5.3.1 Fastening Methods

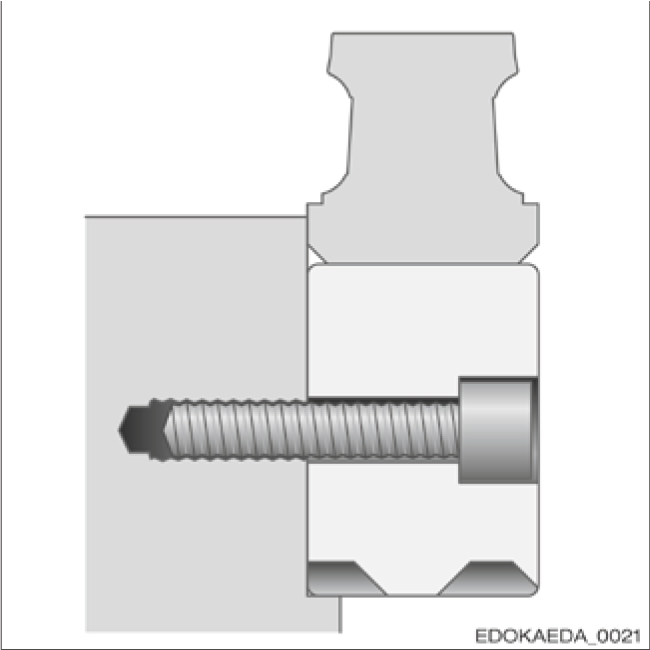

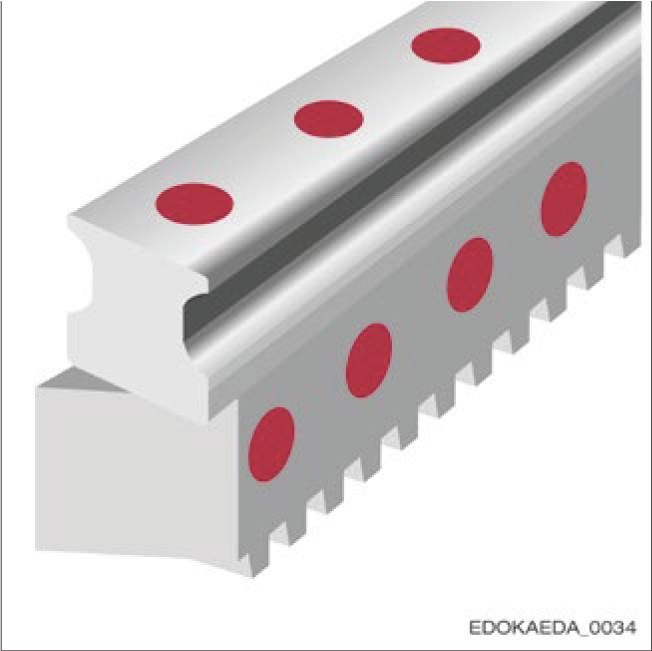

MONORAIL BZ guide rails are fastened to the connecting structure from the side. For this purpose, they have lateral through-holes with countersunk holes in the rack segment.

Fastening from the Side

Advantages:

- Fixing holes are easily accessible

- The rack is not weakened by fixing holes

5.3.2 Closures for Fixing Holes

If required, the lateral fixing holes can be closed using plastic plugs BRK. However, this is not necessary as the fixing holes are not located in the movement area of the carriage. The fixing holes for the connection screws between the guide rail and rack are also already closed with plastic plugs in the factory standard design. Instructions for installation can be found in the MONORAIL and AMS installation instructions.

Fixing Holes with Plastic Plugs

5.3.3 Permissible Screw Tightening Torques

The table below lists the maximum tightening torques for DIN 912 / ISO 4762 fixing screws. This is based on a friction coefficient μ = 0.125 upon delivery.

Fixing Screws

Component damage may result if screws are not tightened with the correct torque.

- The recommendations of the screw supplier must be followed, which are always binding.

- Low-head screws DIN 6912 should be tightened according to strength class 8.8.

Tightening Torques for DIN 912 / ISO 4762 Fixing Screws (μ = 0.125)

| Maximum Tightening Torque (Nm) | ||

|---|---|---|

| Screw | M6 | M8 |

| Guide Rail Size BZ | 25 | 35 |

| Strength Class 8.8 | 10 | 24 |

| 12.9 | 16 | 40 |

When applying grease containing MoS2 to the guide rail fixing screws and tightening with a torque wrench, a more uniform preload force can be obtained. This will significantly improve running accuracy.

Component damage may result from improperly tightened screws.

- When using grease (especially grease containing MoS2), the friction coefficient μ may be reduced by half. The tightening torque must be reduced accordingly.

- If tension loss is expected, the fixing screws can be secured. SCHNEEBERGER recommends using fixing screws with strength class 12.9.

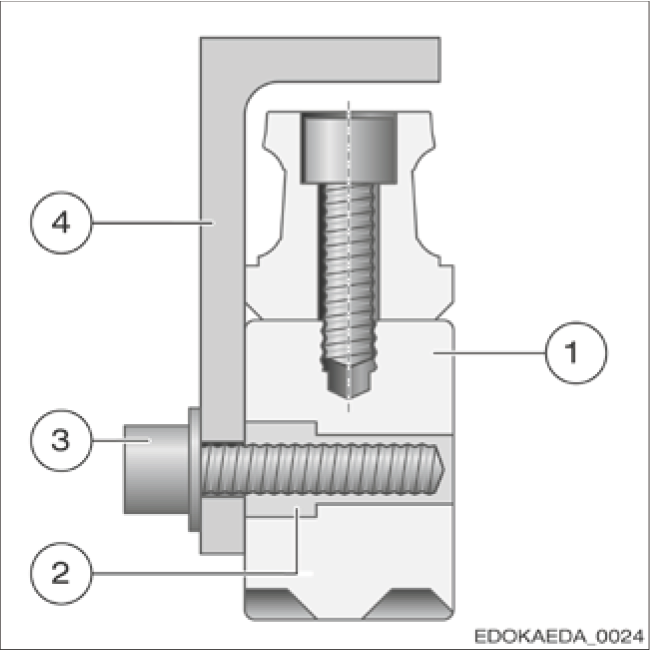

5.3.4 Transport Protection Including Installation Fixtures

MONORAIL BZ guide rails with a length > 1200 mm are equipped with transport fixtures. They consist of aluminum L-profiles connected to the BZ guide rail via several clamps. The L-profile stabilizes and protects the BZ system against bending during storage, transport, and installation. There are several tapped fixing holes on the top of the profile into which eyebolts can be screwed for lifting with lifting equipment.

The BZ system should always be transported in an upright position, i.e., with the rack facing down, as the rigidity of the guide rail and transport fixture is higher in this orientation. The transport fixture can only be removed after the BZ guide rail is fixed to the machine. For more information, see the MONORAIL BZ installation instructions.

Transport Fixture with Rack Guide Rail

- BZ System

- Clamp

- Screw

- Transport Fixture