16.2 Installation Methods

Different criteria must be considered when selecting the appropriate installation method and defining the number and configuration of lateral reference surfaces. These include:

16.2.1 Load

Forces in the tension/compression direction have no effect on the lateral reference surface. If lateral loads exceeding the permissible lateral force occur, reference surfaces and lateral clamping must be specified. The number and direction depend on the forces occurring.

Reference surfaces should be configured according to the force direction of the main load. Lateral references should also be provided when vibration and shock occur. They also increase system rigidity.

16.2.2 Accuracy

If a high level of guideway accuracy is required, lateral reference surfaces are recommended. Reference surfaces make installation easier and reduce the complexity involved in ensuring accuracy. Guideway accuracy is determined by the straightness of the reference surface and the precision of the guide rail pressing process and/or lateral clamping.

16.2.3 Installation Time and Engineering Costs

Reference surfaces make installation easier and reduce the complexity involved in aligning the guide rails.

The need for lateral reference surfaces can be eliminated through careful manual alignment of the guide rail. When deciding on a method, the complexity of installation should be carefully weighed against the design and technical manufacturing complexity.

16.2.4 Installation Position and Characteristics

Reference surfaces and lateral clamping require additional installation space and access to the installation area. Therefore, it is important to check whether the provided reference and adjustment are compatible with the installation area in the machine.

Some typical installation methods are shown below, which differ in the number and direction of reference surfaces, transferable lateral forces, and installation complexity, and are intended as design aids.

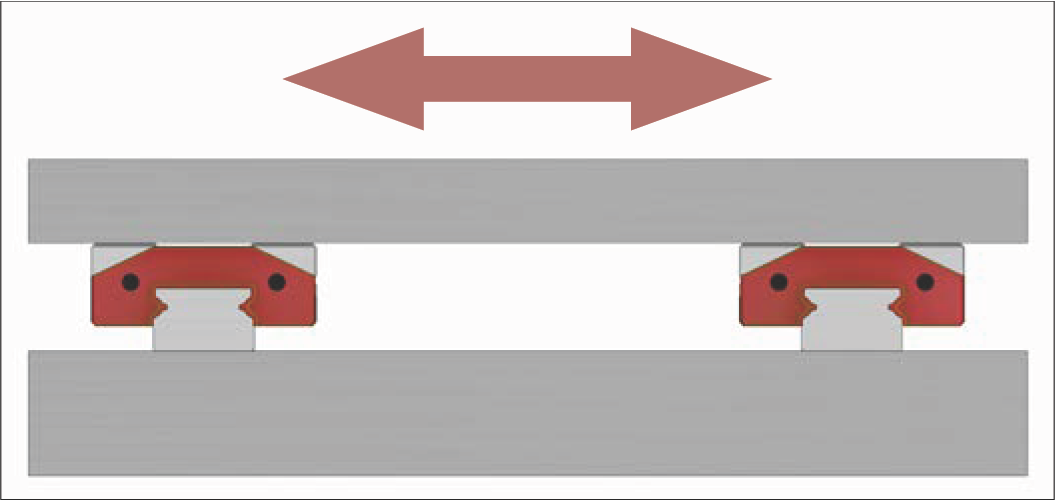

Installation Option 1

- No reference surface

- Force transmitted through friction lock

- Long installation time and high engineering costs

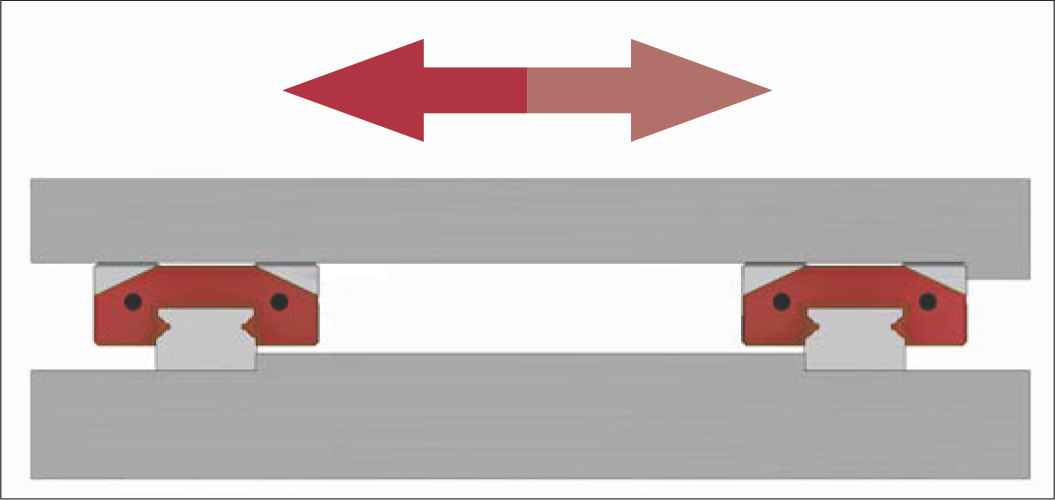

Installation Option 2

- One reference on each of the two guide rails with opposite references on carriage side

- Simple installation

- High lateral force absorption from one direction, e.g. for suspended installation

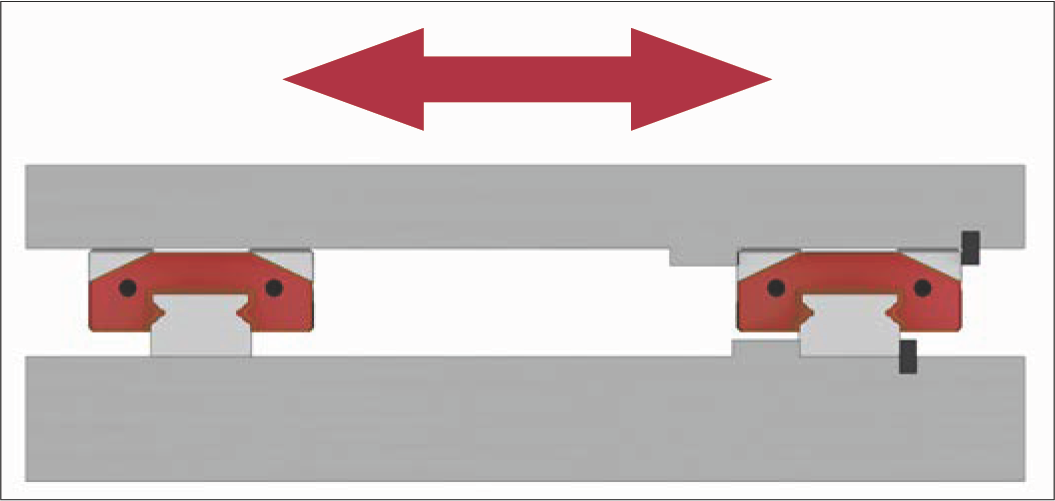

Installation Option 3

- One guide rail and carriage with reference and lateral clamping

- For high lateral forces from both directions (guide rail with carriage will bear most of the lateral force)

- Relatively simple installation