4.13.1 Delivered Condition

Carriages in SCHNEEBERGER MONORAIL guideways are supplied as standard with protective-grade oil or grease on the guide rails. This is sufficient for protection during guideway assembly. Depending on application requirements, required storage period, and type of lubrication during operation, different options can be selected. For ordering details, please refer to the SCHNEEBERGER MONORAIL and AMS product catalog:

Oil Protection

Order code: LN

Grease Protection

Order code: LG

Full Grease Filling

Order code: LV

Lubricants Used

Lubricating Oil for Oil Protection

Mineral-based lubricating oil with anti-corrosion and anti-foam additives, excellent VI and demulsification properties, good seal compatibility, high oxidation stability, viscosity grade ISO VG 32. See Section 1.12 - Lubrication.

Lubricating Grease for Grease Protection

Mineral oil-based lithium complex soap grease with anti-wear and anti-corrosion additives, suitable for high loads, soft consistency, NLGI grade 2.

The lubricants used by SCHNEEBERGER are mineral oil-based greases or oils. They are compatible with other mineral oil-based lubricants. However, compatibility with the lubricant being used must be checked. Please contact your SCHNEEBERGER representative for this.

Protection Methods

Oil protection is suitable for applications where continuous lubrication is guaranteed during installation and operation phases (order code: LN) or grease protection (order code: LG).

Caution

Component damage due to lack of lubricant

- Before commissioning, the customer must perform initial lubrication with the lubricant quantity required for operation, applicable for oil or grease protection. For lubricant quantities, see "Grease Lubrication" and "Oil Lubrication" sections.

Note

- For applications with manual re-lubrication, full grease filling (order code: LV) is recommended. This means the carriage is completely filled with grease around the rolling element circulation unit. In this case, the customer does not need to perform initial lubrication before commissioning.

4.13.2 Initial and Subsequent Lubrication

Carriages should never be commissioned without initial lubrication. The compatibility of the lubricant used with the factory rust preventive should be checked. Greases containing solid lubricant components (such as graphite or MoS₂) should not be used. The required lubricant quantity can be found in Section 4.15.6 "Grease Lubrication" or Section 4.15.7 "Oil Lubrication". If the carriage is pre-lubricated at the factory, initial lubrication can be omitted.

To maintain the operation of SCHNEEBERGER MONORAIL guideways, in addition to initial lubrication, regular subsequent lubrication is usually required. See Section 4.15.3 - Lifetime Lubrication.

For subsequent lubrication, use the same lubricant as for initial lubrication and check compatibility.

The required lubricant quantity and subsequent lubrication intervals can be found in Section 4.15.6 "Grease Lubrication" or Section 4.15.7 "Oil Lubrication".

These specifications apply to normal operating conditions and clean working environments. However, in practice, lubricant consumption depends on many factors and can vary greatly depending on individual usage. More frequent subsequent lubrication may be required to counteract adverse effects such as coolant deposits, high speeds, very short or long strokes, elevated temperatures, high forces, and vibration.

4.13.3 Lifetime Lubrication

Grease lubrication, even when combined with additional lubricant distributors (such as lubrication plate SPL), is an effective minimal volume form often referred to as lifetime lubrication. When operating SCHNEEBERGER MONORAIL guideways, as a principle, lubricant escapes from the carriage due to linear motion and is distributed on the guide rail. Under the influence of dirt or coolant, this lubricant may combine or be washed away and must therefore be replaced. Otherwise, the grease changes its consistency due to oil diffusion from the carrier substance.

These situations require subsequent lubrication. This also applies when using lubrication plate SPL, which significantly extends subsequent lubrication intervals due to the increased amount of lubricant available from the additional oil reservoir.

Subsequent lubrication quantities and intervals must be determined under actual operating conditions. Depending on the individual application, i.e., depending on C/P ratio, carriage stroke, and environmental influences, grease service life can range from a few hundred hours to several years. Typically, the maximum storage and operating period for lubricants is three to four years, as they undergo aging processes and become unusable after this period due to chemical changes. It is recommended to follow the lubricant manufacturer's instructions!

SCHNEEBERGER cannot guarantee that the calculated service life of SCHNEEBERGER MONORAIL guideways will be achieved through a single lubrication!

Without any subsequent lubrication, the service life of SCHNEEBERGER MONORAIL guideways will depend on the grease service life!

4.13.4 Precautionary Measures

SCHNEEBERGER MONORAIL guideways should be provided with sufficient lubricant according to application and environmental conditions. When selecting lubricants, we recommend contacting the lubricant manufacturer directly. Before using a lubricant, if you have no experience or have doubts about the lubricant manufacturer's statements, you should always check compatibility with the following:

- Other lubricants used

- Anti-corrosion agents

- Coolants

- Synthetic materials (elastomers and thermosetting plastics), such as seals, end plates

- Non-ferrous and light metals

Use of Coolants

If linear guideways are exposed to coolants, the lubricant may be washed away from the reservoir due to emulsification, which adversely affects guideway service life. Therefore, when using coolants, guideways should always be protected from direct contact with liquid media by protective covers. Compatibility of coolant with lubricant needs to be checked. Otherwise, subsequent lubrication intervals need to be shortened accordingly.

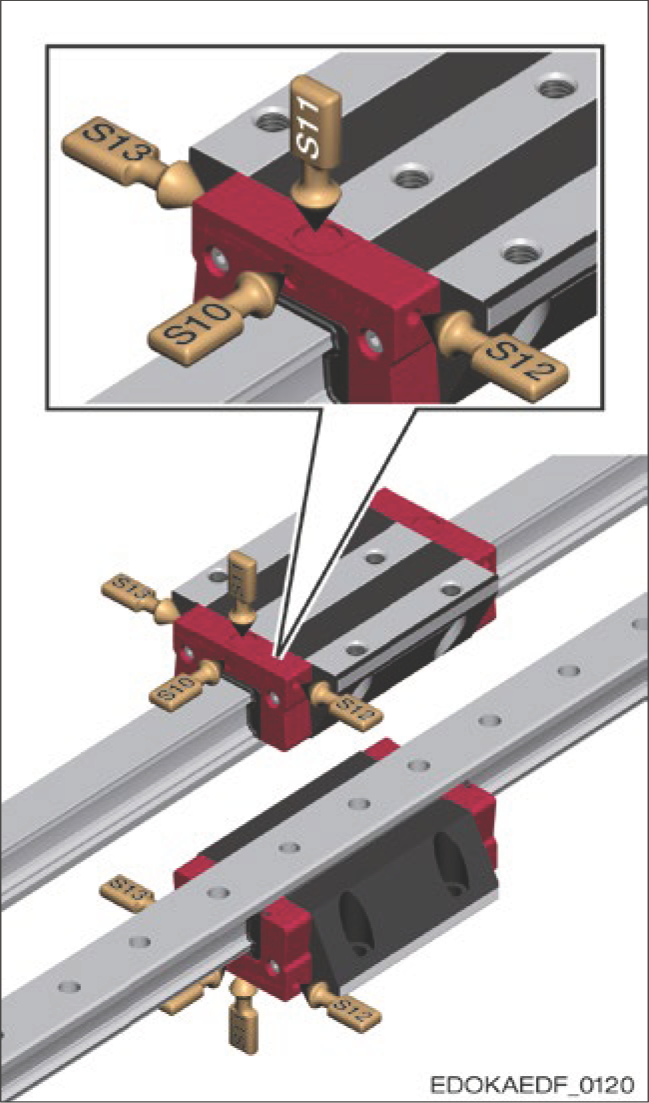

4.13.5 Lubrication Connections

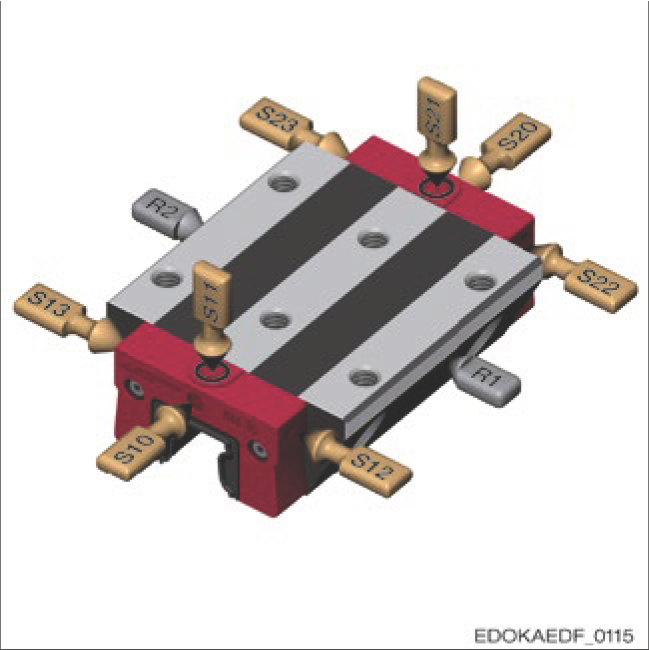

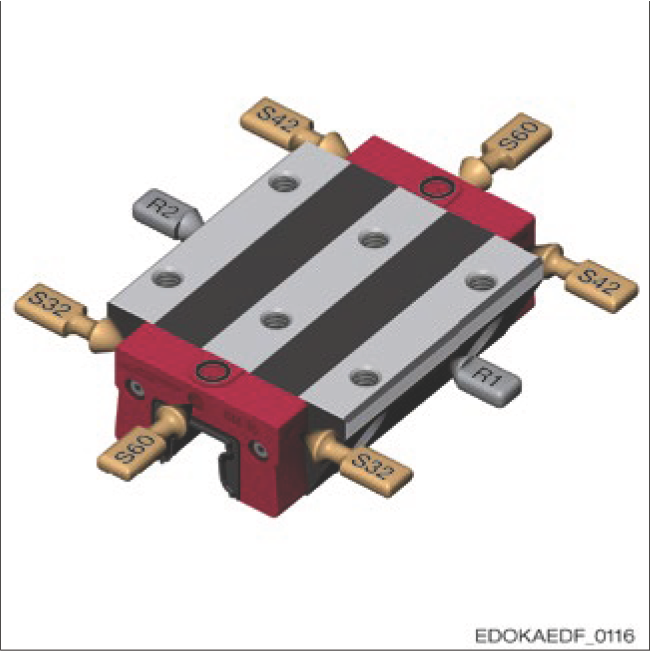

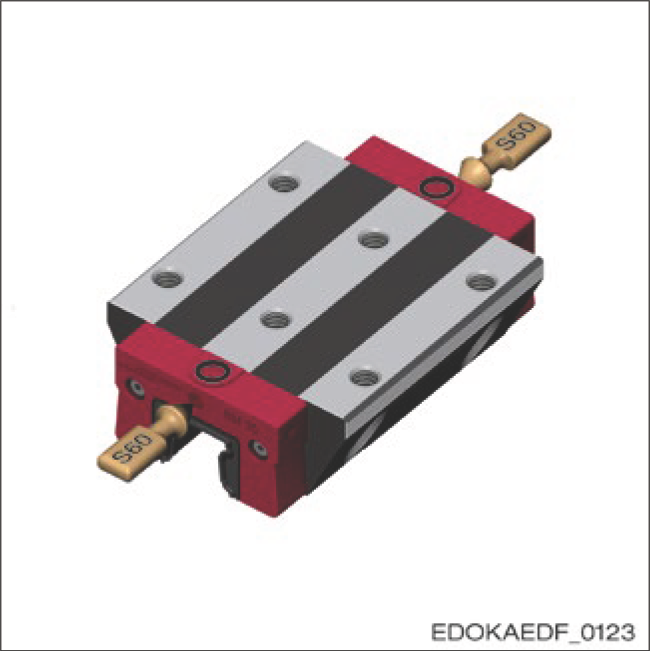

End plates have numerous lubrication connection options. This allows the lubricant supply to the carriage to be optimized according to structural design. Each lubrication port can be connected to a grease nipple or central lubrication system. As standard, all four tracks are lubricated through one connection. As a special feature for certain installation positions, the SCHNEEBERGER system provides independent lubrication on both sides of the carriage (S32, S42, and S60). This enhances guideway lubrication reliability, thereby extending machine service life. The position of lubrication connections is defined according to locating surface R1 as shown in the following images.

- When lubricating from above, an O-ring is inserted.

- All unused lubrication connections are closed with set screws.

Carriage lubrication connections for standard lubrication

R1 Locating surface, R2 Counter locating surface

Carriage lubrication connections for independent track lubrication

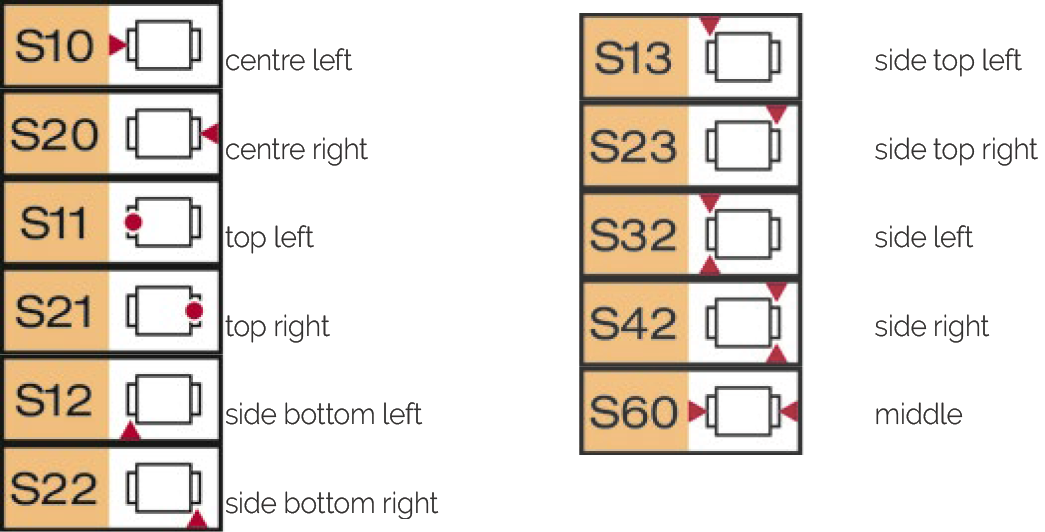

Lubrication connection positions: Center | Left | Upper left | Center | Right | Upper right | Upper left | Left | Upper right | Right | Side | Bottom left | Middle side | Bottom right

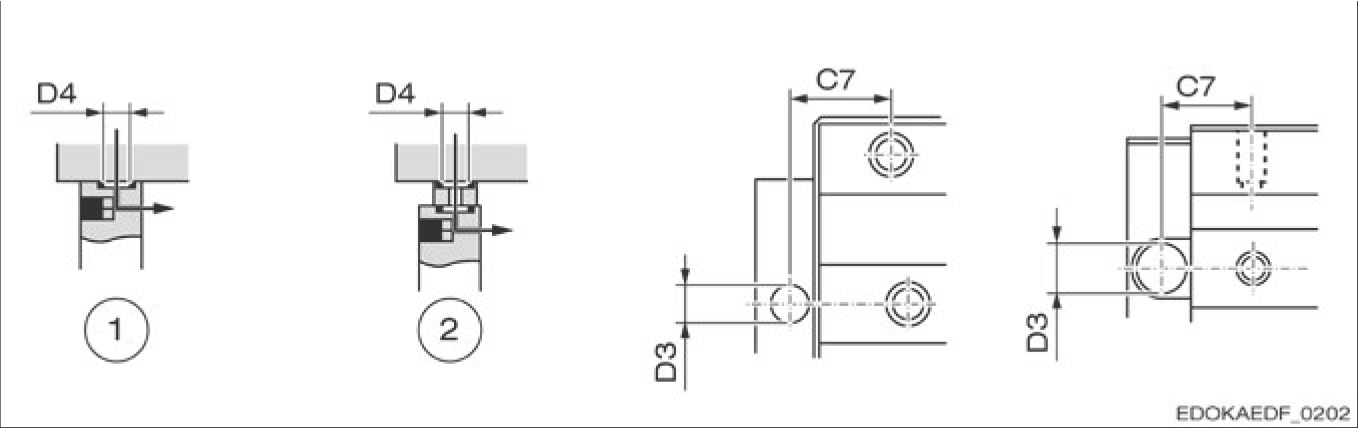

Lubrication Connections from Above

Lubrication can also be performed from above. The required position should be specified in the order. SCHNEEBERGER will perform the necessary machining.

Order details:

- Upper left -S11

- Upper right -S21

Lubrication connections from above:

- 1 - For MRA/MRB, BMA/BMB, BMC/BMD, BME, BMF/BMG

- 2 - For MRC/MRD, MRE

- D3 - Counterbore diameter

- D4 - Maximum diameter of lubrication fixing hole

- C7 - Spacing from fixing hole to lubrication fixing hole

(For detailed dimension tables, please refer to the complete product catalog or original documentation)

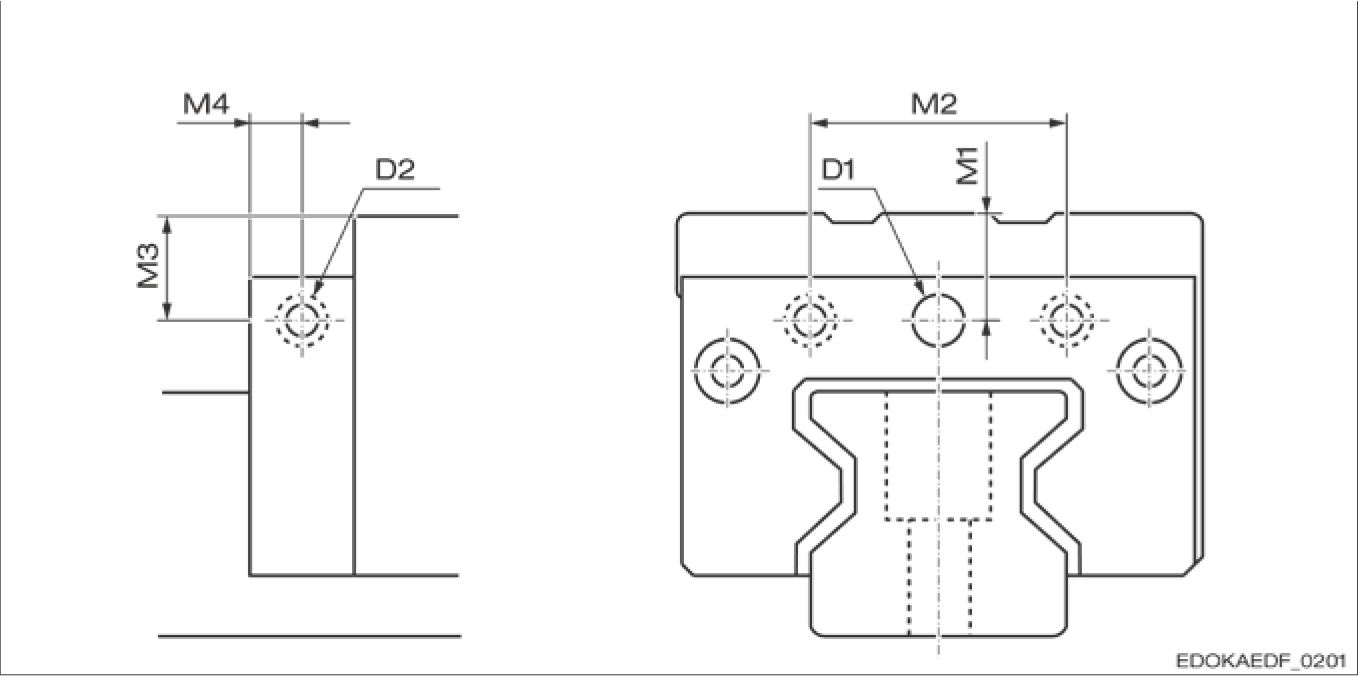

Connection Threads on Front and Side of End Plate

Connection threads on front and side of end plate:

- D1 Front connection thread diameter

- D2 Side connection thread diameter

- M1 End plate front lubrication spacing dimension

- M2* End plate front lubrication spacing dimension

- M3 End plate side lubrication spacing dimension

- M4 End plate side lubrication spacing dimension

- * Connection for optional lubrication facility

O-Rings

O-rings are required to seal lubrication connections. The table below shows O-ring dimensions for various carriage types.

| Type | D5 | × | D6 |

|---|---|---|---|

| BM 15 | 4.48 | × | 1.78 |

| BM 20, MR 25-55 | 6.75 | × | 1.78 |

| BM 25-45, MR 100 | 7.3 | × | 2.2 |

| MR 65 | 6.5 | × | 2 |

For deliverable standard lubrication options and order details, please refer to the SCHNEEBERGER MONORAIL and AMS product catalog. Sxx designation is required in the carriage order code. Other lubrication connection options for special individual cases are available upon request.

4.13.6 Grease Lubrication

SCHNEEBERGER recommends KP2K lubricating grease according to DIN 51825 or fluid grease GP00N and GP000N according to DIN 51826.

Initial Lubrication

Before commissioning, the carriage must be initially grease lubricated with the specified quantity as shown in the table below.

Note

- During the greasing process, the carriage needs to be moved back and forth several times on the guide rail, with a travel distance of 3 times the carriage length, or at least one carriage length in the case of bilateral lubrication.

| Carriage Type MR* | Initial Lubrication Grease Quantity (cm³) | ||||||

|---|---|---|---|---|---|---|---|

| MR 25 | MR 30 | MR 35 | MR 45 | MR 55 | MR 65 | MR 100 | |

| A, C, E, F | 1.9 | 2.2 | 2.9 | 5.5 | 9.1 | 15.5 | 32 |

| B, D, G | 2.2 | 2.8 | 3.8 | 6.9 | 11.2 | 20.2 | 40 |

| Carriage Type BM* | Initial Lubrication Grease Quantity (cm³) | |||||

|---|---|---|---|---|---|---|

| BM 15 | BM 20 | BM 25 | BM 30 | BM 35 | BM 45 | |

| A, C, E, F, H, L | 0.9 | 1.7 | 2.8 | 4.7 | 6.6 | 12.6 |

| B, D, G | 1.6 | 2.1 | 3.5 | 5.8 | 8.1 | 15.6 |

Subsequent Lubrication Quantity and Interval

Subsequent lubrication should be performed according to carriage load and external factors. Regardless of operating performance, we recommend re-lubrication at least every 3 months.

The lubricant quantity provided according to this interval can be obtained from the table below.

| Carriage Type MR* | Grease Quantity per Carriage (cm³) | ||||||

|---|---|---|---|---|---|---|---|

| MR 25 | MR 30 | MR 35 | MR 45 | MR 55 | MR 65 | MR 100 | |

| A, C, E, F | 0.4 | 0.8 | 1.1 | 2.1 | 3.2 | 5.9 | 13.6 |

| B, D, G | 0.5 | 0.9 | 1.3 | 2.4 | 4 | 7.4 | 17 |

Note

- The specified lubricant quantities and lubrication intervals are valid for both grease and fluid grease.

- The lubrication quantities for MONORAIL MR carriages also apply to AMSA 3B, AMSD 3B, and AMSABS 3B; the lubrication quantities for MONORAIL BM carriages also apply to AMSA 4B, AMSD 4B, AMSABS 4B, and BZ carriages.

4.13.7 Oil Lubrication

Initial Lubrication

Before commissioning, the carriage must be filled with the specified initial lubrication quantity. During this process, the total oil quantity should be injected in single pulses or multiple pulses within a short time while moving the carriage. The specified quantities apply to each carriage with one connection.

| Carriage Type MR* | Initial Lubrication Oil Quantity (cm³) | ||||||

|---|---|---|---|---|---|---|---|

| MR 25 | MR 30 | MR 35 | MR 45 | MR 55 | MR 65 | MR 100 | |

| Any installation direction | 0.3 | 0.45 | 0.6 | 0.9 | 1.4 | 2 | 2.3 |

Subsequent Lubrication Quantity and Interval

Subsequent lubrication should be performed according to carriage load and external factors. Subsequent lubrication interval = 30 km (v=1m/s, T=20-30°C).

| Carriage Type MR* | Oil Quantity (cm³) - Normal Installation Direction | ||||||

|---|---|---|---|---|---|---|---|

| MR 25 | MR 30 | MR 35 | MR 45 | MR 55 | MR 65 | MR 100 | |

| Normal installation direction | 0.15 | 0.2 | 0.25 | 0.35 | 0.5 | 0.7 | 1.2 |

4.13.8 Lubrication Requirements

Application Knowledge - Lubrication Requirements Under Special Operating Conditions

For linear guideway systems, the selection of lubrication systems is mainly influenced by application type and operating conditions. Specific applications impose specific requirements on lubrication.

- Lubricant type and lubricant properties

- Application method

- Position of lubrication joints

- Lubrication quantity and lubrication cycle

Installation Direction

In the case of grease lubrication, in any installation direction, it is ensured that all four tracks of the carriage can receive lubricant through one lubrication connection.

Installation Tilted Around Guide Rail Longitudinal Axis

When oil lubrication is provided or NLGI 000 grade fluid grease lubrication is used, and the installation is tilted around the guide rail longitudinal axis, special measures are required.

Carriage Type MR 25 - S60

- Separate lubrication

- 2 connections at front center of each carriage

Carriage Type MR 35-100 / BM 15-45 - S32/S42

- Separate lubrication

- 2 connections per carriage

Other Conditions

Coolants, high forces, high speeds, short strokes and vibration, long strokes, temperature, dirt, vacuum and other special conditions - please refer to the detailed catalog or consult SCHNEEBERGER.

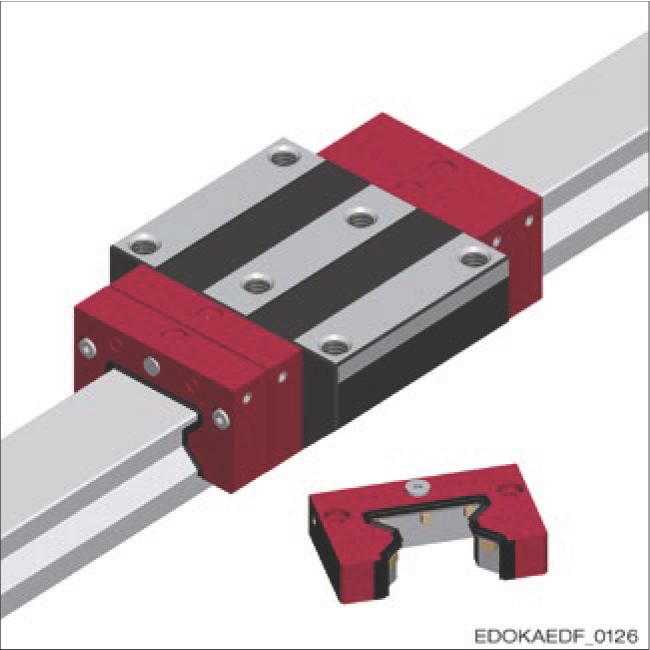

4.13.9 Lubrication Plate SPL

Carriage with lubrication plate SPL

Function and Application

Lubrication plates SPL have an integrated oil reservoir and are installed separately in front of the end plates on both sides of the carriage. They supply lubricant evenly to the rolling element tracks and guide rail upper surface over long periods through multiple contact points.

Subsequent Lubrication Quantity and Interval

Refilling of lubrication plates should be performed according to guideway load and other operating conditions. As a guideline, the following refill intervals can be assumed:

| Carriage Type | MR 25, BM 15-35 | MR 45-65, BM 45 |

|---|---|---|

| SPL | 2500 km | 5000 km |

When refilling lubrication plates, KLÜBER Lamora D 220 type oil should be used.