Depending on the application, the requirements for the SCHNEEBERGER MONORAIL guideway are different. This chapter details the technical characteristics of roller and ball guideways, main application areas, and performance comparison of the two guideway types to help you select the most suitable guideway system.

4.2.1 Characteristics

Depending on the application, the requirements for the SCHNEEBERGER MONORAIL guideway are different. The advantages of roller guideways are mainly suitable for applications requiring high load capacity and rigidity as well as extended service life, or applications with limited installation space.

Due to their lower moving mass, ball guideways have advantages in dynamic applications, in other words, at high speeds and accelerations or with increased requirements for noise accumulation and thrust. Otherwise, they have a cost advantage compared to roller types and can be optimally adapted to structural conditions due to their wider selection of structural shapes.

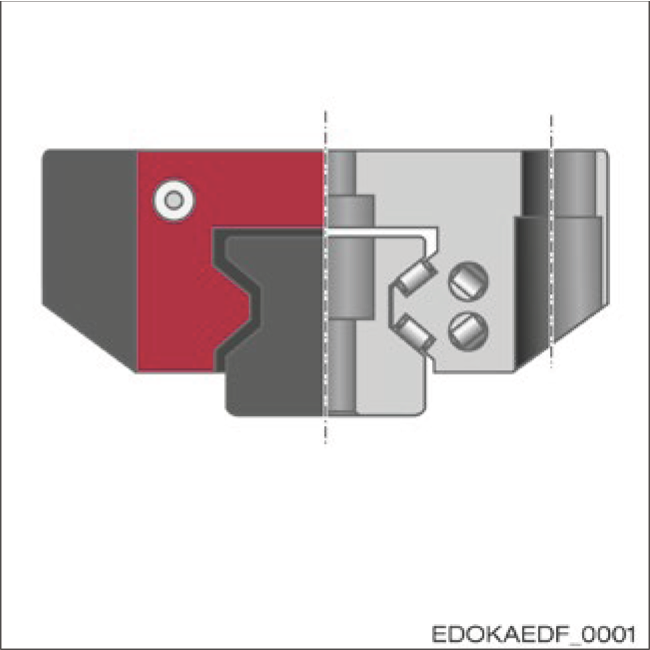

MONORAIL MR Roller Guideway

Technical Characteristics

- 4 raceways, O-type geometry, rollers with spherical surfaces

- Completely sealed carriage

- Main dimensions comply with DIN 645-1

- Wide range of design and lubrication options

- Numerous accessories for various applications

Main Application Areas

Machine tools with high cutting performance and extended service life, machines/equipment with very small installation dimensions, CNC machining centers, CNC lathes, CNC grinding machines, EDM machines, injection molding machines

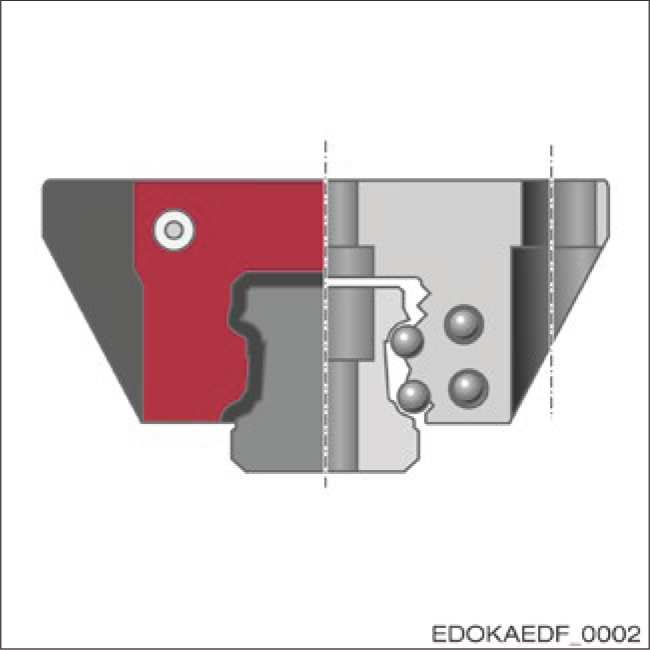

MONORAIL BM Ball Guideway

Technical Characteristics

- 4 rows of balls, O-type geometry, 2-point contact

- Optimized raceway geometry, reduced number of transition points

- Low number of parts

- Integrated lubrication grooves, reduced maintenance requirements

- Completely sealed carriage

- Trapezoidal guide rail profile with high rigidity and easy replacement of wear parts

- Main dimensions comply with DIN 645-1

Main Application Areas

Machine tools with small to medium cutting performance, secondary axes, woodworking machinery, sheet metal processing machinery, water jet/laser cutting systems, automatic punching machines, robotics, handling equipment and automation technology, electronics and semiconductor technology, measurement technology, medical technology

Characteristics Comparison

| Characteristic | MONORAIL MR Roller | MONORAIL BM Ball |

|---|---|---|

| Load capacity | ||

| Rigidity | ||

| Accuracy | ||

| Service life | ||

| Running characteristics/pulsation | ||

| Friction behavior | ||

| Permissible speed | ||

| Installation and maintenance | ||

| Accuracy and rigidity requirements for surrounding structure | High | Medium |

| Integrated distance measuring system | Yes | Yes |

| Integrated rack | No | Yes |

Note: • = Good, •• = Very good, ••• = Excellent, •••• = Outstanding

4.2.2 Fields of Application

Roller Guideways

Roller guideways are typically used for:

- Machine tools with high cutting performance and extended service life

- Machines/equipment with very small installation dimensions

- Machining centers

- Drilling centers

- CNC lathes

- CNC grinding machines

- EDM machines

- Injection molding machines

- Forming technology

Ball Guideways

Ball guideways are used for example in:

- Machine tools with small to medium cutting performance

- Secondary axes

- Woodworking machinery

- Sheet metal processing machinery

- Water jet and laser cutting systems

- Automatic punching machines

- Robotics

- Handling equipment and automation technology

- Electronics and semiconductor technology

- Measurement technology

- Medical technology

Selection Recommendation

When selecting guideway type, factors such as load capacity, speed, accuracy, and service life should be considered based on specific application requirements. Roller guideways are suitable for heavy load, high precision applications; ball guideways are suitable for applications with high speed and dynamic performance requirements. If in doubt, please consult the SCHNEEBERGER technical team.