SCHNEEBERGER linear guideway systems are widely used in various precision machinery and equipment. The following showcases real-world applications across different fields, demonstrating how to select the appropriate linear guideway products for specific requirements.

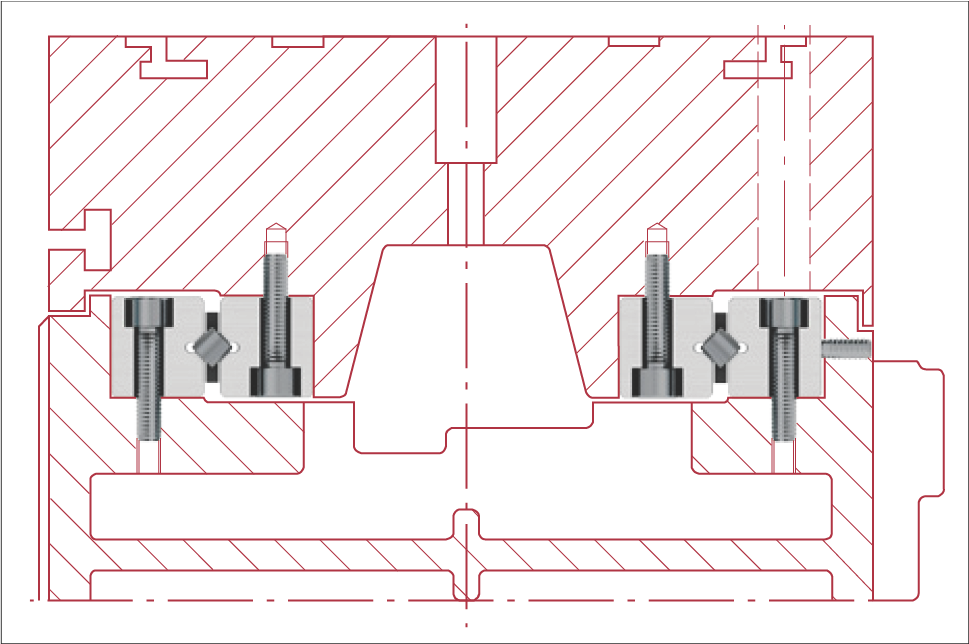

Linear guideways for tool grinding machine table

Precision grinding on tool grinding machines requires stick-slip and friction-free guideways for the longitudinal movement of the worktable.

SCHNEEBERGER products available:

- 4 linear guideways type R 9-800

- 2 roller cages AC 9 x 33 rollers

- 8 closures GA 9, GB 9

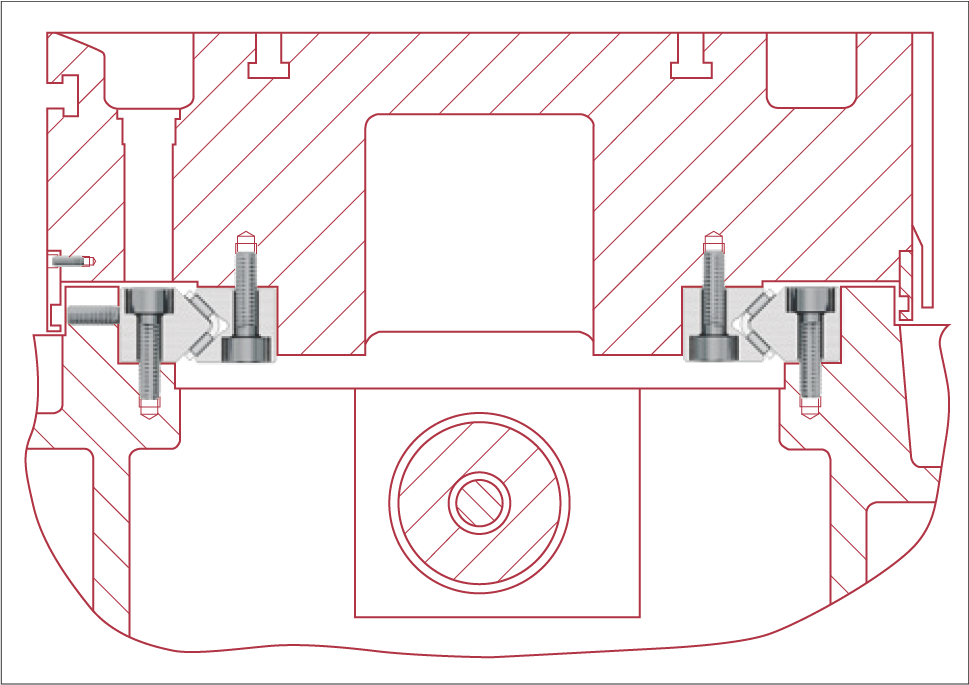

Table bearing for internal cylindrical grinding machine

An internal cylindrical grinding robot requires absolutely backlash-free table guidance to meet the stringent requirements of today's grinding technology.

The grinding table shown uses type N/O linear guideways with V-shaped needle roller cages connected to an oil pulse lubrication system. This creates the conditions required for high table speeds with minimal application of force.

SCHNEEBERGER products available:

- 2 linear guideways type O 2535-1'000

- 2 linear guideways type N 2535-1'000

- 2 needle roller cages HW 20 x 725

- 4 closures GH 2535 (without wiper)

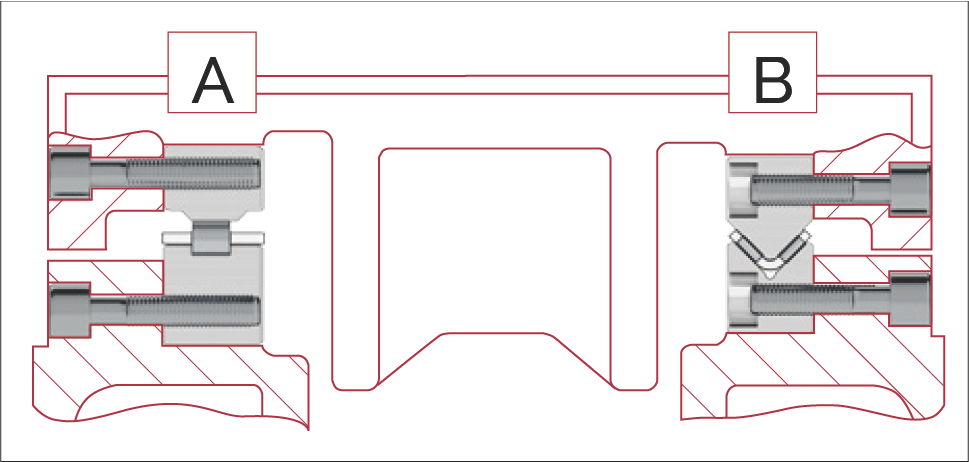

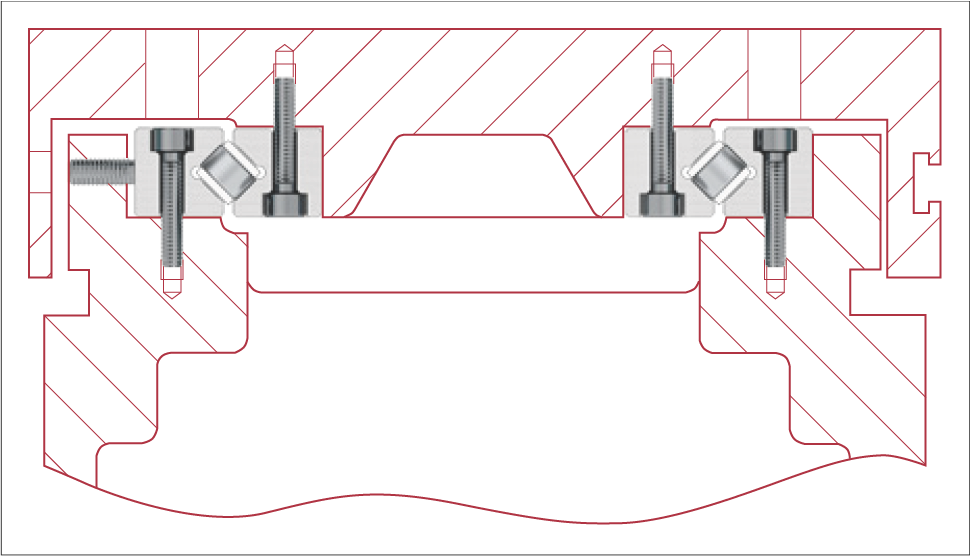

Open configuration (floating bearing) for heavy surface grinding machines

When machining large and heavy workpieces, surface-mounted roller guideways are particularly suitable. The weight of the table and workpiece as well as grinding pressure act vertically on the roller guideways.

Cost effectiveness, simple assembly and high running accuracy characterize this configuration. The characteristic of the expansion option also prevents unrestricted expansion of the worktable due to thermal effects.

Its construction is simple and economical. The N/O linear guideways take on the task of lateral linear guidance of the table. Since the surface guideways are aligned flush with the N/O, the linear guideway system is interchangeable - depending on whether the grinding spindle is mounted on the right or left side.

SCHNEEBERGER products available:

Configuration A:

- 1 linear guideway spec. 45 x 35 x 600-EG

- 1 linear guideway spec. 45 x 42.5 x 1'000

- 1 roller cage H 25 x 810 mm

- 2 special closures

Configuration B:

- 1 linear guideway type N 3555-600-EG

- 1 linear guideway type O 3555-1'000

- 1 needle roller cage SHW 30 x 810 mm

- 2 closures GW 3555

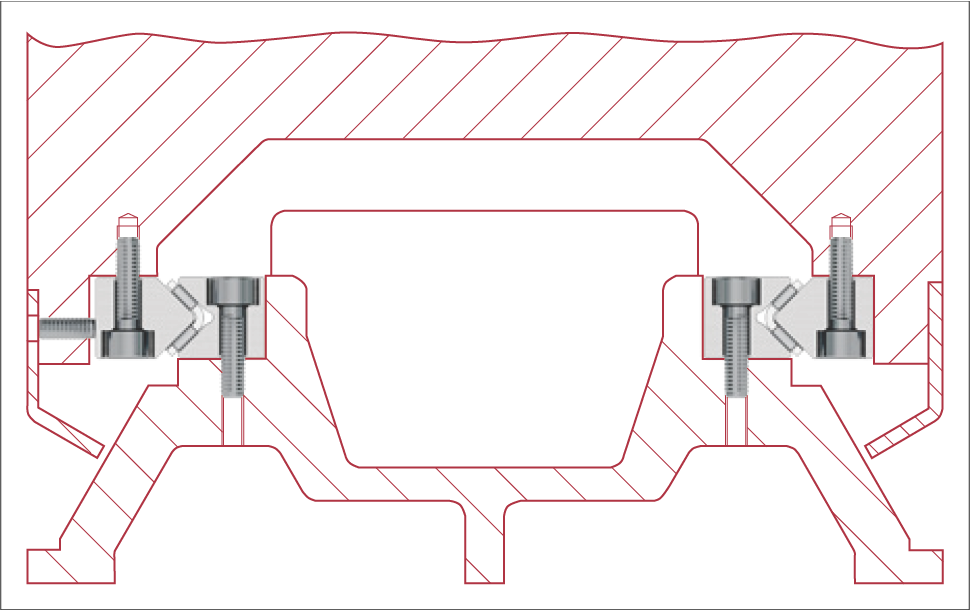

Closed V guideway for surface grinding machines

Economic aspects also determine the structural design of the worktable guideways on surface grinding machines. The V-shaped configuration of the roller guideways creates a closed linear guideway that can absorb forces and moments from all directions.

The low number of components ensures fast and simple assembly. The stroke to table length ratio is optimal for the use of roller guideways. The base surfaces for the roof-shaped linear guideways can be machined with extremely high efficiency and accuracy because they lie in the same plane. These surfaces also form the basis for achieving high running accuracy.

SCHNEEBERGER products available:

- 2 linear guideways N 3045-900

- 2 linear guideways O 3045-900

- 2 needle roller cages SHW 25 x 730 mm

- 8 closures GF 3045

V guideways for heavy tool grinding machines

Tool grinding machines place very high demands on the roller guideway system of the machine table. High level of running accuracy, minimal friction, stick-slip effect and protected arrangement of the roller guideways are the most important requirements.

The RNG roller guideways used here are ideally suited to this task with their high load capacity. The table structure allows accommodation of the drive mechanism; the upper part of the table can also be mounted very easily. The preload of the linear guideway system can also be easily set afterwards.

SCHNEEBERGER products available:

- 2 linear guideways RNG 9-700

- 2 linear guideways RNG 9-450-EG

- 2 roller cages KBN 9 x 43 rollers

- 4 closures GCN 9

Infeed device

An infeed device operating in a vacuum places high demands on the linear guideway system. The U-shaped support forms the supporting element and also serves as the mounting seat for the linear guideways. The entire system is made of non-corrosive materials, operates vertically with a stroke of 2,700 mm.

The linear guideways assembled in the U-shaped basic component and the 4 type SK rolling elements constitute the actual guidance system. Two of the four rolling elements can be adjusted from the outside, thus supporting optimal preload settings. All individual components of the rolling elements are made of stainless steel or aluminum.

SCHNEEBERGER products available:

- 4 linear guideways R 9-1400-RF-ZG

- 4 recirculating units SK 9-150-RF

Patient tables

Highly developed automatic patient tables are used in areas such as computed tomography (CT), magnetic resonance tomography (MRT), or radiation therapy.

All motion processes place the highest demands on the linear guideway system in terms of running accuracy, smoothness, maintenance-free operation, rigidity, ease of installation and radiation resistance.

SCHNEEBERGER products available:

- R 9 linear guideways

Microtome

Microtomes are cutting devices used to create wafer-thin sections. They are used for microscopic preparations (for example, biological tissue) or analysis of plastics.

Biological material is usually hardened by fixation before cutting and then made cuttable by "embedding" (i.e., surrounding with fluid substances such as paraffin or synthetic resin). The section thickness is significantly less than the diameter of a human hair, typically between 1 and 100 µm.

Due to these special requirements, the strictest demands are placed on the smoothness and accuracy of the linear guideway system.

SCHNEEBERGER products available:

- RNG 4 linear guideways

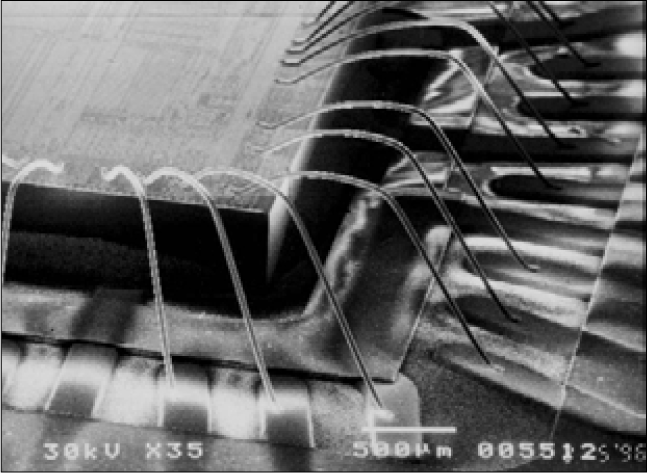

Wire bonder

Wire bonding is the preferred method for making connections between integrated circuits (ICs) and printed circuit boards. Wire bonding generally represents the most cost-effective and flexible bonding technology, in which the finest wires are used for bonding electrical connections.

This technology typically uses aluminum, copper or gold wire with diameters starting from 15 µm. The demands on the linear guideway system for wire bonding machines are correspondingly stringent:

- Highest precision and rigidity

- Highest speed

- Highest smoothness

- Highest reliability

SCHNEEBERGER products available:

SCHNEEBERGER supplies customized linear guideway systems for well-known wire bonding machine manufacturers.

Aluminum wire with a diameter of 25 µm connects the electrodes of the microchip with the conductive traces of the carrier substrate

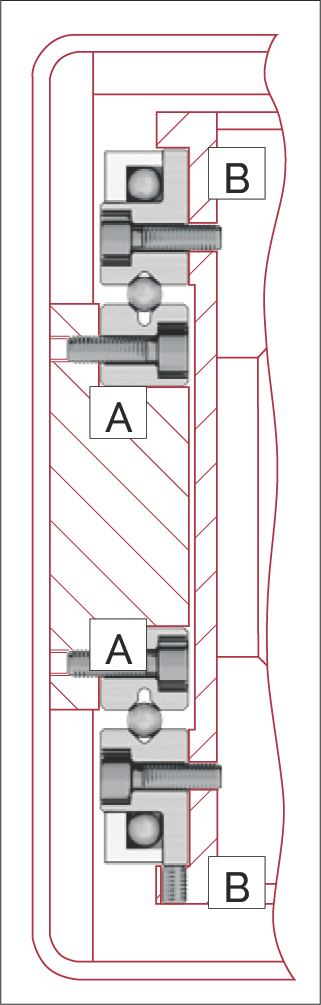

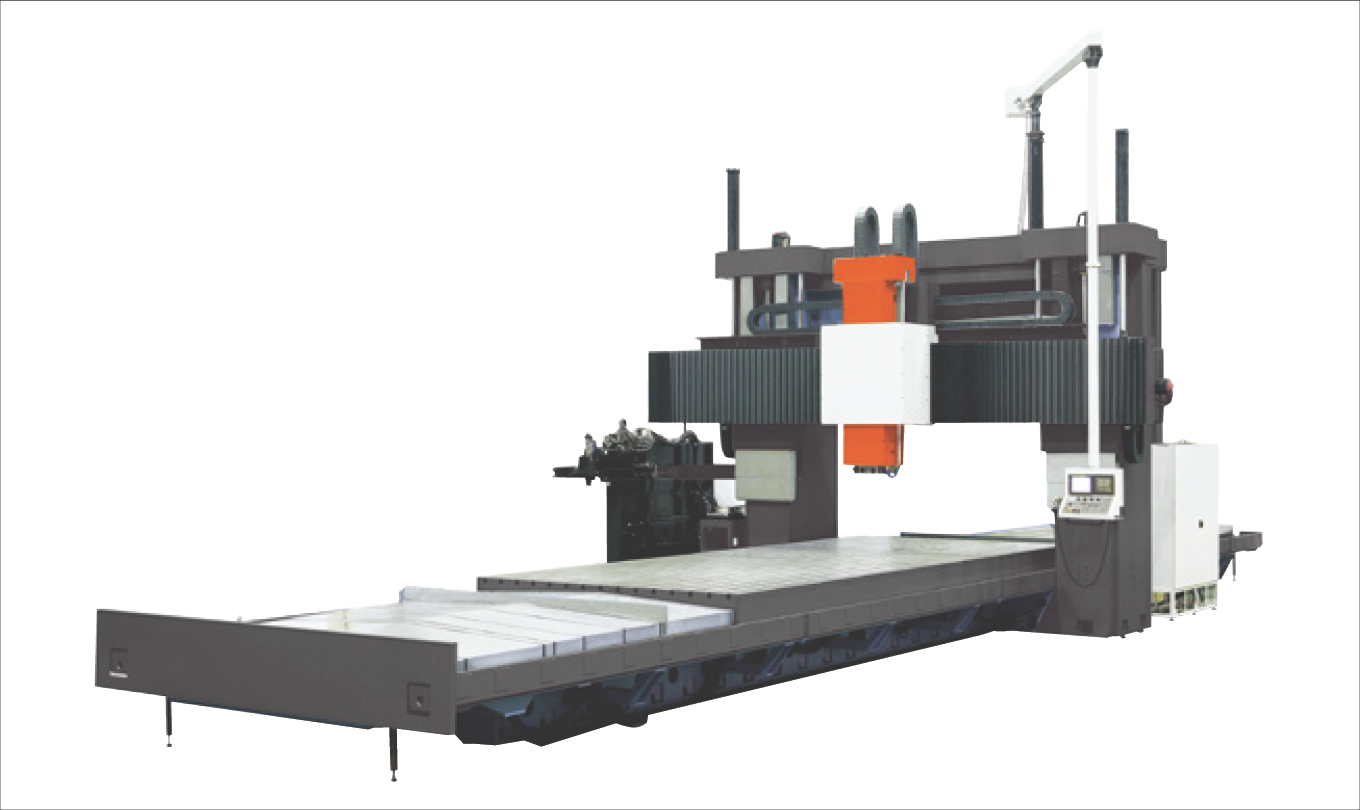

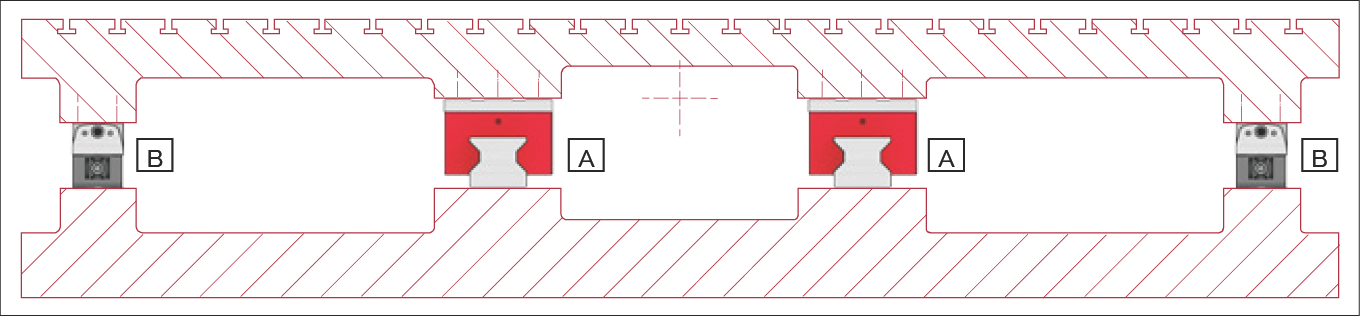

Large-scale machining center

To ensure high-precision manufacturing under the most stringent loads, rigid and precision linear guideway systems are essential.

SCHNEEBERGER products available:

A MONORAIL MR 65

B Recirculating unit NRT

with preload wedge NRV

Application Guide

The above application examples demonstrate the versatility of SCHNEEBERGER linear guideway systems across different industries and applications. Whatever your application requirements, SCHNEEBERGER can provide the appropriate solution.

For more technical information or customized solutions, please contact the SCHNEEBERGER technical support team.