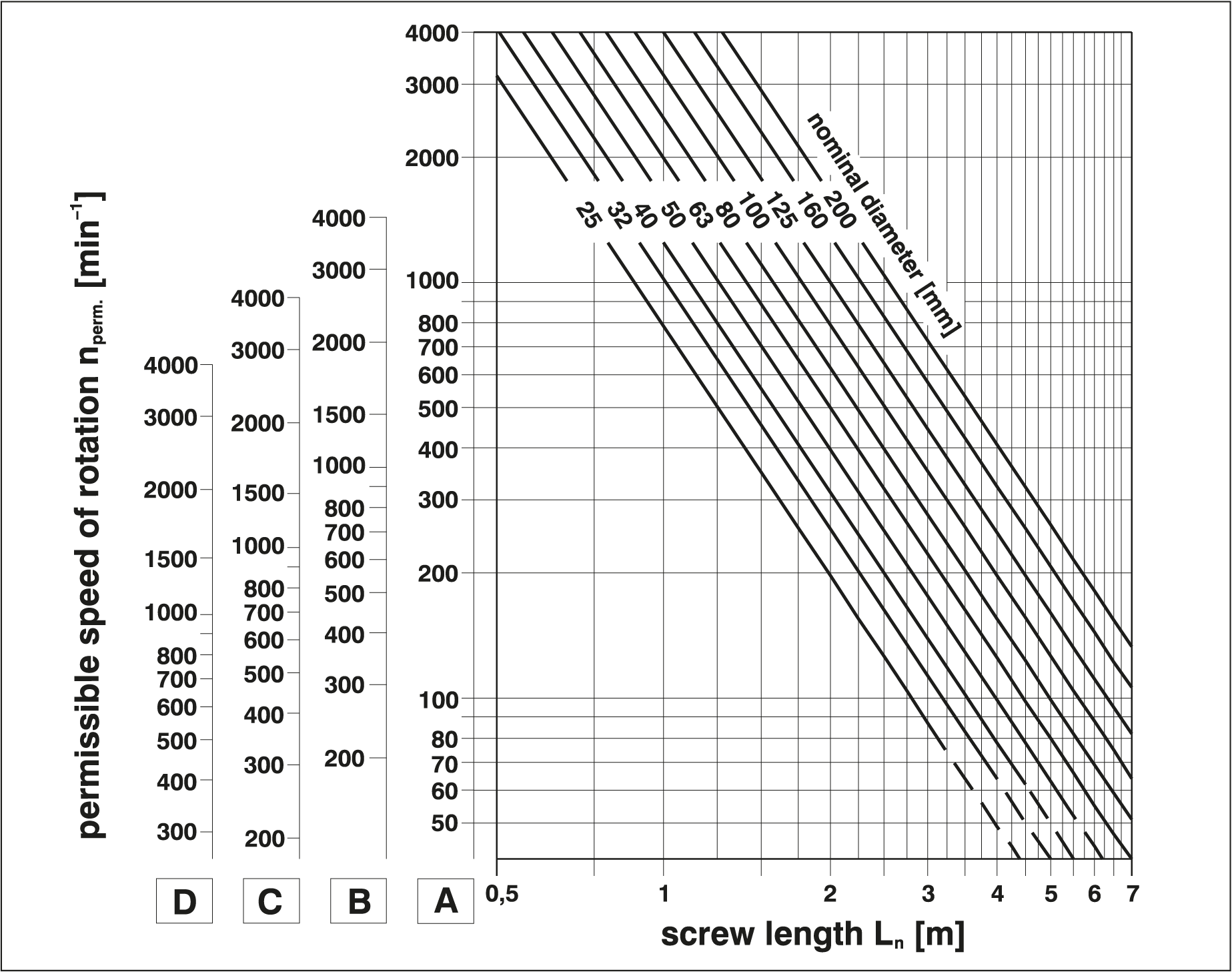

Permissible Speed Calculation

Permissible Speed Calculation

Calculated values should be regarded as approximations. For precise calculations, please contact us.

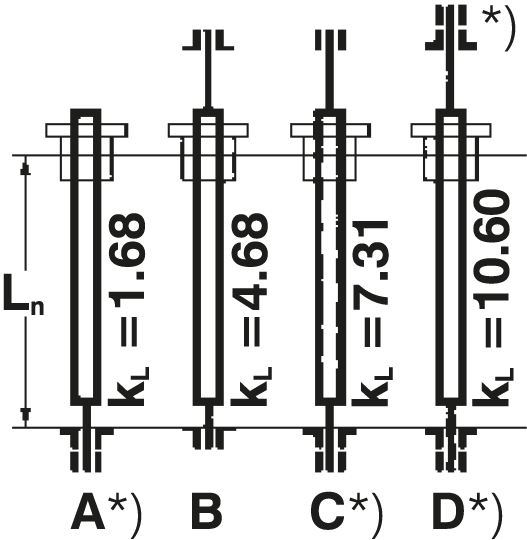

*) Directionally stable mounting

Transverse Resonant Vibration Transverse Resonant Vibration

Any shaft exceeding the permissible speed will excite transverse resonant vibration. On ball screws, this causes excessive radial loads on the nut system.

Safety Factor

The maximum permissible speed is 80% of the critical speed (20% below critical speed). This safety factor has been incorporated into the calculation chart above.

Importance of Bearing Arrangement Importance of Bearing Arrangement

The specific implementation of screw bearings has a significant impact on the permissible speed.

See data sheets for d0, dk

Screw Sagging Problem

Inadmissible Sagging of Screw

High Slenderness Ratio Screw Considerations

When the slenderness ratio Ln/d0 > 50, additional support must be provided in the free area of the thread length to prevent sagging. Otherwise, the ball screw will be operating under inadmissible conditions.

Note: This is equally important for driven nut systems!

Limit Application Consultation

When Ln/d0 > 40, please contact us for professional advice.

Slenderness Ratio Reference Table

Slenderness Ratio Reference

| Ln/d0 Range | Recommended Action |

|---|---|

| ≤ 40 | Standard design, no additional support required |

| 40 - 50 | Consultation recommended, special design may be required |

| > 50 | Additional support required to prevent sagging |

Symbol Reference

Symbol Reference

| Symbol | Description |

|---|---|

| Ln | Thread length |

| d0 | Nominal diameter |

| nperm | Permissible speed |

| ncrit | Critical speed |