MR Size 25 Technical Specifications

Medium-load applications in compact spaces

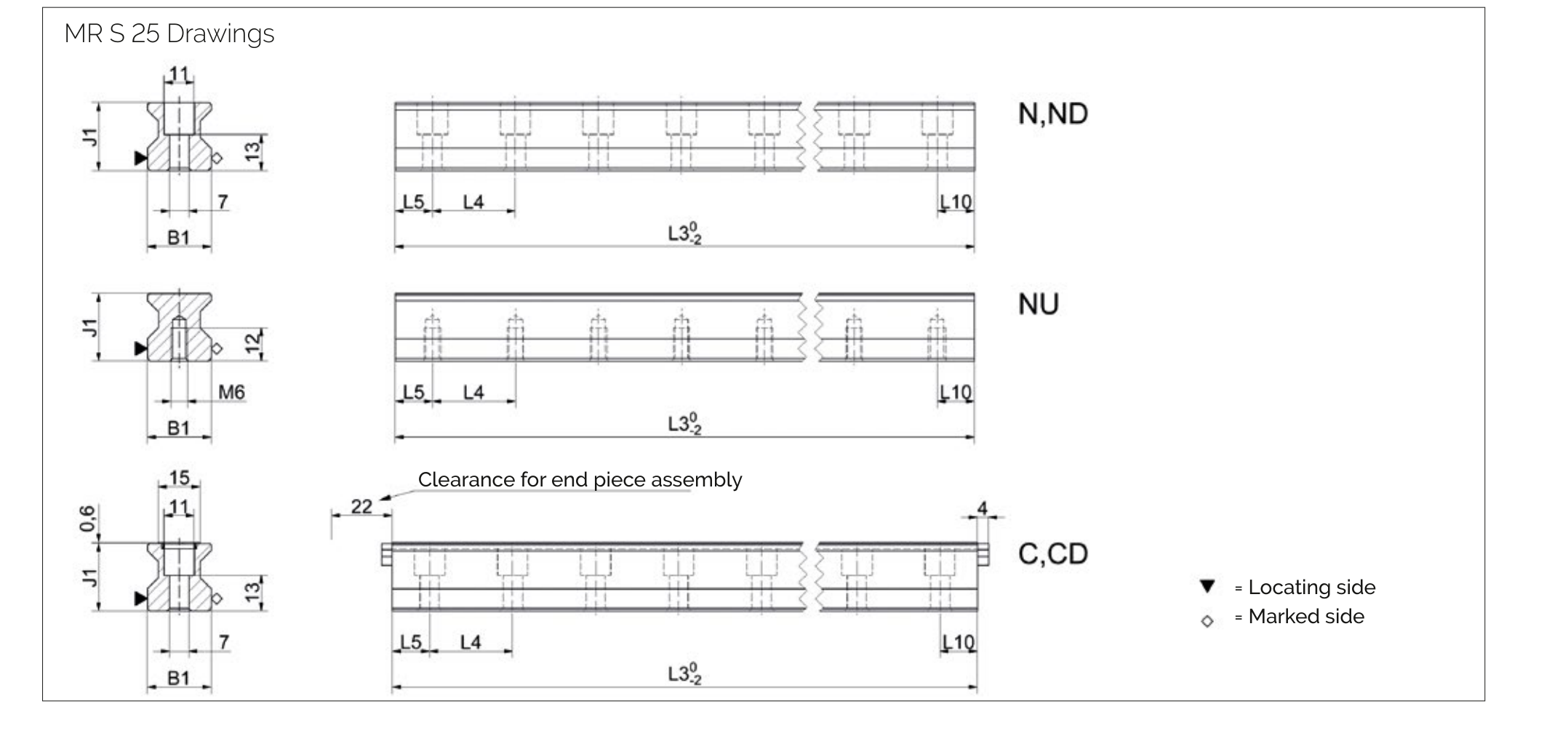

Rail Types MR S 25

| MR S 25-N | MR S 25-ND | MR S 25-NU | MR S 25-C | MR S 25-CD |

|---|---|---|---|---|

|  |  |  |  |

| Standard Top mounting | Standard, through-hardened Through-hardened | Bottom threaded hole Bottom mounting | Cover strip type For cover strip | Through-hardened cover strip Through-hardened |

Rail Dimensional Drawing MR S 25

Rail Specifications MR S 25

| Parameter | MR S 25-N | MR S 25-ND | MR S 25-NU | MR S 25-C | MR S 25-CD |

|---|---|---|---|---|---|

| Rail Width B1 (mm) | 23 | 23 | 23 | 23 | 23 |

| Rail Height J1 (mm) | 24.5 | 24.5 | 24.5 | 24.5 | 24.5 |

| Max. Single Length L3 (mm) | 6000 | 1500 | 6000 | 3000 | 1500 |

| Hole Pitch L4 (mm) | 30 | 30 | 30 | 30 | 30 |

| First/Last Hole Position L5/L10 (mm) | 13.5 | 13.5 | 13.5 | 13.5 | 13.5 |

| Weight per Unit (kg/m) | 3.4 | 3.4 | 3.8 | 3.3 | 3.3 |

Model Designations

- N = Standard (top mounting)

- ND = Standard, through-hardened

- NU = Bottom threaded hole (bottom mounting)

- C = Cover strip type

- CD = Through-hardened cover strip type

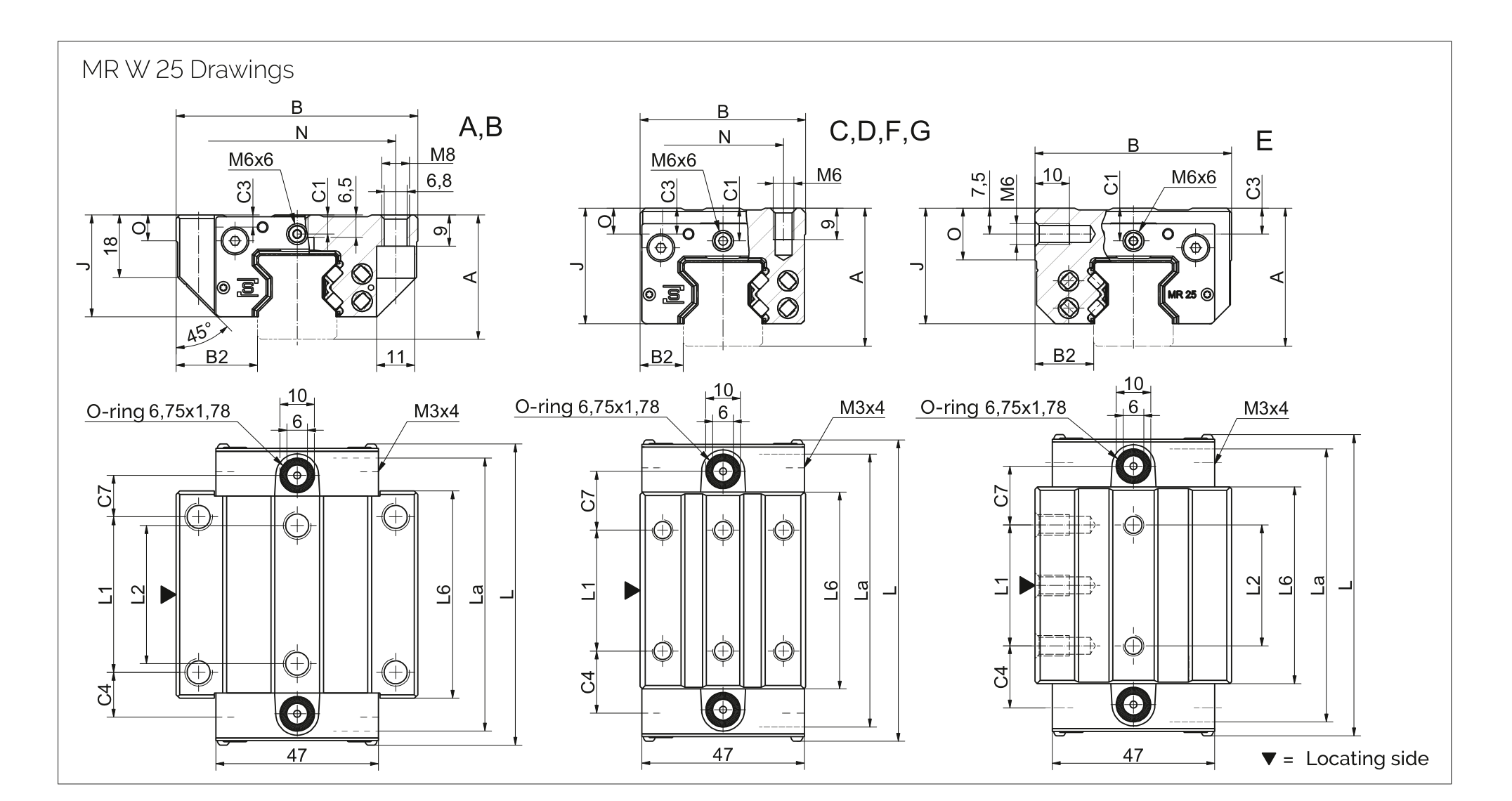

Carriage Types MR W 25

| MR W 25-A | MR W 25-B | MR W 25-C | MR W 25-D | MR W 25-E | MR W 25-F | MR W 25-G |

|---|---|---|---|---|---|---|

|  |  |  |  |  |  |

| Standard Standard | Standard long Standard long | High/flat High/flat | High/flat long High/flat long | Side fixing Side fixing | Flat Flat | Flat long Flat long |

Carriage Dimensional Drawing MR W 25

Carriage Specifications MR W 25

| Parameter | MR W 25-A | MR W 25-B | MR W 25-C | MR W 25-D | MR W 25-E | MR W 25-F | MR W 25-G |

|---|---|---|---|---|---|---|---|

| System Height A (mm) | 36 | 36 | 40 | 40 | 40 | 36 | 36 |

| Carriage Width B (mm) | 70 | 70 | 48 | 48 | 57 | 48 | 48 |

| Reference Distance B2 (mm) | 23.5 | 23.5 | 12.5 | 12.5 | 17 | 12.5 | 12.5 |

| Carriage Height J (mm) | 29.5 | 29.5 | 33.5 | 33.5 | 33.5 | 29.5 | 29.5 |

| Carriage Length L (mm) | 88 | 110 | 88 | 110 | 88 | 88 | 110 |

| Transverse Wiper Distance La (mm) | 83 | 106 | 83 | 106 | 83 | 83 | 106 |

| Outer Hole Pitch L1 (mm) | 45 | 45 | 35 | 50 | 35 | 35 | 50 |

| Inner Hole Pitch L2 (mm) | 40 | 40 | — | — | 35 | — | — |

| Steel Body Length L6 (mm) | 60 | 79.4 | 57 | 79.4 | 57 | 57 | 79.4 |

| Side Hole Pitch N (mm) | 57 | 57 | 35 | 35 | — | 35 | 35 |

| Reference Height O (mm) | 7.5 | 7.5 | 7.5 | 7.5 | 15 | 7.5 | 7.5 |

| Carriage Weight (kg) | 0.7 | 0.9 | 0.6 | 0.7 | 0.7 | 0.5 | 0.6 |

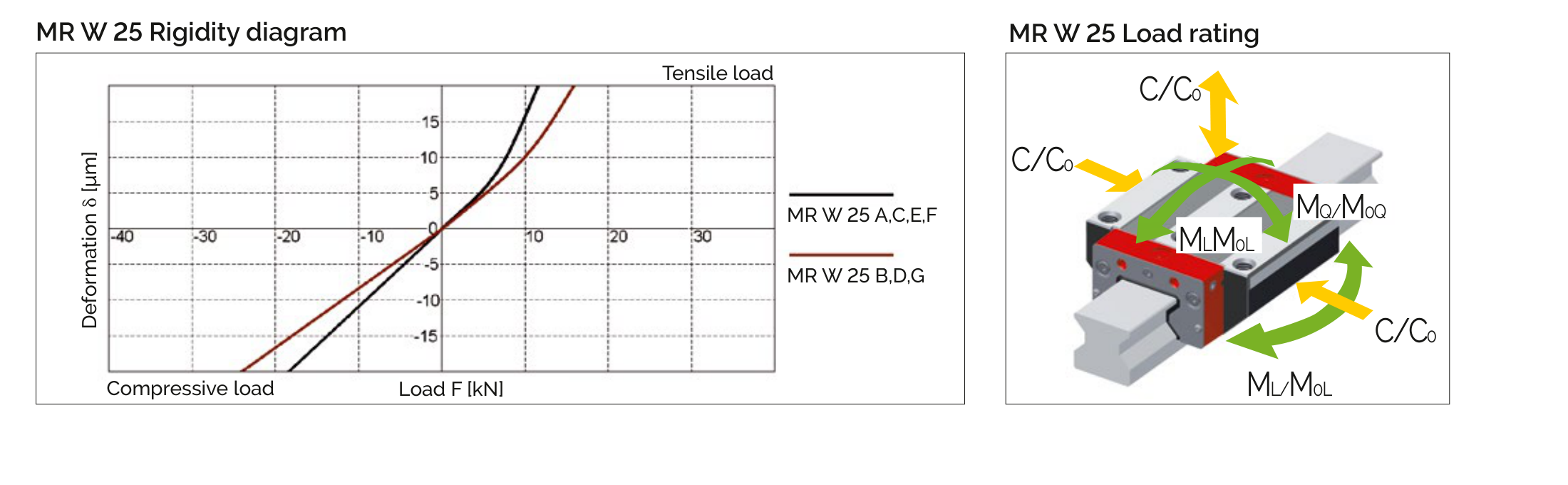

Rigidity Curves and Load Rating Diagrams

Load Ratings

| Carriage Type | C₀ Static Load (N) | C₁₀₀ Dynamic Load (N) | M₀Q Static Cross Moment (Nm) | M₀L Static Long. Moment (Nm) | MQ Dynamic Cross Moment (Nm) | ML Dynamic Long. Moment (Nm) |

|---|---|---|---|---|---|---|

| A / C / E / F | 49,800 | 27,700 | 733 | 476 | 408 | 264 |

| B / D / G | 70,300 | 39,100 | 1,035 | 936 | 575 | 520 |

Load Rating Definitions

- C₀ = Static load capacity - Maximum allowable load causing permanent deformation

- C₁₀₀ = Dynamic load capacity - Load for 100km travel life

- M₀Q / MQ = Cross moment - Rotation around travel axis

- M₀L / ML = Longitudinal moment - Rotation around vertical axis

Available Options

Accuracy Classes

| Accuracy Class | Carriage & Rail Tolerance A/B2 | Max. Deviation Paired Carriages ΔA/ΔB2 | Max. Deviation Standard Carriages |

|---|---|---|---|

| G0 Highly accurate | ± 5 µm | 3 µm | 10 µm |

| G1 Very accurate | ± 10 µm | 5 µm | 20 µm |

| G2 Accurate | ± 20 µm | 7 µm | 40 µm |

| G3 Standard | ± 30 µm | 25 µm | 60 µm |

Preload Classes

| Preload Class | Preload Force (% of C₀) | Applications |

|---|---|---|

| V0 Very light preload | 0-2% | Very low friction, uniform load, minimum vibration |

| V1 Light preload | 3% | Low friction, uniform load, slight vibration |

| V2 Medium preload | 8% | High rigidity, moderate varying loads and vibration |

| V3 High preload | 13% | Maximum rigidity, impact loads, severe varying loads |

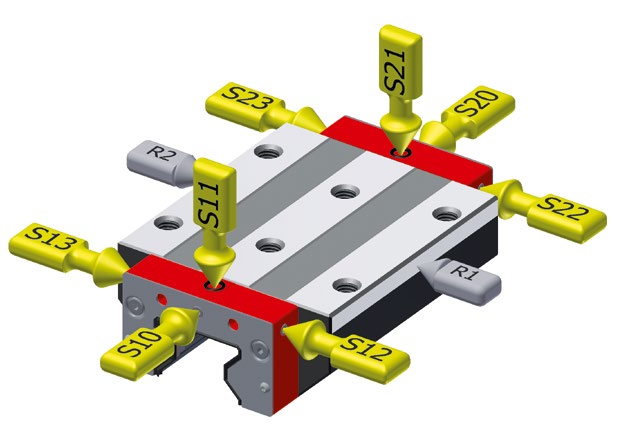

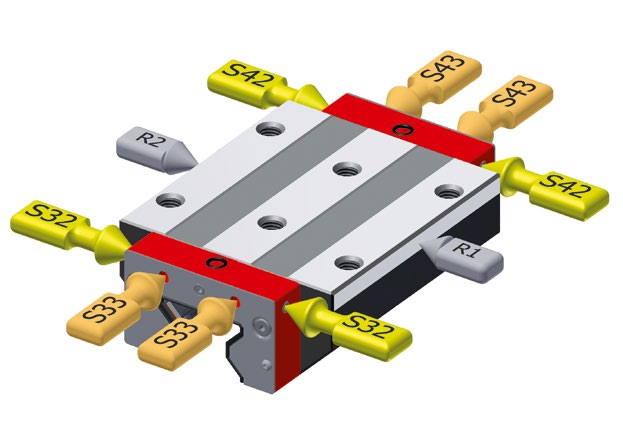

Lubrication Port Positions

| Code | Position | Description |

|---|---|---|

| S10 | Left center | Left center of front plate |

| S11 | Top center | Top center of carriage |

| S12 | Top left | Top left of carriage |

| S13 | Lower left side | Lower left side of carriage |

| S20 | Right center | Right center of front plate |

| S21 | Rear center | Center of rear plate |

| S22 | Top right | Top right of carriage |

| S23 | Lower right side | Lower right side of carriage |

| S32 | Upper left side | Upper left side of carriage |

| S42 | Upper right side | Upper right side of carriage |

| S98 | Special position | As per customer specification |

| S99 | Special position | As per customer specification |

Lubrication as Delivered

| Code | Type | Description | Applications |

|---|---|---|---|

| LN | Oil protection | Light oiling | Applications with continuous oil supply after installation |

| LG | Grease protection | Thin grease layer | Applications with continuous grease supply after installation |

| LV | Full greasing | Complete grease filling | Applications with manual lubrication |

Surface Treatment (Coating)

| Code | Type | Features |

|---|---|---|

| — | Standard (uncoated) | Standard steel surface |

| CN | Hard chromium | Excellent corrosion protection, high wear resistance, good emergency running properties |

Reference Side Position

R1 - Reference at bottom R2 - Reference on top

Order Code Examples

Rail Order Code

MR S 25-N-G1-KC-R1-600-13.5-13.5-CN

- MR S 25 = MONORAIL Rail Size 25

- N = Standard type

- G1 = High precision

- KC = Countersunk holes

- R1 = Reference at bottom

- 600 = Rail length 600mm

- 13.5-13.5 = First/last hole positions

- CN = Hard chrome plating

Carriage Order Code

MR W 25-A-G1-V2-R1-CN-S11-LV

- MR W 25 = MONORAIL Carriage Size 25

- A = Standard type

- G1 = High precision

- V2 = Standard preload (4% C₀)

- R1 = Reference at bottom

- CN = Hard chrome plating

- S11 = Lubrication port at top center

- LV = Full grease fill as delivered