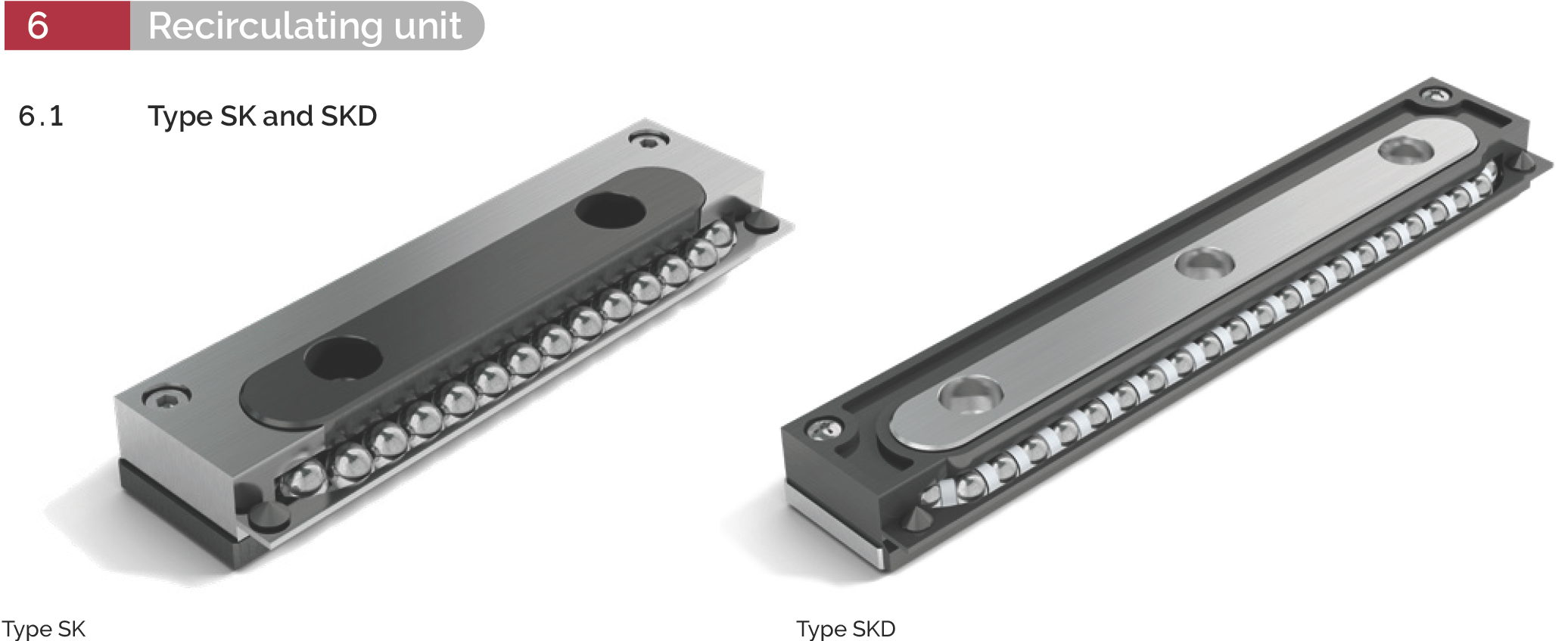

Type SK and SKD

The type SK recirculating unit is equipped with balls and is suitable for small to medium loads.

This recirculating unit is used combined with SCHNEEBERGER linear guideways of type R and/or RD. The SK units can be used in space saving designs that have equal loading in all directions.

Sizes 6 and 9 (size 12 on request) can additionally be equipped with damping elements (type designation SKD). These provide improved smoothness with slightly reduced load carrying capacity.

Benchmark Data

Supporting structure

- Precision hardened and ground

Materials

- Supporting structure made of through hardened tool steel, hardness 58 - 62 HRC

- Rolling element made of through hardened roller bearing steel, hardness 58 - 64 HRC

- Transfer units for sizes 1, 2, 9 and 12: anodised aluminium

- Transfer units for sizes 3 and 6: plastic or aluminium depending on length

- Non-corrosive version available on request

- Damping elements for SKD: plastic

- Scrapers: plastic

Scrapers

- From size 3, replaceable plastic track scrapers are standard

Velocity

2 m/s

Acceleration

50 m/s²

Operating temperatures

-40°C to +80°C

Compatibility

Compatible recirculating units

- SKC and SR

Compatible products

- Linear guideways type R and RD

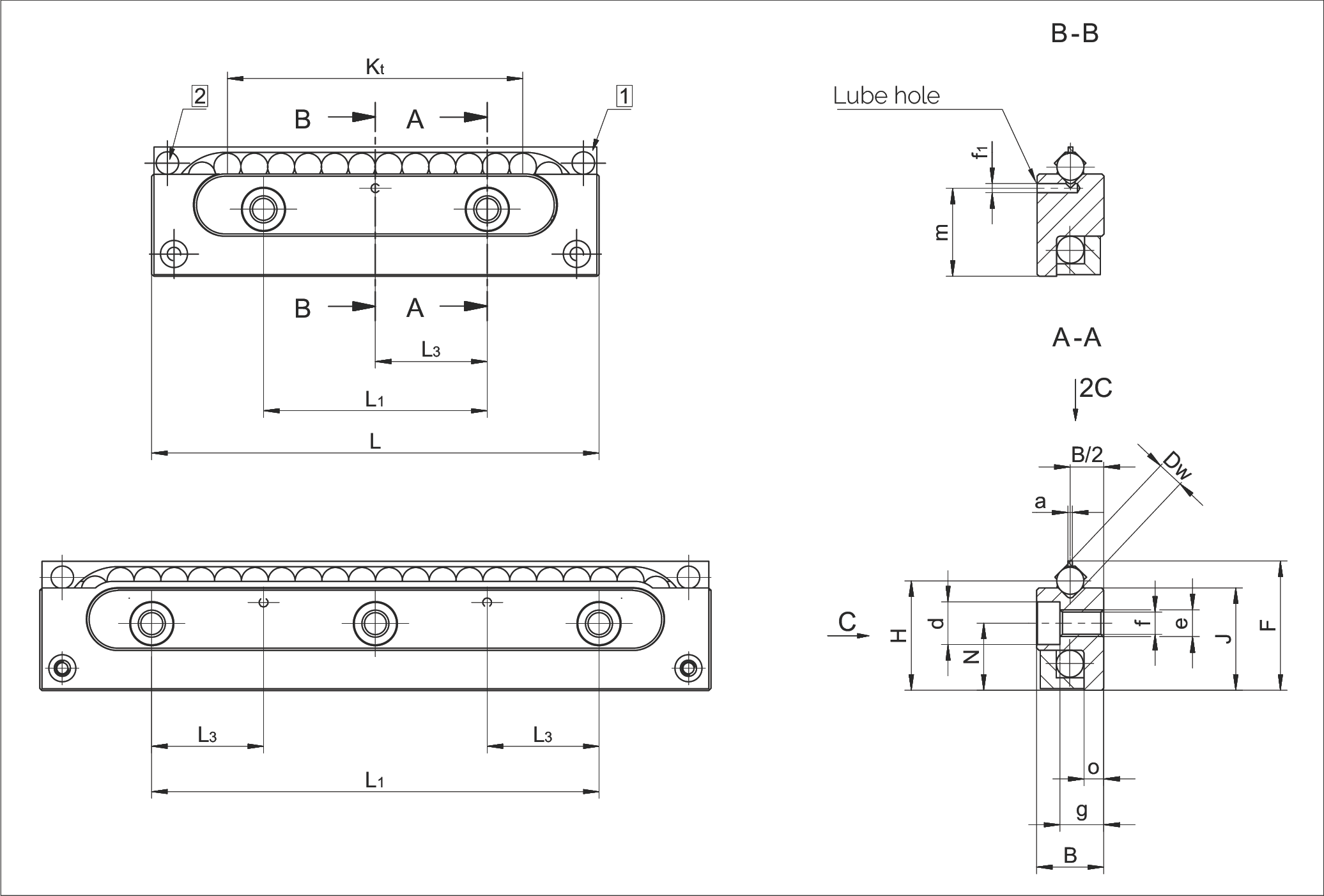

Dimensions and Load Capacities for Type SK and SKD

| Type and Size | Weight (g) | Dimensions (mm) | C (N) | Options (see chapter 8) | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | Dw | F | H | J | Kt | L | L1 | L3 | N | a | d | e | f | f1 | g | m | o | SK | SKD | |||

| SK 1-022 | 5 | 4 | 1.5 | 8.4 | 7.25 | 6.9 | 9 | 22 | 10 | - | 4.8 | 0.3 | 3 | M2 | 1.65 | - | 2.6 | - | 1.2 | 63 | - | GP |

| SK 2-032 | 10 | 6 | 2 | 11 | 9.5 | 9 | 16 | 32 | 15 | - | 6 | 0.3 | 4.4 | M3 | 2.55 | - | 4 | - | 1.9 | 135 | - | GP |

| SK 3-075 | 45 | 8 | 3 | 16.9 | 14.5 | 13.8 | 48 | 75 | 25 | 12.5 | 9 | 0.5 | 6 | M4 | 3.3 | 1.5 | 4.9 | 11.5 | 2.4 | 425 | - | GP |

| SK 6-100 SKD 6-100 | 200 | 15 | 6 | 28.9 | 24.5 | 22.9 | 60 | 100 | 50 | 25 | 15 | 1 | 9.5 | M6 | 5.2 | 2 | 9.8 | 19.7 | 4.4 | 715 | 650 | GP |

| SK 6-150 SKD 6-150 | 300 | 15 | 6 | 28.9 | 24.5 | 22.9 | 102 | 150 | 2×50 | 25 | 15 | 1 | 9.5 | M6 | 5.2 | 2 | 9.8 | 19.7 | 4.4 | 1,170 | 1,100 | GP |

| SK 9-150 SKD 9-150 | 670 | 22 | 9 | 45.1 | 39 | 36.7 | 90 | 150 | 100 | 50 | 26 | 1.5 | 10.5 | M8 | 6.8 | 3 | 15.8 | 32.4 | 6.3 | 1,650 | 1,500 | GP |

| SK 9-200 SKD 9-200 | 940 | 22 | 9 | 45.1 | 39 | 36.7 | 144 | 200 | 100 | 50 | 26 | 1.5 | 10.5 | M8 | 6.8 | 3 | 15.8 | 32.4 | 6.3 | 2,550 | 2,400 | GP |

| SK 12-2001) SKD 12-2001) | 1,470 | 28 | 12 | 57.1 | 49 | 45.9 | 120 | 200 | 100 | 50 | 32 | 2 | 13.5 | M10 | 8.5 | 3 | 19.8 | 40.2 | 7.7 | 2,860 | 2,600 | GP |

Notes:

- 1) SK 12 and SKD 12 are only available on request

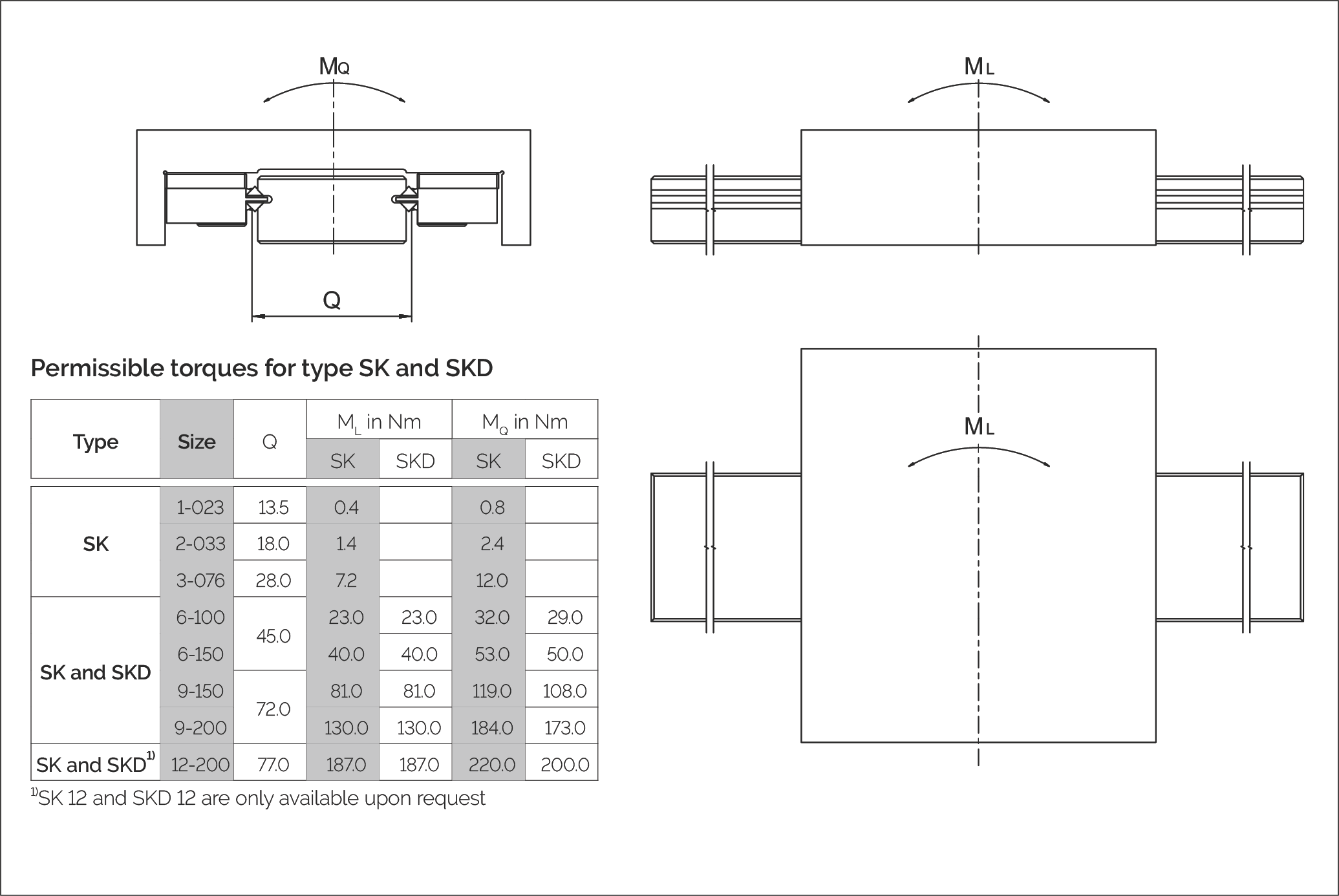

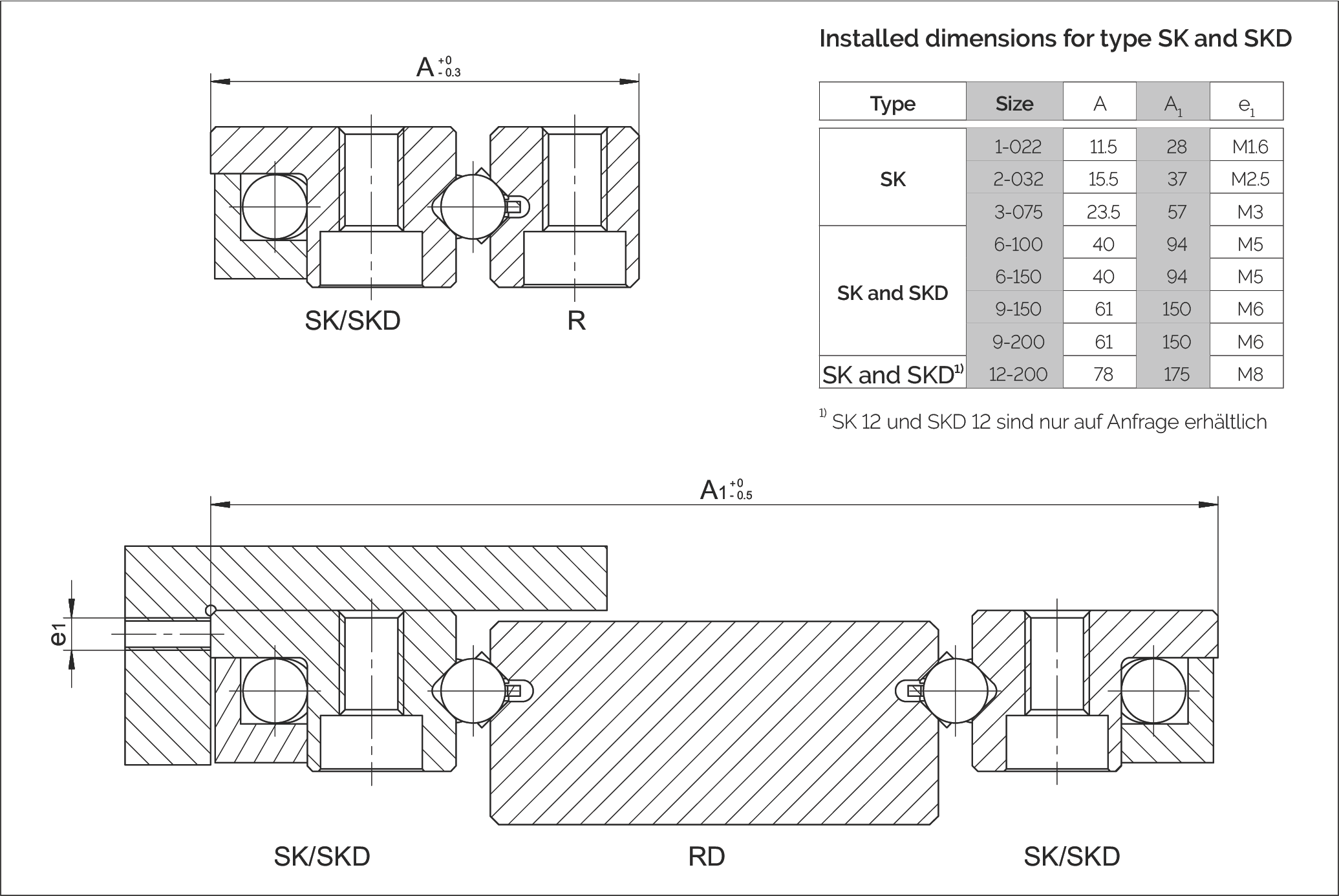

Installation Dimensions and Permitted Torques for Type SK and SKD

Installation Dimensions

Permitted Torques