About Gear Racks

The main characteristic of gear rack drive systems is their high efficiency. They are the optimal choice for applications with high axial forces.

This drive rigidity remains constant over the entire length.

For long strokes exceeding 2 meters, gear rack drives are also very cost-effective.

In a rack and pinion system, the slide is driven by a pinion running on a fixed gear rack.

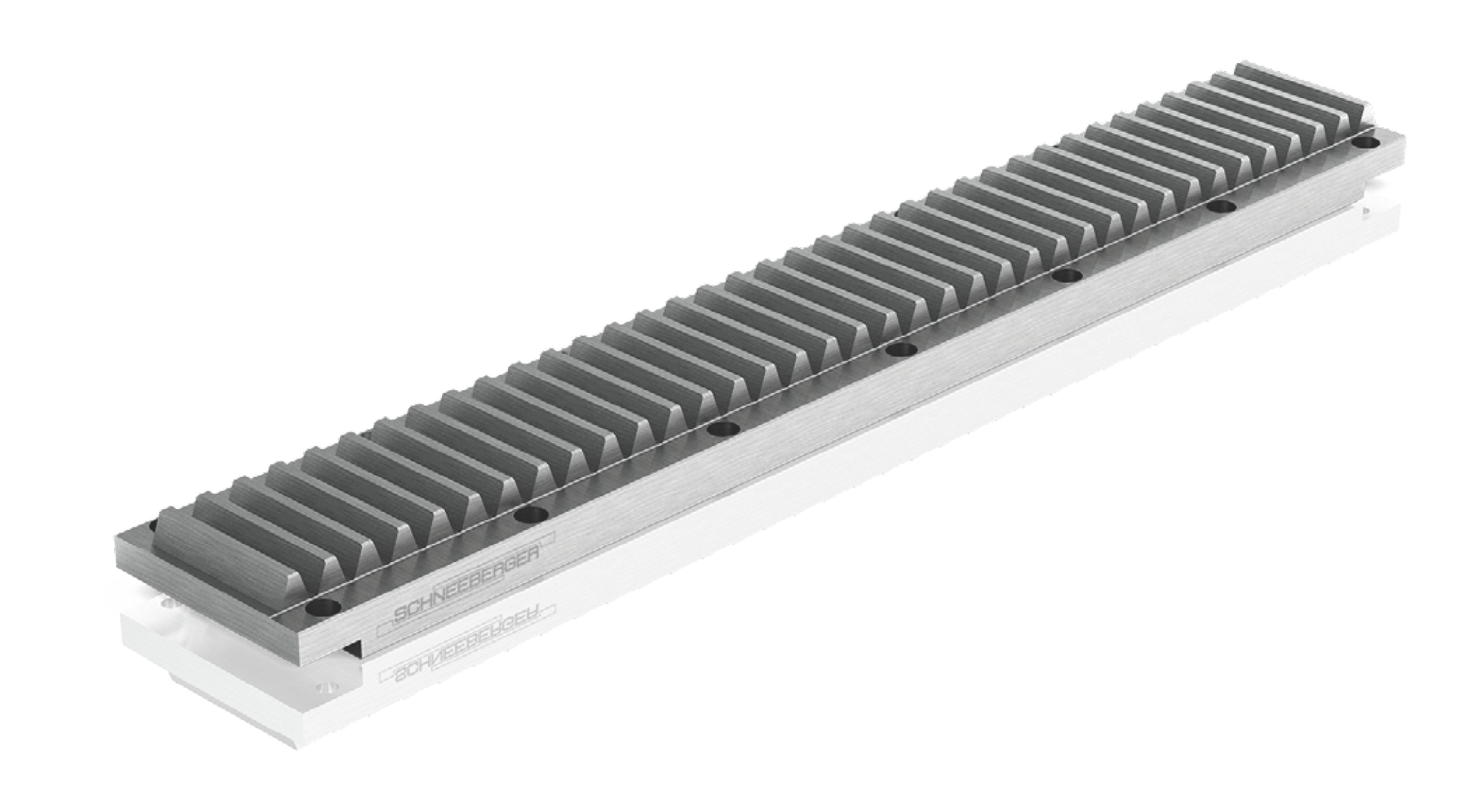

There is a fundamental difference between straight-toothed and helical gear racks. In addition to typical dimensions, SCHNEEBERGER offers any cross-section with metric pitch or module pitch. The maximum single-piece length is 3000 mm. Longer lengths can be connected via butt joints.

Gear racks can be milled or ground according to customer requirements. A special feature is the ability to use different materials and hardening processes. Depending on the required load, you can choose from soft, induction hardened, case hardened, or nitrided gear racks.

Standard Gear Racks

Straight-toothed and helical gear racks are available in typical industrial sizes from module 2 to module 12. Different materials, hardness levels, and precision grades are available depending on the required load.

Straight Gear Racks

For general industrial applications, easy to install and maintain

View Specifications →Stainless Steel Gear Racks

For special environments requiring corrosion resistance

View Specifications →Customised Gear Racks

Do you need gear racks but the standardised dimensions don't fit your system? No problem.

You can get any gear rack up to module 20. The maximum single-piece length is 3000 mm.

Customers can choose from different materials, so gear racks can be configured as required.

Special is our standard.

Learn about customised gear racks →