SCHNEEBERGER MONORAIL offers a variety of special version options to meet the needs of specific application environments. This chapter introduces coating technology and stainless steel models, suitable for applications requiring higher corrosion resistance or special environmental conditions.

4.15.1 Coatings

Guide rails and carriages can be optionally equipped with special coatings to improve corrosion resistance and environmental adaptability.

Coating Types

Anti-Corrosion Coating

Suitable for humid or corrosive environments, providing additional surface protection.

Wear-Resistant Coating

Extends service life, suitable for high-load or high-frequency motion applications.

Low-Friction Coating

Reduces friction coefficient, improving motion smoothness and energy efficiency.

Application Recommendations

- Food processing equipment: Select coatings that meet hygiene standards

- Marine environment: Use highly corrosion-resistant coatings

- Cleanroom applications: Select low dust-generating coatings

- High-temperature environment: Use special high-temperature resistant coatings

Note

Coating selection should be based on comprehensive consideration of factors such as specific application environment, temperature range, and chemical substance exposure. Consultation with the SCHNEEBERGER technical team is recommended to select the most suitable coating solution.

4.15.2 Stainless Steel Models

The MONORAIL BM series offers stainless steel models (WR/SR), suitable for demanding environments requiring high corrosion resistance.

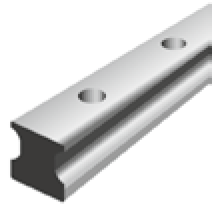

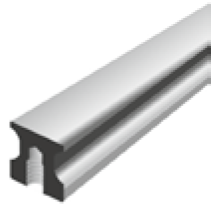

BM SR Stainless Steel Guide Rails

Stainless steel guide rails are manufactured from high-quality stainless steel materials with excellent anti-corrosion performance.

ND type guide rail (Standard) configuration

NUD type guide rail (Can be fastened from below) configuration

Product Models

| Size/Guide Rail Type | Model Variants | Characteristics | |

|---|---|---|---|

| ND Standard Fastening | NUD Can be Fastened from Below | ||

| Size 15 | BM SR 15-ND | BM SR 15-NUD | Light load applications |

| Size 20 | BM SR 20-ND | BM SR 20-NUD | Medium load applications |

| Size 25 | BM SR 25-ND | BM SR 25-NUD | Medium-high load applications |

| Size 35 | BM SR 35-ND | BM SR 35-NUD | Heavy-duty applications |

BM WR Stainless Steel Carriages

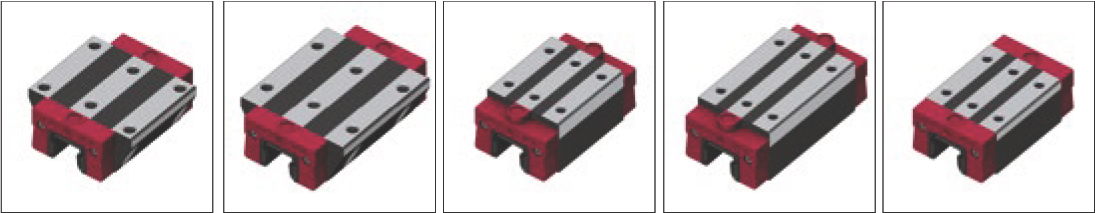

BM WR Carriage Configuration Types

Carriage Models

| Size/Guide Rail Type | Carriage Types | ||||

|---|---|---|---|---|---|

| A Standard | B Standard, Long | C Compact, High | D Compact, High, Long | F Compact, Flat | |

| Size 15 | BM WR 15-A | — | BM WR 15-C | — | BM WR 15-F |

| Size 20 | BM WR 20-A | BM WR 20-B | BM WR 20-C | BM WR 20-D | — |

| Size 25 | BM WR 25-A | BM WR 25-B | BM WR 25-C | BM WR 25-D | — |

| Size 35 | BM WR 35-A | BM WR 35-B | BM WR 35-C | BM WR 35-D | — |

Carriage Characteristics

| Characteristic | A | B | C | D | F |

|---|---|---|---|---|---|

| Mounting from above | ● | ● | ● | ● | ● |

| Mounting from below | ● | ● | — | — | — |

| Suitable for medium forces | ● | — | ● | — | ● |

| Suitable for high forces | — | ● | — | ● | — |

Note: ● = Applicable, — = Not applicable

Material Characteristics

- Material: High-quality stainless steel (compliant with relevant international standards)

- Corrosion resistance: Excellent anti-corrosion performance, suitable for humid or chemical environments

- Mechanical properties: Maintains load capacity and accuracy comparable to standard models

- Surface treatment: Guide rails are delivered without corrosion protection on the surface

- Lubrication: Carriages are supplied with lubricant to ensure reliable installation

Application Areas

- Food processing and packaging equipment

- Medical and pharmaceutical equipment

- Chemical and marine engineering

- Cleanroom applications

- Outdoor and harsh environment equipment

Important Notes

- The accessory product range for stainless steel models (additional wipers, metal wipers, lubrication plates) is only applicable to specified sizes and model variants

- When selecting, consider the differences in mechanical properties between stainless steel materials and standard steel

- Consultation with the SCHNEEBERGER technical team is recommended to ensure correct selection