Fastening Methods

Due to the compact structural form, the three main bearing types can be configured in a modular system with integrated assembly holes. AXDR double row angular contact roller bearings are particularly easy to assemble.

Standard Fastening Design

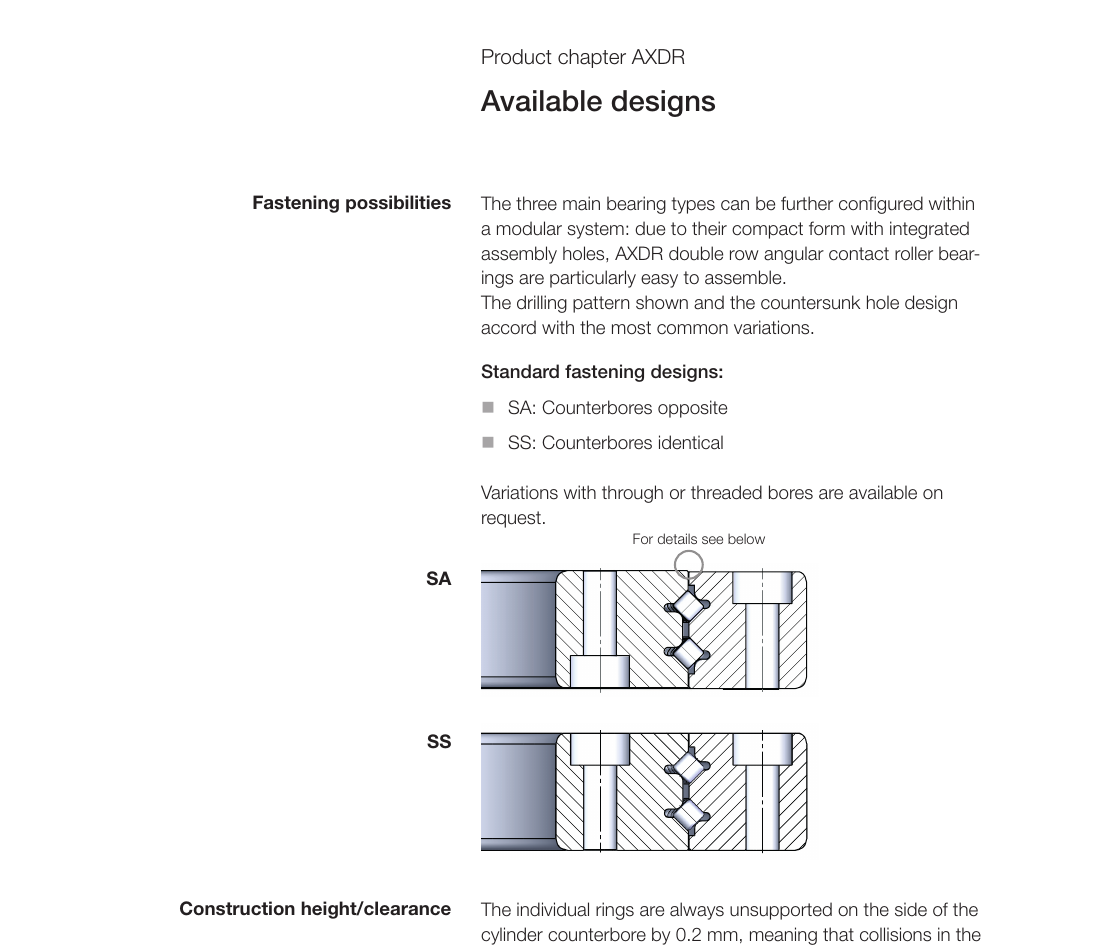

The drilling pattern and counterbore design shown represent the most common variants:

| Code | Design Name | Description |

|---|---|---|

| SA | Counterbores Opposite | Counterbores of inner and outer rings are on opposite sides |

| SS | Counterbores Identical | Counterbores of inner and outer rings are on the same side |

Other Variants: Variants with through holes or threaded holes can be provided on request.

Structural Height/Clearance

The individual ring is always unsupported on the cylindrical counterbore side with a counterbore depth of 0.2 mm, which means that the possibility of locking is excluded in fastening method "SA".

On the other hand, if ring configuration "SS" is selected, the total height is reduced by 0.2 mm because both recessed cylindrical counterbores are on the same side.

Seals

Double row angular contact roller bearings are equipped with non-rubbing gap seals. These seals reliably seal in normal environments without increasing friction torque.

Optional Seal Types

- NBR Seals - Increased sealing effect but generates additional friction at the seal contact surface

- Viton Seals - Resistant to high temperatures and chemicals

For oil or oil/air lubrication, seals can be adapted for controlled feed/discharge or distribution of lubricant in the bearing.

Accuracy Grades

AXDR bearings are supplied in the standard series with dimensional tolerance P5 acc. DIN 620. High-precision bore and outer diameter designs allow for precise fits and guidance, which is a major advantage in machine tools.

| Accuracy Grade | Description |

|---|---|

| Standard | P5 acc. DIN 620 dimensional tolerance |

| PRR50 | Restricted running accuracy (axial and radial runout tolerances limited) |

Running tolerances (axial and radial runout) are available in two grades: Standard and Restricted (PRR50). These approximately correspond to tolerances P2 and UP.

Other Tolerance Restrictions

Other tolerance restrictions can be provided on request. For example, height tolerance and offset tolerance can be defined in the same way as precise running torque.

Lubrication/Corrosion Protection

Initial filling uses high-performance grease from Li soap base mixed with synthetic hydrocarbon oil and mineral oil.

The grease is a special low-noise running grease with additives suitable for cylindrical roller bearing operation. Most conventional greases are not suitable for the operation of double row angular contact roller bearings and generate excessive friction, especially at higher speeds.

Avoid Over-filling

Overfilling of the bearing must be avoided. Excessive high-fat grease generates higher frictional heat, which must be limited during initial operation and subsequent re-lubrication.

We recommend oil lubrication for high-speed applications. myonic application engineering is happy to assist with more details and possible limit speeds.

Re-lubrication

Re-lubrication is performed through several radial lubrication channels in the outer ring. The position of lubrication channels in the inner ring's channels is listed under "Positioning Hole" in the product data sheet.

Bearings are supplied only with corrosion protection oil and marked with suffix L120. Fuchs Anticorit DF 19 is used as corrosion protection oil. This can be easily removed with most oils and greases.

Surface Treatment

myonic double row angular contact roller bearings are not supplied with surface treatment in the standard series.

Measuring System

AXDR bearings cannot be equipped with an installed measuring system.

For applications requiring measuring systems, we recommend using bearings from the AXRY-EX or AXRY-ES series, which can be equipped with incremental and absolute angle measuring systems.

Dimensions/Fixing Holes

All main dimensions such as bore diameter, outside diameter, bearing height, and fixing screws are identical to those of other manufacturers.

myonic AXDR double row angular contact roller bearings have further restricted standard tolerances to ensure raceway alignment and definition standards.

Main dimensions and fixing holes represent the most common sizes and define standards. If required, our application engineers are happy to provide further dimensions.

Rigidity Calculation

Rigidity calculation is performed under the following parameters:

- Radial and axial loads as well as tilting torque applied under axial preload conditions

- Light preload

- Normal surrounding structure and screw connection acc. to information in the production chapter

- Same FEM calculation procedure in all product groups using previously defined parameters

Rigidity Value Description

The rigidity values listed in the product tables can be directly compared (AXRY vs. AXDR vs. AXCR). Undersized, imprecise surrounding structures reduce rigidity at the bearing position, while on the other hand, rigidity can be increased through supported structures. myonic application engineering is happy to assist with further details or shaft optimization.

Limit Speed/Bearing Friction Torque

Limit Speed

The limit speeds shown in the dimension tables can be achieved under the following conditions: short-term continuous operation or under short-term continuous operation. If operating in the limit speed range for extended periods, the cooling system should dissipate any frictional heat generated by the bearing.

We recommend oil lubrication for high-speed applications. myonic application engineering is happy to assist with more details and possible limit speeds.

Friction Torque

The friction torque of double row angular contact roller bearings is particularly influenced by the selected preload. Higher preload leads to higher rigidity but also generates higher friction levels.

The selected lubricant (especially viscosity) and fill amount also have a direct influence on friction. Standard pre-lubricated bearings are suitable for short-term operation and short-term continuous operation up to limit speed.

Measuring System Best Suited

A measuring system is best suited for re-lubrication purposes. In the case of manual re-lubrication, there is a risk of overfilling, thereby increasing bearing friction torque.

During operation or re-lubrication, appropriate running-in periods must be observed. Specifications of surrounding structures and surrounding parts must be adhered to.

Axial and Radial Runout

Unseparated individual rings favor maximum radial runout and running accuracy. Narrower standard tolerances can be further restricted (suffix "PRR50").

myonic radial runout values include radial runout error of the raceway and roundness of the bore.