In every linear guideway, the slide can shift from the center position along the longitudinal axis. Slide creep reduces optimal load distribution and requires correction strokes to return the slide to the center position. Correction strokes consume significant energy.

Causes of Slide Creep

- High acceleration and speed

- Vertical installation of guideways

- Uneven load distribution

- Overhanging slides

- Different coefficients of thermal expansion

- Design and installation (insufficient rigidity and/or precision of connecting structure)

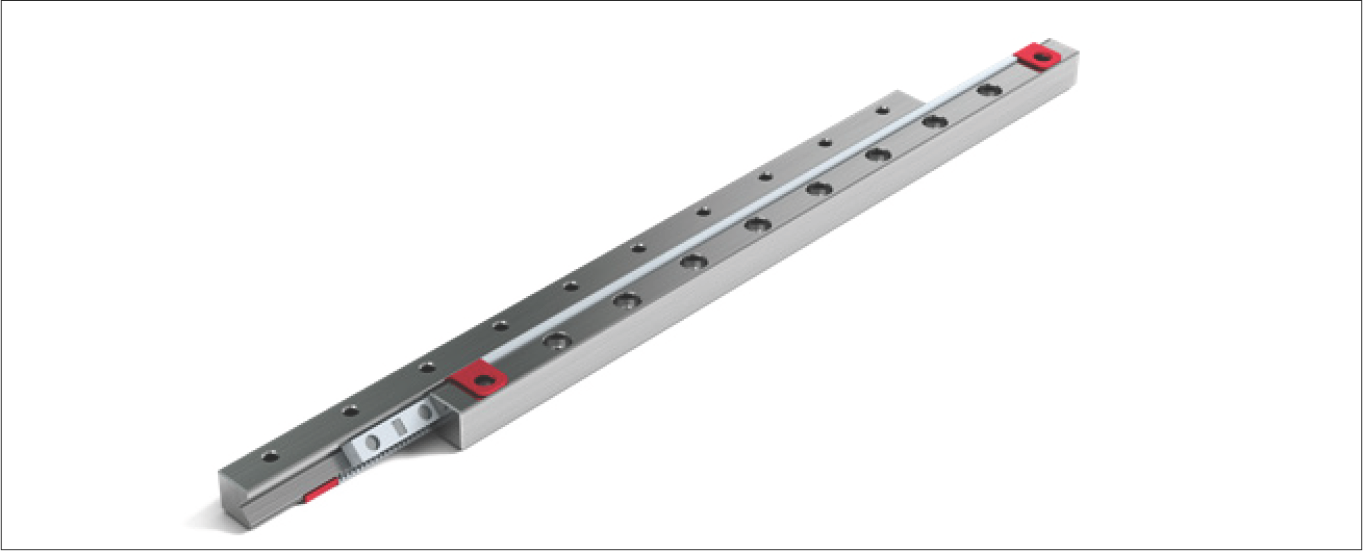

Advantages of FORMULA-S

- No slide slippage, therefore consistent load conditions

- Avoids correction strokes

- No slide return force required

- Acceleration up to 300 m/s² (30 g)

- Speed 1 m/s

- Easy to install and/or remove

- Extended service life

- Vacuum compatibility up to 10⁻⁷ mbar

Applicable Guideways

- RN 3, RN 4 and RN 6

- RNG 4, RNG 6 and RNG 9

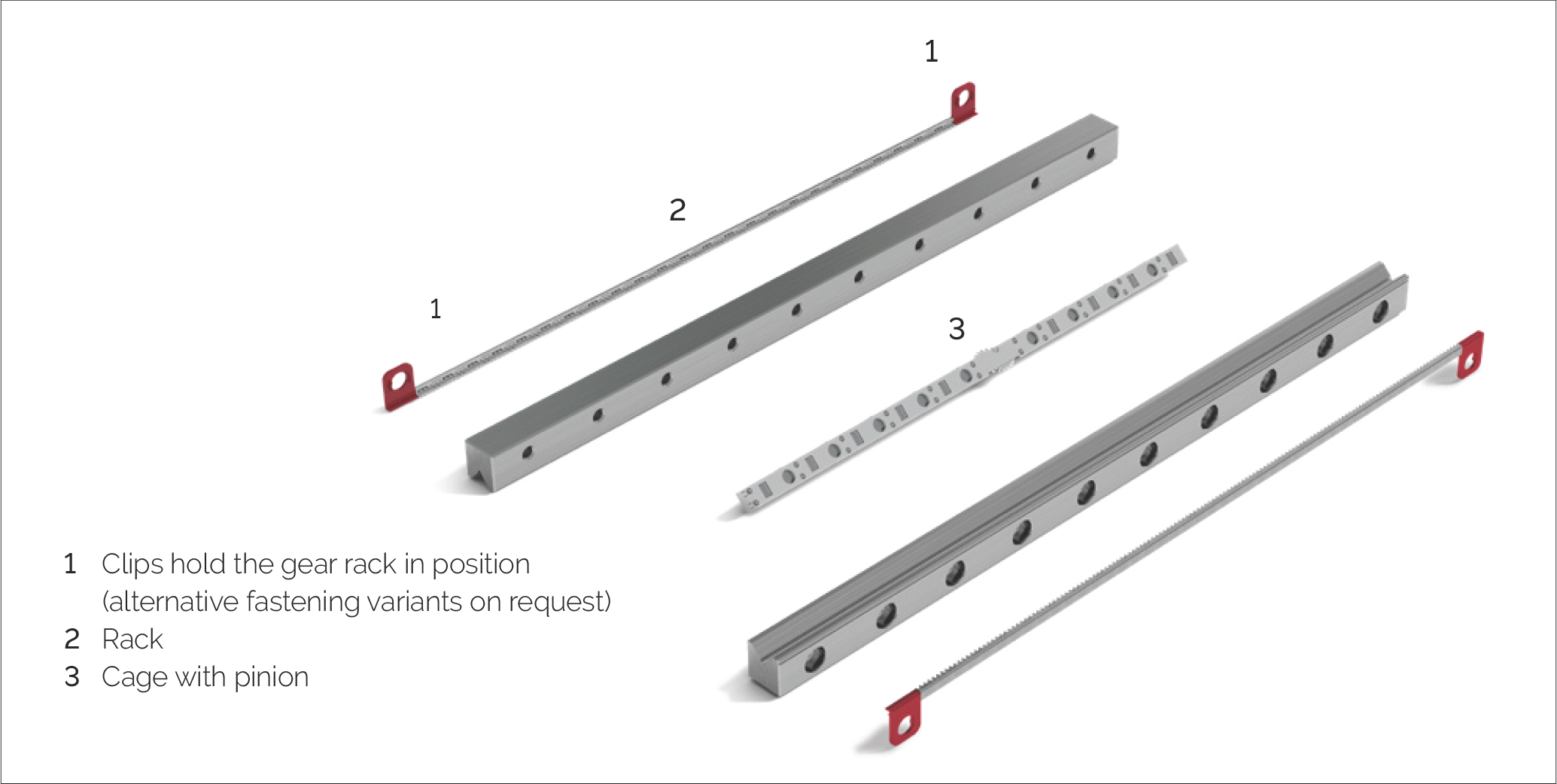

FORMULA-S fully meets requirements in terms of productivity and cost-effectiveness. It is very robust and consists of only a few components.

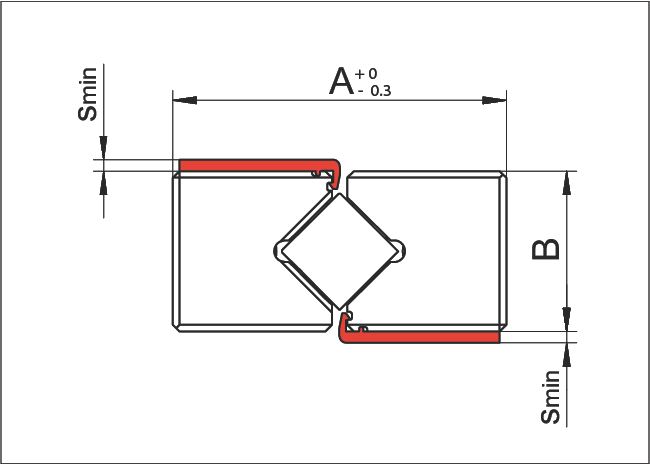

Connecting Structure

For the connecting structure, thickness Smin should be considered. The remaining dimensions correspond to guideways RN and RNG (see chapter 5, Dimensions and Load Capacities).