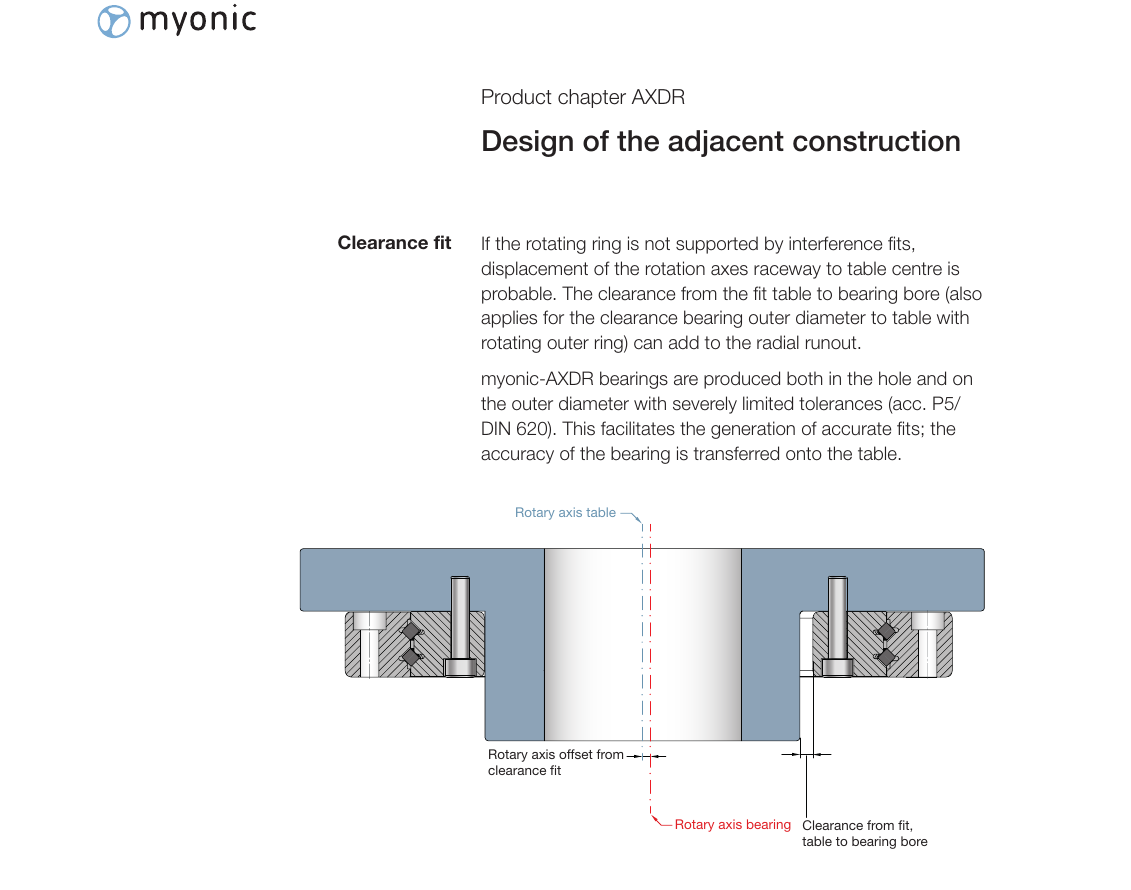

Clearance Fit

If the rotating ring is not supported by an interference fit, radial displacement of the rotating shaft to the stator center is possible. The clearance from the fit to the bearing bore (or from the fit to the bearing outside diameter) applies to the radial runout of the rotating outer ring (or rotating inner ring).

myonic AXDR bearings are less sensitive to non-positively locked shafts than AXRY bearings due to solid rings. However, reduced shaft rigidity and possible radial runout problems or rotating shaft displacement during overload must be accepted.

Radial Runout Measurement Note

Radial runout measurements using a centering table and mounted measuring ball do not match catalog values. In such precisely centered measurements, only the radial runout of the raceway and form errors of the measuring structure are measured. myonic radial runout values include radial runout error of the raceway and roundness of the bore.

Centered Shafts / Tables

Can be executed with shaft clearance fit centering with the rotating shaft. Due to solid rings, AXDR bearings are less sensitive to non-positively locked shafts than AXRY bearings. However, reduced shaft rigidity and possible radial runout problems or rotating shaft displacement during overload must be accepted.

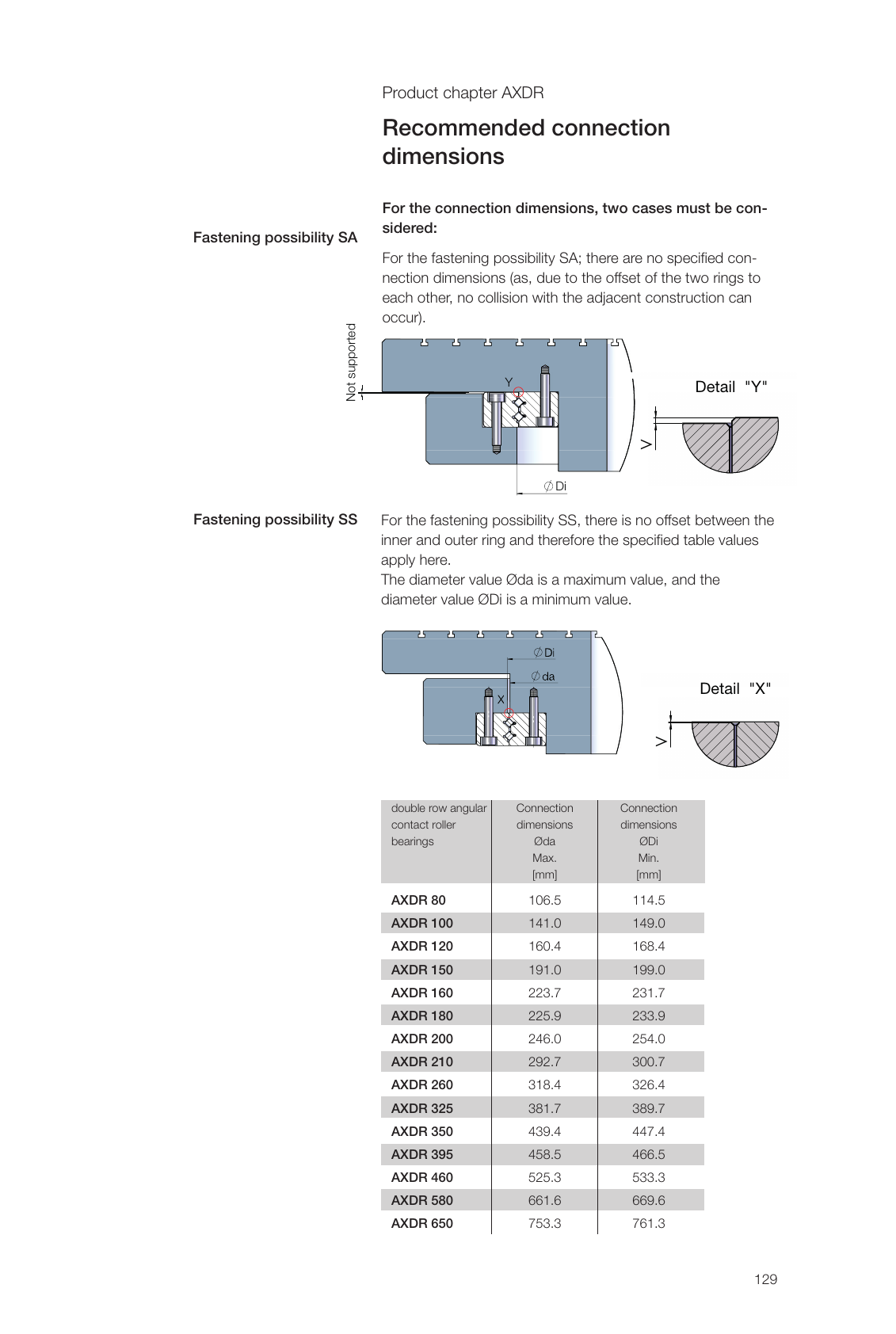

Recommended Connection Dimensions

For connection dimensions, two situations must be considered:

Fastening Method SA

For fastening method SA, there are no specified connection dimensions because the offsets of the two rings cancel each other out. No collision with adjacent structures occurs.

Fastening Method SS

For fastening method SS, there is no offset between inner and outer rings, so the specified table values apply. Diameter value ODa is maximum, diameter value IDi is minimum.

| Double Row Angular Contact Roller Bearing | Connection Dimension Ø da [mm] | Connection Dimension Ø Di [mm] |

|---|---|---|

| AXDR 80 | 108.2 | 113.4 |

| AXDR 100 | 131.0 | 140.0 |

| AXDR 120 | 157.3 | 168.2 |

| AXDR 150 | 185.5 | 198.0 |

| AXDR 160 | 223.5 | 231.2 |

| AXDR 180 | 248.0 | 256.0 |

| AXDR 200 | 273.2 | 284.0 |

| AXDR 210 | 287.0 | 298.2 |

| AXDR 260 | 314.4 | 325.4 |

| AXDR 325 | 388.5 | 399.2 |

| AXDR 350 | 420.4 | 447.4 |

| AXDR 395 | 469.4 | 504.4 |

| AXDR 460 | 527.5 | 570.0 |

| AXDR 580 | 668.0 | 720.0 |

| AXDR 650 | 755.2 | 781.2 |

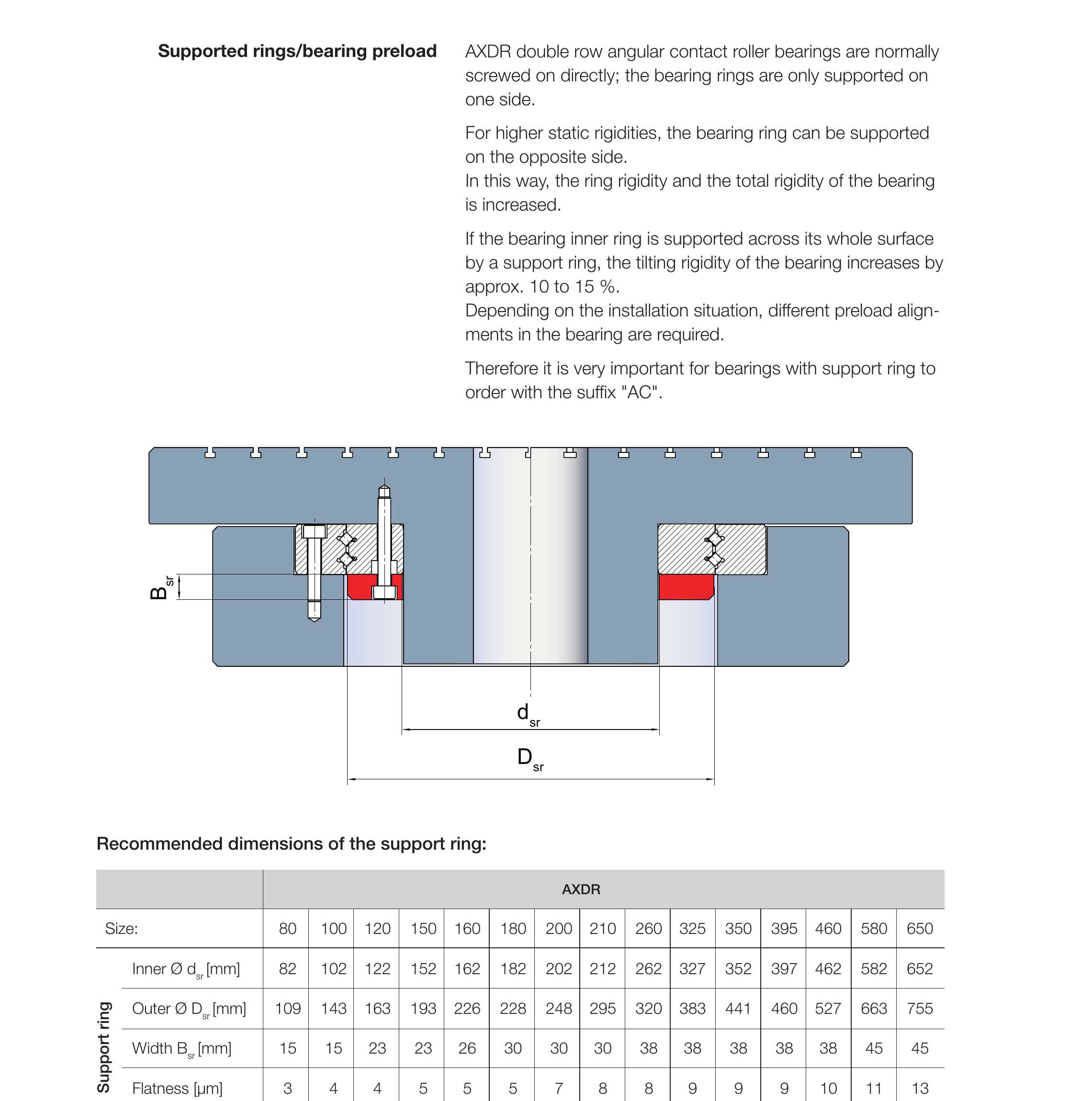

Bearing Rigidity

AXDR double row angular contact roller bearings are normally directly bolted. Bearing rings are supported on one side only.

For higher static rigidity, bearing rings can be supported on the opposite side. This way, ring rigidity and tilting rigidity of the bearing increase by approximately 10-15%.

Depending on the installation situation, different preload alignment is required in the bearing. Therefore, it is very important to order bearings with support rings together with the suffix "AC".

Recommended Support Ring Dimensions

| AXDR Size | Bore Ø Di [mm] | OD Ø Da [mm] | Height Hs [mm] | Flatness [μm] |

|---|---|---|---|---|

| 80 | 80 | 108 | 4 | 3 |

| 100 | 102 | 132 | 4 | 3 |

| 120 | 143 | 163 | 5 | 4 |

| 150 | 168 | 228 | 6 | 4 |

| 160 | 193 | 248 | 6 | 5 |

| 180 | 213 | 283 | 6 | 5 |

| 200 | 240 | 296 | 7 | 5 |

| 210 | 262 | 327 | 8 | 6 |

| 260 | 302 | 363 | 8 | 6 |

| 325 | 361 | 441 | 9 | 7 |

| 350 | 389 | 481 | 9 | 8 |

| 395 | 433 | 527 | 10 | 8 |

| 460 | 497 | 582 | 10 | 9 |

| 580 | 627 | 703 | 11 | 11 |

| 650 | 702 | 793 | 12 | 13 |

Surface Requirements

Ra 0.8 μm - Support ring surface roughness requirement

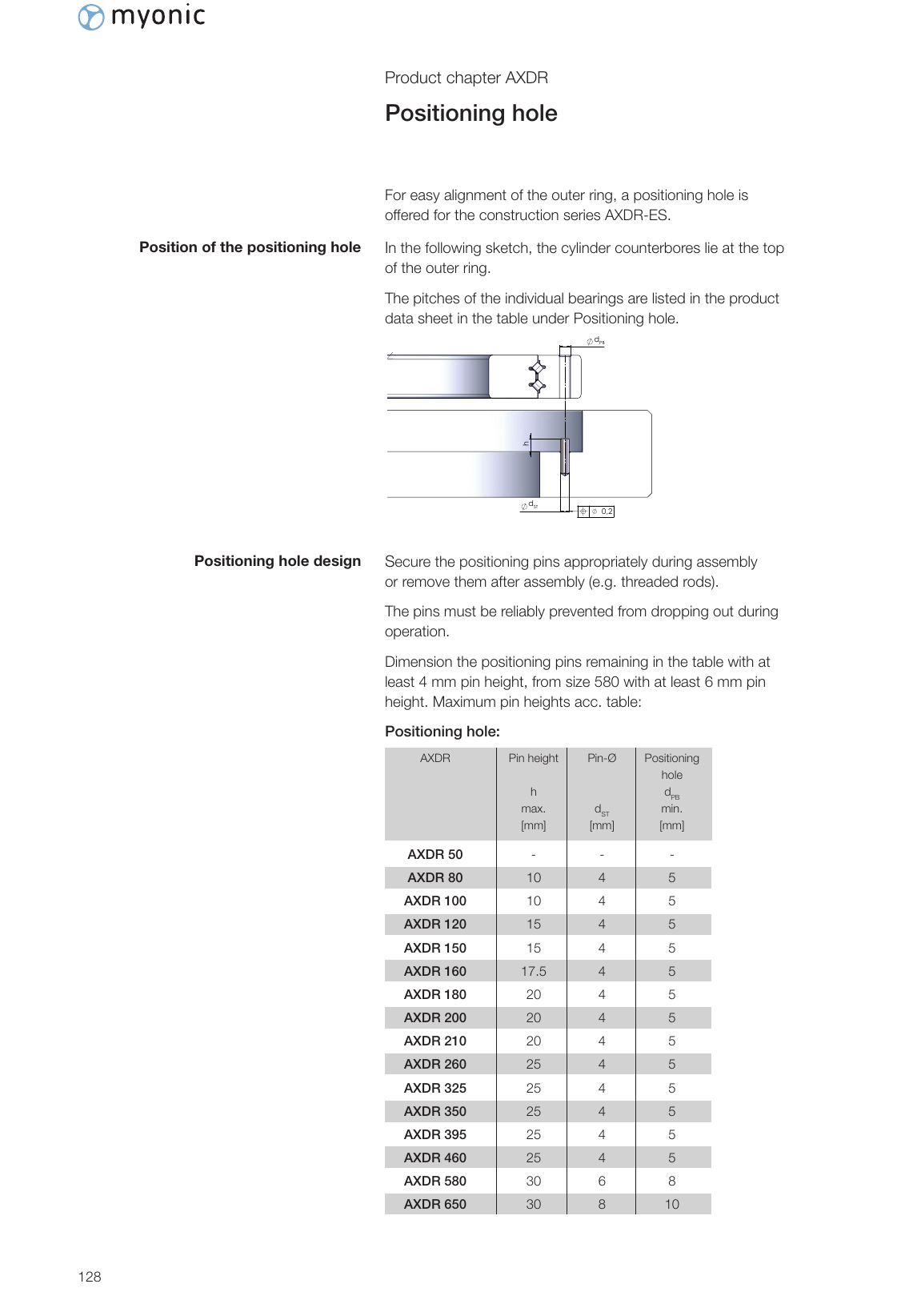

Positioning Hole

To facilitate outer ring alignment, structural series AXDR-ES provides positioning holes.

In the following sketch, the cylindrical counterbore is located on the top of the outer ring. The spacing for each bearing is listed under "Positioning Hole" in the product data sheet.

Positioning Hole Design

Properly secure the positioning pin during assembly or remove it after assembly (e.g., threaded rod).

The pin must be reliably prevented from falling out during operation.

Positioning pin dimensions should be designed according to the remaining minimum 4 mm pin height in the table, from size 580 at least 6 mm pin height.

Positioning Hole Dimensions

| AXDR | Pin Height h max. [mm] | Pin Ø dst [mm] | Positioning Hole Ø dbo min. [mm] |

|---|---|---|---|

| AXDR 50 | - | - | - |

| AXDR 80 | 10 | 4 | 5 |

| AXDR 100 | 10 | 4 | 5 |

| AXDR 120 | 15 | 4 | 5 |

| AXDR 150 | 15 | 4 | 5 |

| AXDR 160 | 17.5 | 4 | 5 |

| AXDR 180 | 20 | 4 | 5 |

| AXDR 200 | 20 | 4 | 5 |

| AXDR 210 | 20 | 4 | 5 |

| AXDR 260 | 25 | 4 | 5 |

| AXDR 325 | 25 | 4 | 5 |

| AXDR 350 | 25 | 4 | 5 |

| AXDR 395 | 25 | 4 | 5 |

| AXDR 460 | 25 | 4 | 5 |

| AXDR 580 | 30 | 6 | 8 |

| AXDR 650 | 30 | 8 | 10 |