4.14.1 Standard Seals

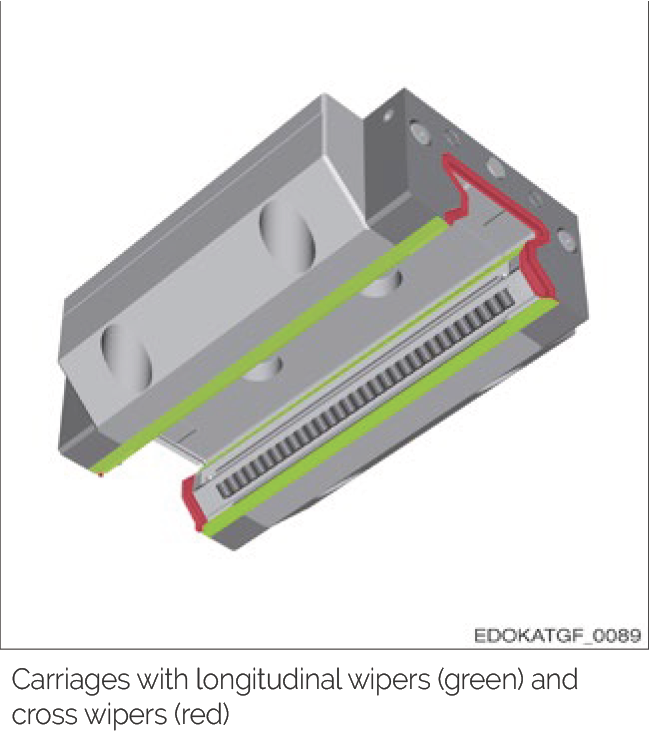

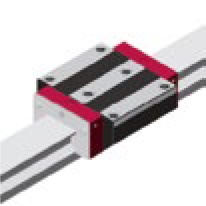

Carriages of SCHNEEBERGER MONORAIL guideways are equipped as standard with double-lip end wipers and two top and bottom longitudinal wipers on each side. These sealing elements provide effective sealing to prevent contaminants from entering and minimize lubricant loss, thereby extending guideway service life.

Carriage equipped with longitudinal wipers (green) and end wipers (red)

MONORAIL BM Wiper Variants

MONORAIL BM ball guideways are often used in applications with lower contamination levels but requiring low thrust. Therefore, in addition to standard end wipers, these guideways also offer special low-friction wipers, as well as wiper-free options for cleanroom applications.

Standard Wiper

Wiper Type: Standard wiper

Order Code: QN

Application: General industrial environments

Low-Friction Wiper

Wiper Type: Low-friction wiper

Order Code: QL

Application: Low contamination environments, low thrust required

Without End Wipers

Wiper Type: Without end wipers

Order Code: Q0

Application: Cleanroom environments

Important: Correct sealing system selection is critical for guideway system reliability and service life. Please select the appropriate wiper type according to your specific application conditions.

4.14.2 Additional Wipers

For special operating conditions such as heavy dust accumulation, chip deposits, or coolant environments, SCHNEEBERGER provides additional seals that are installed in front of the carriage to provide additional mechanical protection.

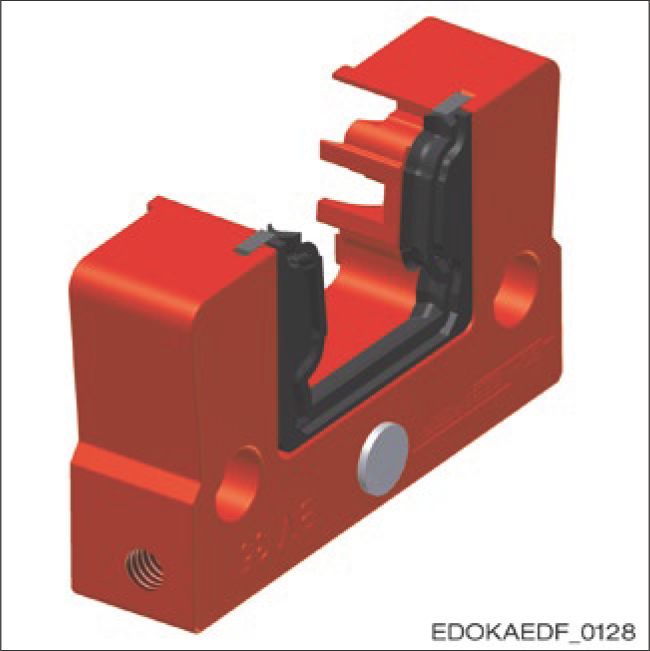

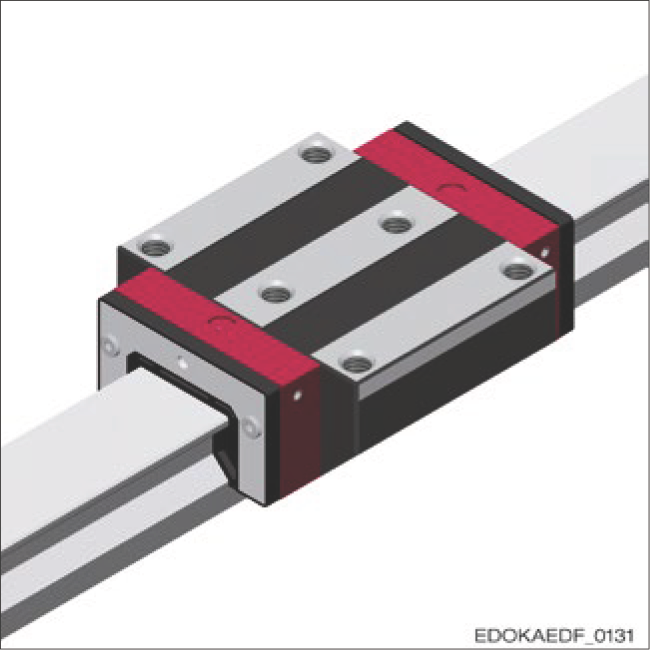

NBR Additional Wipers

NBR (nitrile rubber) additional wipers provide extra protection for carriages in heavily contaminated environments. They consist of a load plate with a very robust single-lip seal installed on it. Due to the flexibility of the wiper, which can be pushed over the guide rail cross-section, it can be retrofitted without removing the carriage from the guide rail.

NBR additional wipers are available for all MR and BM carriage types. Order code is "ZBN xx" for BM carriages and "ZCN xx" for MR carriages, where "xx" represents the size.

Carriage equipped with NBR additional wiper

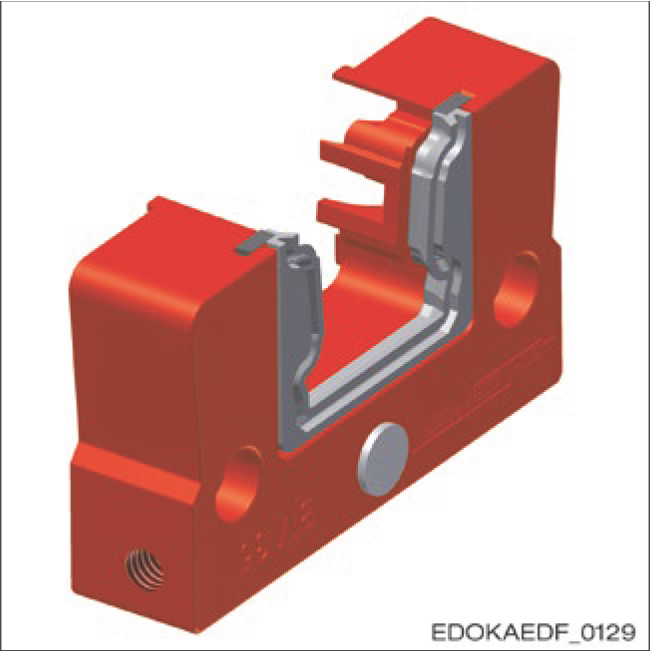

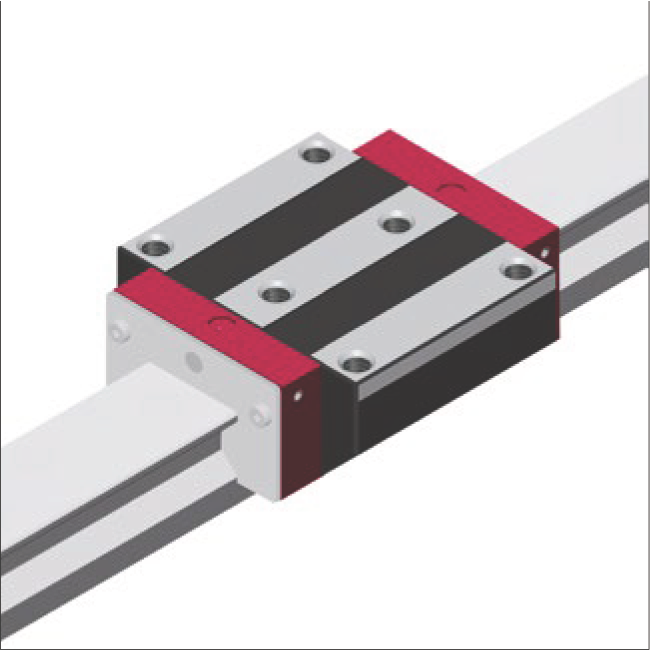

Viton Additional Wipers

Similar to NBR wipers, Viton additional wipers provide extra protection for carriages in heavily contaminated environments. However, they are also suitable for applications with corrosive coolants, as Viton® (fluorinated rubber) is chemically resistant and exhibits high temperature resistance. Due to the flexibility of the wiper, which can be pushed over the guide rail cross-section, it can also be retrofitted without removing the carriage from the guide rail.

Carriage equipped with Viton additional wiper

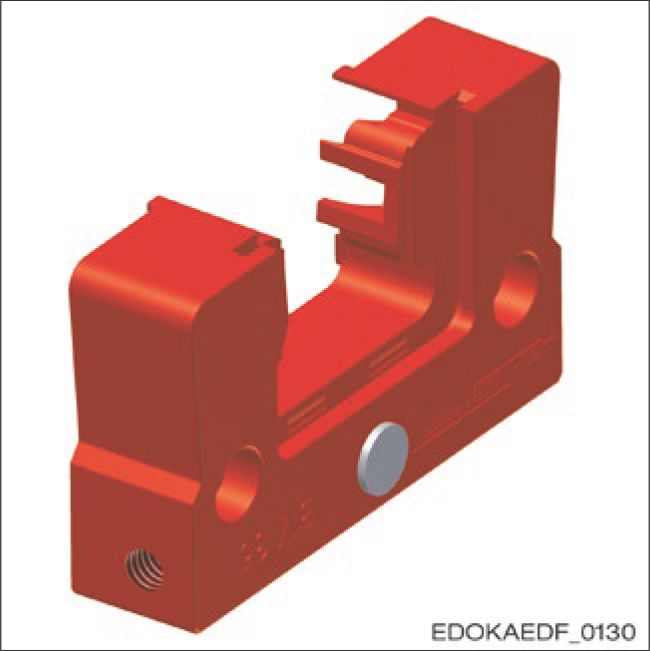

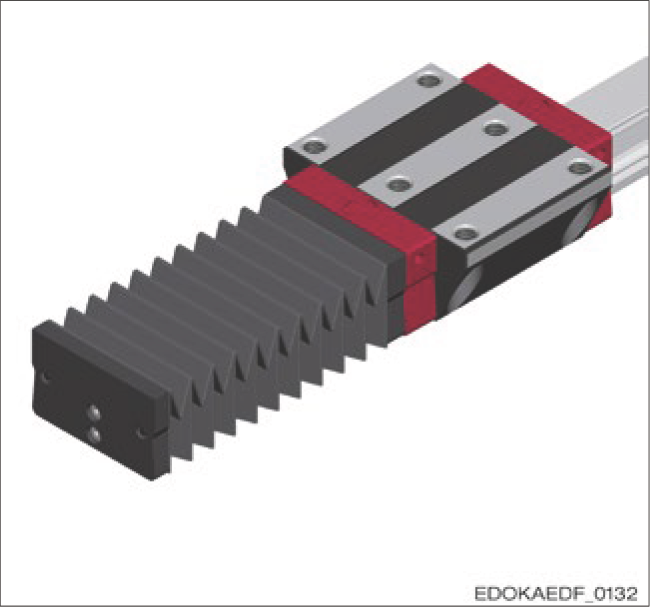

Metal Wipers

Metal wipers are made of stainless steel and are used to protect the sealing lips and additional wipers of the carriage from hot chips. Large and loose dirt particles are pushed away and do not get stuck due to the larger radial clearance from the guide rail. Specially adapted types are available for guide rails using the AMS measuring system.

Carriage equipped with metal wiper

Installation Note: Metal wipers and additional wipers can be used in combination. They can also be combined with lubrication plate SPL.

4.14.3 Bellows

Bellows are mainly used as an additional form of protection for carriages against dust and splashing water.

They are available in a standard design for MONORAIL MR roller guideways and MONORAIL BM ball guideways. The bellows are made of synthetic fabric coated with plastic on both sides. They extend over the entire length of the guide rail, and their cross-section matches the corresponding end plates on the carriage.

Order code is "FBB" for all BM carriages sizes 20-45, and "FBM" for all MR carriages sizes 25-65.

Carriage equipped with bellows

Caution

Component damage due to improper structure

- When using bellows, it is important to ensure that due to any vacuum that may occur during movement, dirt is not drawn under the bellows.

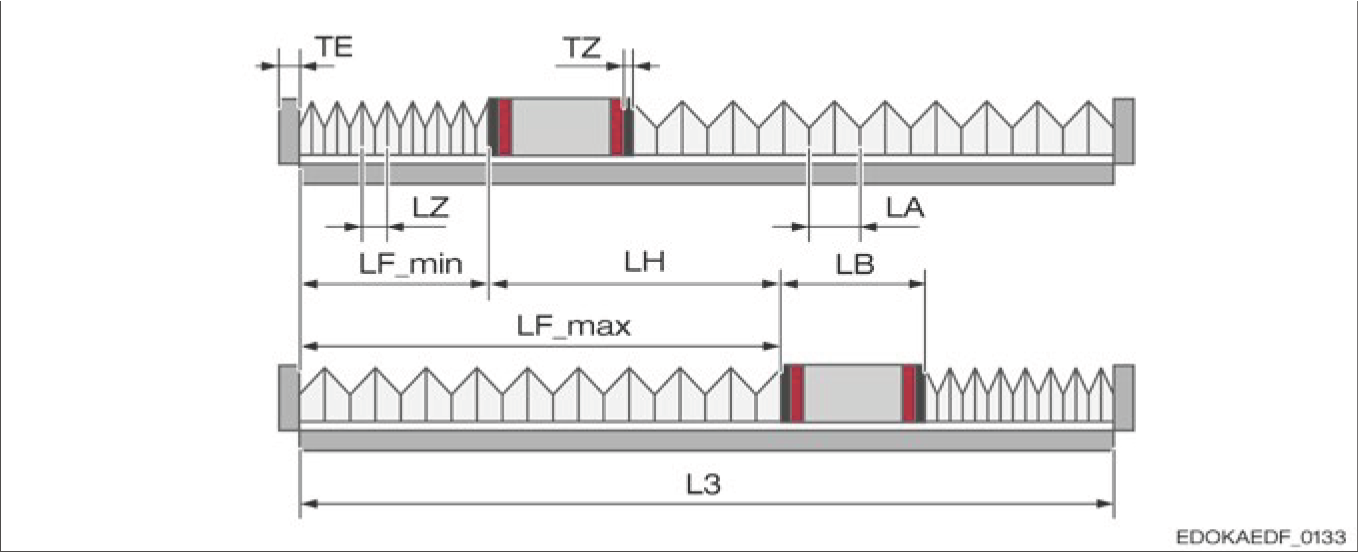

Calculating Length

Guide rail length for one carriage

Length for one guide rail with one carriage:

| Symbol | Description |

|---|---|

| LB | Total length with adapter plate |

| LH | Stroke |

| LF_min | Bellows compression |

| LF_max | Bellows extension length |

| L3 | Guide rail length |

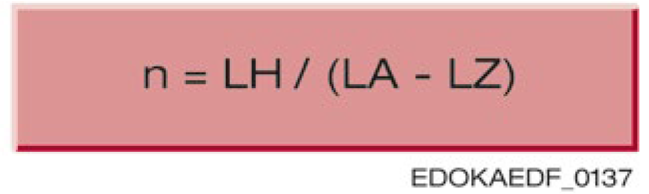

Number of folds (n) per bellows - between carriage and guide rail end

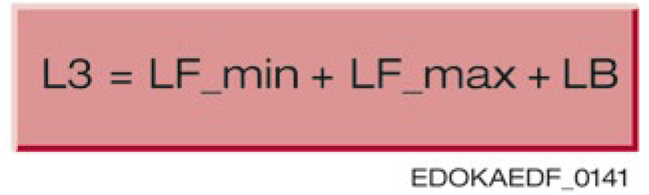

Guide rail length L3

For detailed dimension data, please refer to the complete product catalog.

4.14.4 Sealing Application

The following chart provides an overview of different seal types, their characteristics, and applicable application areas.

| Operating Conditions | Seal Type | |||||

|---|---|---|---|---|---|---|

| Without End Wipers Q0 | Low-Friction Wiper¹ QL | Standard Wiper QN | NBR Additional Wiper ZBN | Viton Additional Wiper ZBV | Metal Wiper² | |

| Cleanroom environment | ●●● | ●●○ | ●○○ | ○○○ | ○○○ | ○○○ |

| Low contamination environment | ●●○ | ●●● | ●●● | ●●○ | ●●○ | ●○○ |

| General industrial environment | ●○○ | ●●○ | ●●● | ●●● | ●●● | ●●○ |

| High contamination environment | ○○○ | ○○○ | ●●○ | ●●● | ●●● | ●●● |

| Coolant environment | ○○○ | ○○○ | ●●○ | ●●● | ●●● | ●●● |

| Chemical corrosion environment | ○○○ | ○○○ | ●○○ | ●●○ | ●●● | ●●○ |

| High temperature environment (>80°C) | ○○○ | ○○○ | ●○○ | ●○○ | ●●● | ●●● |

| Low thrust requirement | ●●● | ●●● | ●●○ | ●○○ | ●○○ | ○○○ |

Suitability Rating:

- ●●● = Very suitable

- ●●○ = Suitable

- ●○○ = Limited suitability

- ○○○ = Not recommended

Notes:

- ¹ Only for BM series

- ² Special order, consult SCHNEEBERGER

Sealing System Visual Comparison

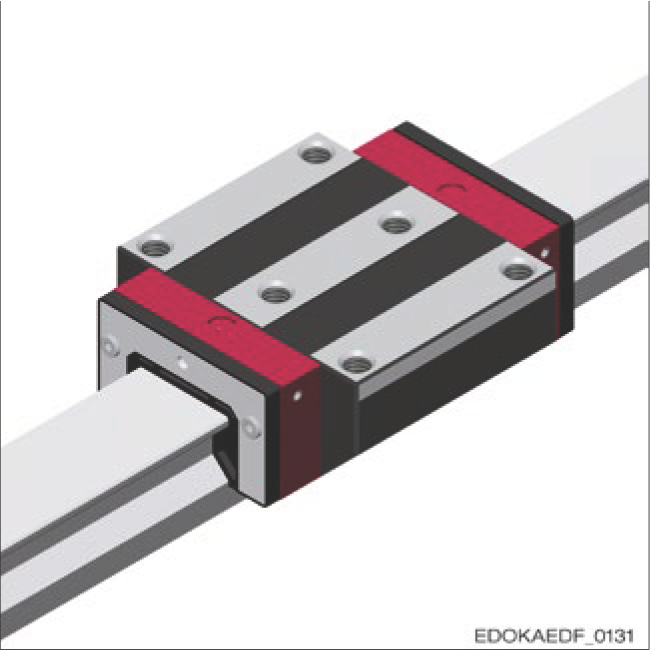

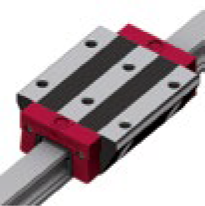

Without End Wipers (Q0)

Cleanroom applications, lowest thrust

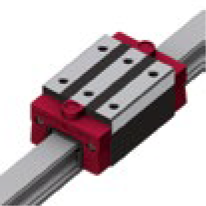

Low-Friction Wiper (QL)

Low contamination environments, low thrust

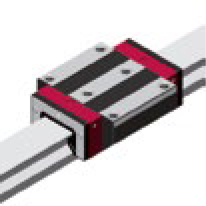

Standard Wiper (QN)

General industrial applications

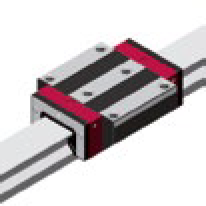

NBR Additional Wiper

High contamination and coolant environments

Viton Additional Wiper

High temperature and chemical corrosion environments

Metal Wiper

Extreme contamination environments

Sealing System Performance Comparison Chart