AM Ball Screws - Manufacturing Drawing

Manufacturing Drawing - Economic Design Recommendations

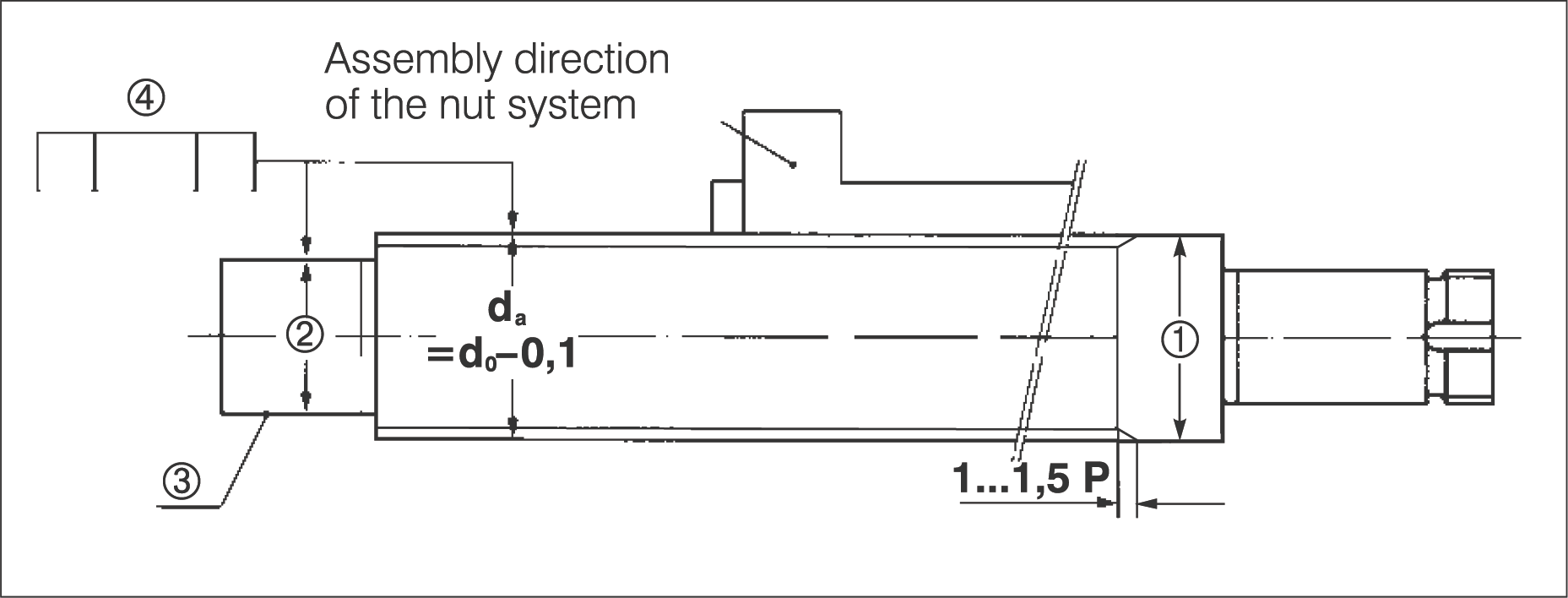

Economic Design Recommendations

Design Key Points

| Item | Recommendation |

|---|---|

| 1. Flange Diameter | Flange diameter ≦ screw outer diameter da. Avoid flange diameter larger than da if possible. |

| 2. Shaft Diameter | Shaft diameter on at least one side of the thread for nut assembly, d = dk = d0 - ball diameter - 0.5 (also applies to undercut grooves). |

| 3. Deep Nitriding | AM ball screws have deep nitrided bearing seats. Please identify all surfaces that must remain unhardened. Fine pitch threads always remain unhardened. |

| 4. Geometric Tolerances | Geometric tolerances according to DIN 69051. |

| 5. Series Design | Provide screws of different lengths - with the same nominal diameter and lead - with identical screw ends and nuts ("part families"). |

| 6. Standard Nuts | Consider nuts conforming to German standard DIN, preferably AM standard 2.51 or 2.52. |

Drawing Specification Requirements

Please include the following performance characteristics in your drawings:

| Characteristics | Symbol | Value / Option | Unit |

|---|---|---|---|

| Nominal diameter | d0 | mm | |

| Nominal lead | P | mm | |

| Direction of lead | L.H. (Left-hand) R.H. (Right-hand) | ||

| ISO precision class | IT type | ||

| Tolerance of specified lead | ±ep | µm/lu | |

| Variation | V300p | µm | |

| Type of nut system (abbr.) | type No. | ||

| Nut rigidity | Rnu | kN/µm | |

| - No-load torque without wipers | Tpr0 | Nm | |

| - Preload | Fpr | kN | |

| Mean load | Fm | kN | |

| Mean speed of rotation | nm | min-1 | |

| Max. speed of rotation | nmax | min-1 | |

| Acceleration | a | m/sec² | |

| Moved mass | m | kg | |

| Lubrication | |||

| Mounting position | Horizontal Vertical | ||

| Driven element | Nut Screw |

Design Checklist

Drawing Review Points

- Confirm flange dimensions do not exceed screw outer diameter

- Check shaft diameter meets nut assembly requirements

- Mark areas that need to remain unhardened

- Confirm geometric tolerances conform to DIN 69051

- Consider using standard nuts to reduce costs

- For series products, unify screw end design