Mineral Casting for Optimum Performance

Whether they are light 80 gram units or weigh in at 30 tonnes, our products offer clear benefits for our customers.

Mineral casting has been used for many years as an alternative to cast iron and steel structures, and is now the preferred technology for a wide range of applications. The use of mineral casting means that our customers have decisive advantages when manufacturing machine tools, handling systems and measuring equipment.

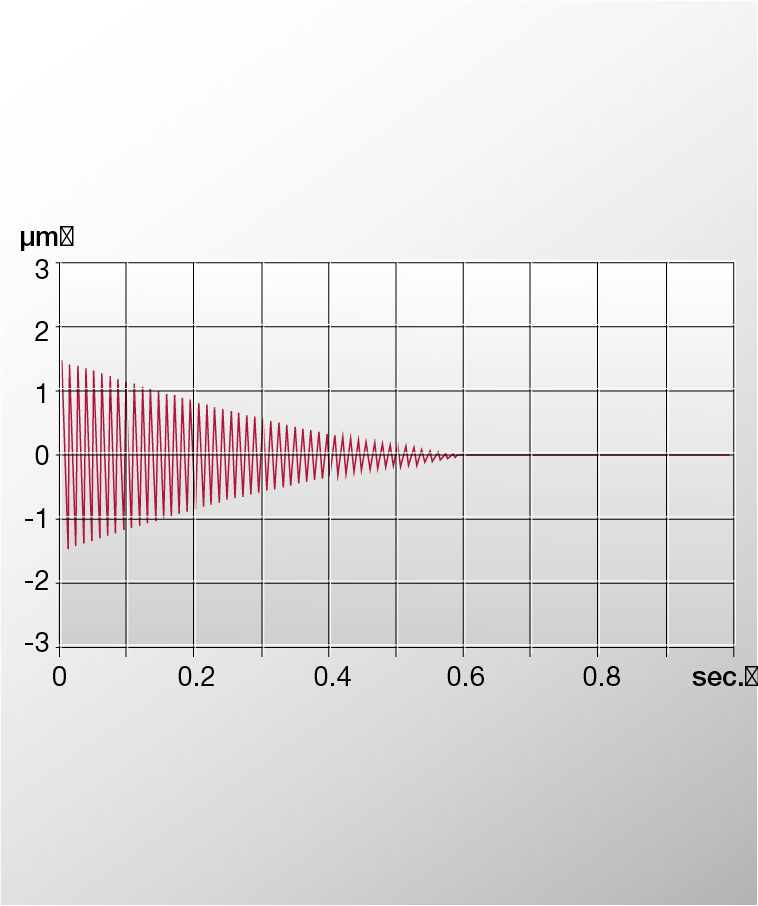

1. Superior Vibration Damping

Higher speeds and greater precision

The damping offered by Schneeberger's mineral casting is up to 10 times better than that offered by steel or cast iron. This provides extremely high dynamic stability for the machine structure. As a result, higher machining speeds and greater precision can be achieved compared to machines made from conventional materials.

Excellent vibration damping for maximum speed

2. A Combination of Cost-Effectiveness and Precision

Cast directly to final dimensions

In many instances, the mineral cast components are cast to the final dimensions because virtually no contraction takes place during hardening – or it is compensated for immediately. We use the latest technology to produce challenging high-accuracy surfaces.

Precision – right through to quality control

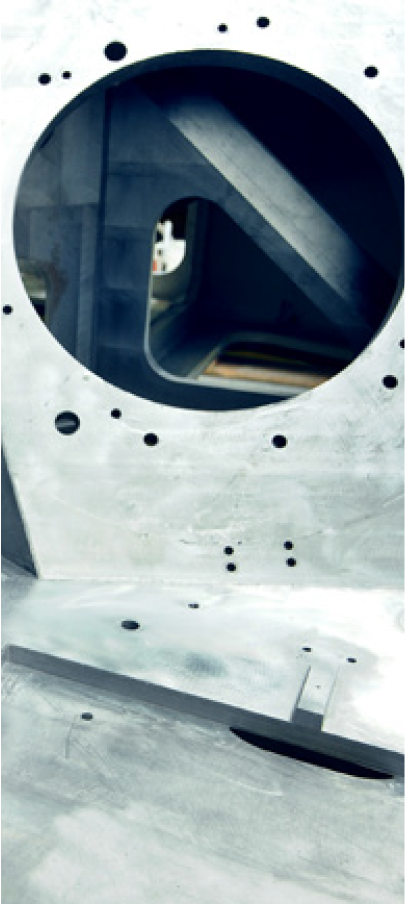

3. Flexible Shaping

For a wide range of products

Our mineral casting technology provides an exceptional degree of freedom with respect to the shape of the components. The material's specific characteristics even allow for unconventional processes such as bonding, which in turn allows complex product structures to be produced.

Exceptional flexibility in terms of shape

Parts and systems can be simply cast using mineral casting

4. Casting for Parts and Systems

Advantages of cold casting process

Our mineral casting construction technique uses a cold casting process. This makes it simple for us to cast additional components and connections to services into the construction, and also to do the same for sensors and measurement systems. Each part that we integrate into the mineral casting shortens the processing times for our customers, which in turn saves them valuable fitting time.

5. Significantly Less CO₂ and Reduced Energy Consumption

Blue Competence®

Schneeberger Mineralgusstechnik fully supports the «Blue Competence» campaign, an energy and environmental initiative led by the VDW (the German Machine Tool Builders' Association).

The cold casting process means that mineral casting does not need any additional heat energy during the manufacturing process. The heat is created by an exothermic reaction between the chemical components. As a result, mineral casting uses less energy and has a better carbon footprint than can be achieved by alternative technologies such as steel and cast iron.

And as an additional environmental bonus, our mineral castings can be fully recycled. When our customers have finished using their mineral casting parts, they can return the products to us and we work with fully certified companies to recycle the material.

Excellent energy efficiency thanks to our cold casting process

Five Key Benefits Overview

Vibration Damping

Up to 10 times better damping than steel or cast iron

Cost-Effectiveness

Virtually no shrinkage, cast directly to final dimensions

Flexible Shaping

Exceptional freedom in shape, supports unconventional processes

System Integration

Cold casting allows easy embedding of components and connections

Eco-Friendly

Blue Competence certified, fully recyclable