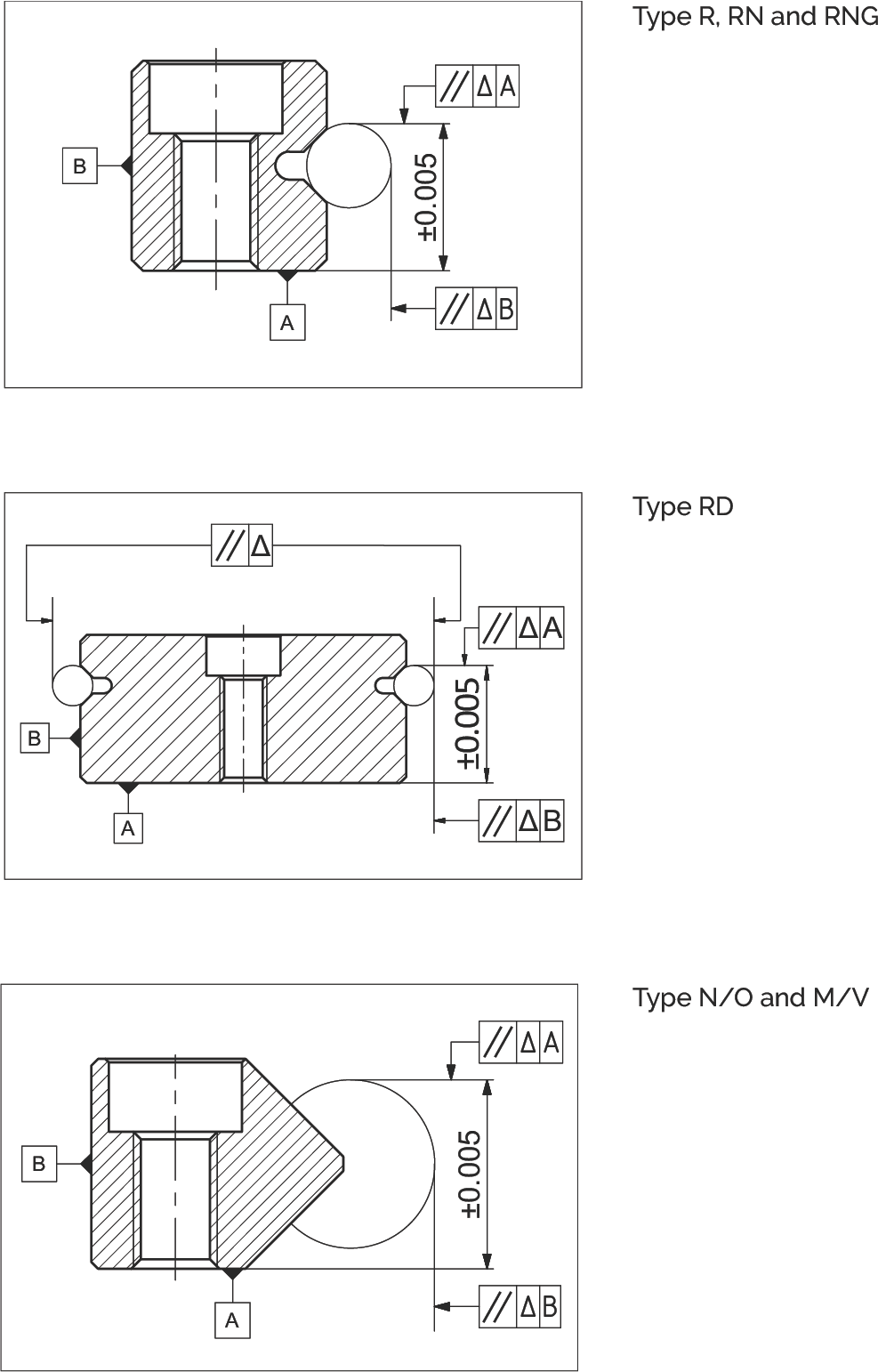

9.1 Tolerance of the Supporting Surface to the Track

In addition to the geometrical accuracy described in chapter 7.1, SCHNEEBERGER guideways are manufactured with very narrow tolerances (+/- 0.005mm) in relation to the dimensions of the supporting surface relative to the track.

Advantages:

- Interchangeability is always guaranteed

- In most cases, additional guideway matching is not required

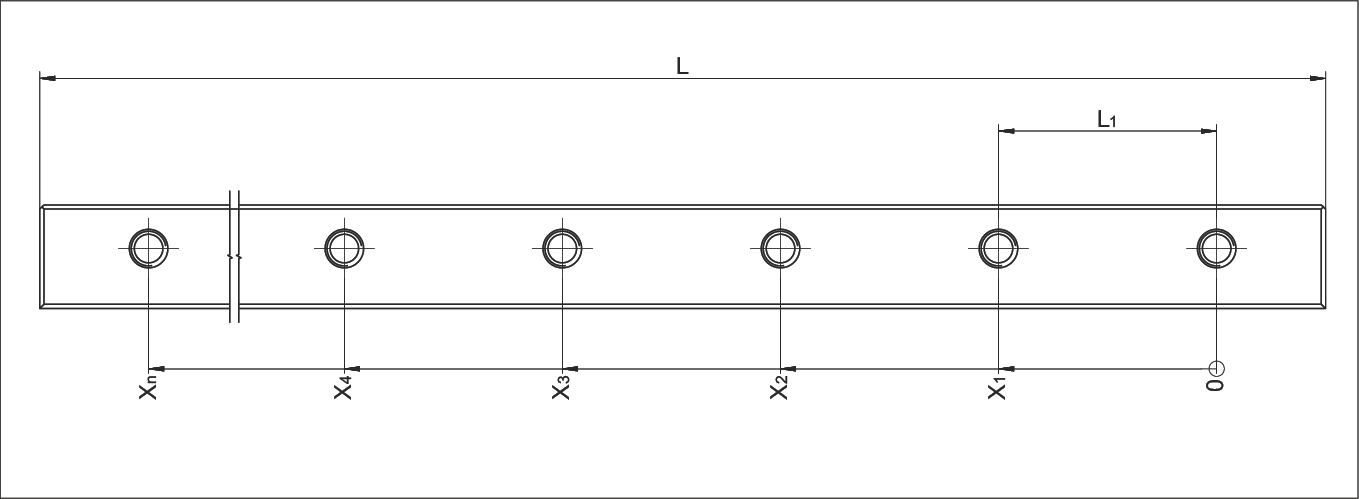

9.2 Length Tolerances and Distances Between Fixing Holes

| Length L ≤ 300 mm: | ±0.3 mm |

| Length L > 300 mm: | ±0.1% of L |

| Hole spacing L1: | ±0.3 mm |

| Dimension Xn ≤ 350 mm: | ±0.3 mm |

| Dimension Xn > 350 mm: | ±0.08% of xn |

The fixing holes are manufactured before the hardening process, which is why the length tolerances and spacings differ from the usual standards. The deviations can be compensated by using countersunk fastening screws of type GD or GDN (see chapter 5) and/or by selecting suitable holes (see chapter 7.10).

9.3 Operating Temperatures

SCHNEEBERGER linear guideways can be used at operating temperatures from –40°C to +80°C. Temperatures of up to +120°C can be achieved for short periods.

9.4 Speeds and Accelerations

The following limits apply for standard designs:

| Product | Max. Speed | Max. Acceleration |

|---|---|---|

| Linear guideways R, RD, RN, RNG, N/O and M/V | 1 m/s | 50 m/s² |

| Linear guideways RN and RNG with cage positioning FORMULA-S | 1 m/s | 300 m/s² |

| Linear guideways N/O and M/V with cage positioning | 1 m/s | 200 m/s² |

9.5 Friction, Running Accuracy and Smoothness

When manufacturing linear guideways, SCHNEEBERGER attaches great importance to a high degree of smoothness. The quality of transitions, run-ins and run-outs, or synthetic materials and synthetic composite cages, are all top priorities. This also applies to the rolling elements used, which must meet the strictest quality requirements.

For guideways with cages under normal operating conditions, a coefficient of friction of 0.0005 to 0.0030 can be assumed.