The amount of preload depends on the intended use of the guideway. High preload:

- … increases the rigidity of the guideway and guarantees zero clearance

- … reduces moment loads and maximum loads on rolling elements

- … increases displacement resistance

- … reduces service life

The positive effects of preload are achieved when preload reaches 5% - 20% of the permissible load C.

General Approach

Preload can be set uniformly using a torque wrench. In this process, the friction between the screw and threaded fixing hole must be considered (determined through testing).

When using wedge adjusters or adjustment plates, the ideal preload must be determined based on the total elastic deformation δA (see Chapter 12.5) and the deformation of the connecting structure.

When setting R guideways with EE type slides, the slide must be slightly compressed before the rollers are applied.

As mentioned above, preload increases the rigidity of the guideway. However, high preload requires a stable connecting structure. Otherwise, due to angular errors, undesirable edge loading of rollers and needles will occur, which in turn negatively affects load capacity.

Procedure for Linear Guideways

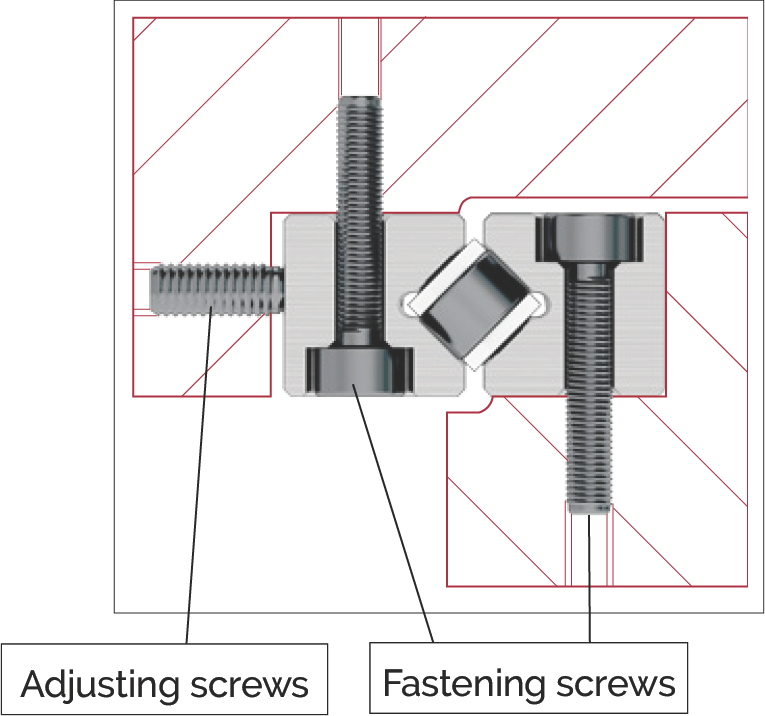

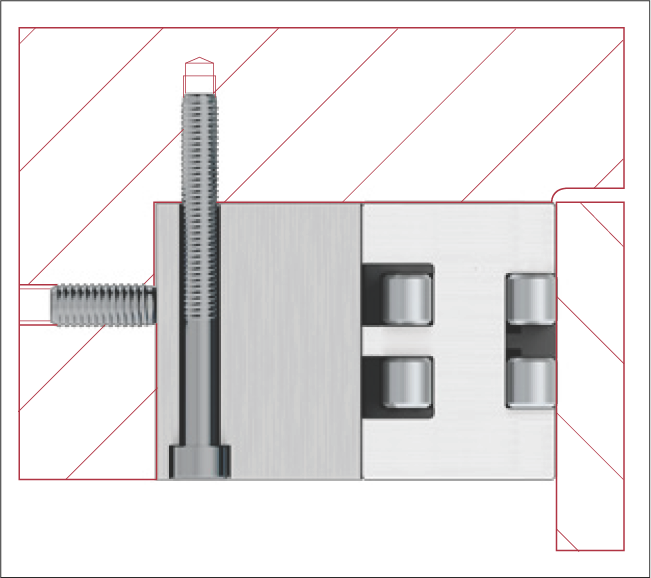

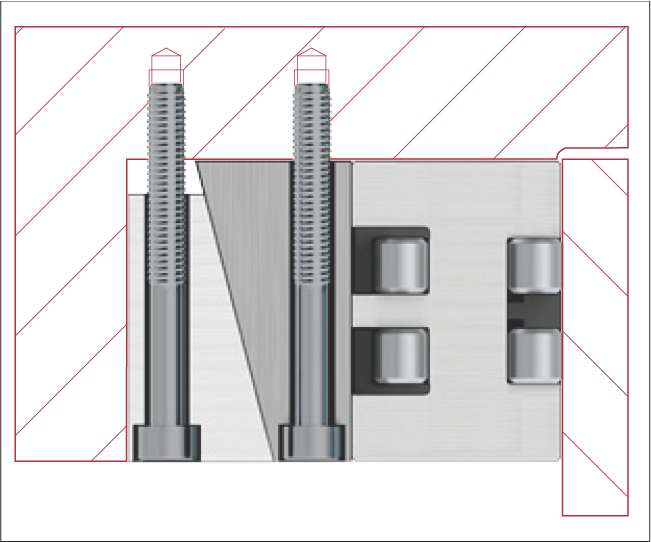

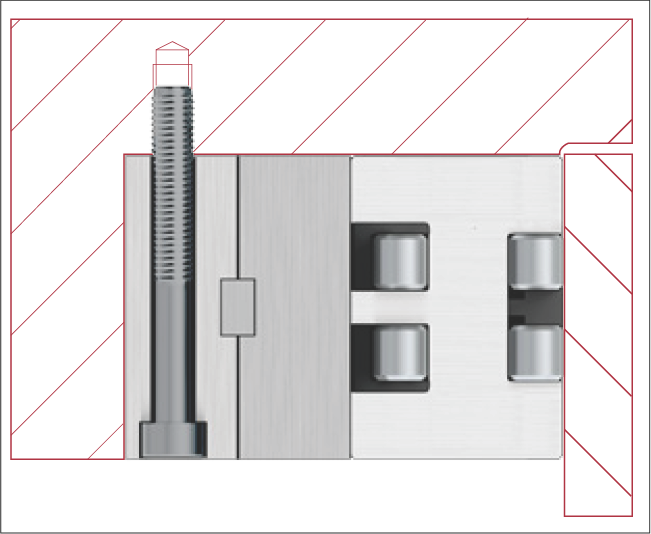

Typically, guideways are set to zero clearance using adjusting screws. Zero clearance and uniform sequence can only be achieved when advancement occurs only at the location where the slide with rolling elements is positioned (also see Chapter 13.9).

At least one adjusting screw must be provided for each fixing screw, with thread size matching that of the fixing screw. For overtravel slides, advancement of the shorter guideway should be preferred.

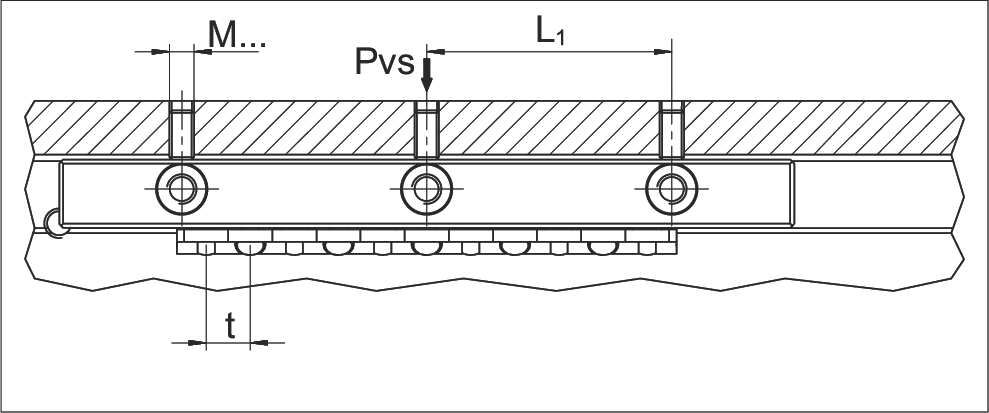

Calculation Example for Advancement Force (Pvs) and Tightening Torque (Mds) per Adjusting Screw

Information required for each calculation:

- Linear guideway type R 3, L₁ = 25 mm

- Roller slide type AC 3, t = 5 mm

- C = 130 N

- Adjusting screw diameter = M4

- Factor f (Rollers = 1; Balls/Needles = 2) f = 1

- Preload p (2% to 20% of C) p = 10%

- Factor a (unit: cm, see table below)

Thread and Factor a

| Thread | Factor a |

|---|---|

| M2 | 0.0238 |

| M2.5 | 0.0294 |

| M3 | 0.035 |

| M4 | 0.0469 |

| M5 | 0.058 |

| M6 | 0.0699 |

| M8 | 0.0926 |

| M10 | 0.1152 |

| M12 | 0.1378 |

| M14 | 0.1591 |

| M16 | 0.1811 |

Calculating Advancement Force Pvs per Adjusting Screw

Pvs = L₁ / t · C · p / 100 · f

Pvs = 25 / 5 · 130 · 10 / 100 · 1 = 65 N

Calculating Tightening Torque Mds

Mds = Pvs · a

Mds = 65 · 0.0469 = 3.05 Ncm

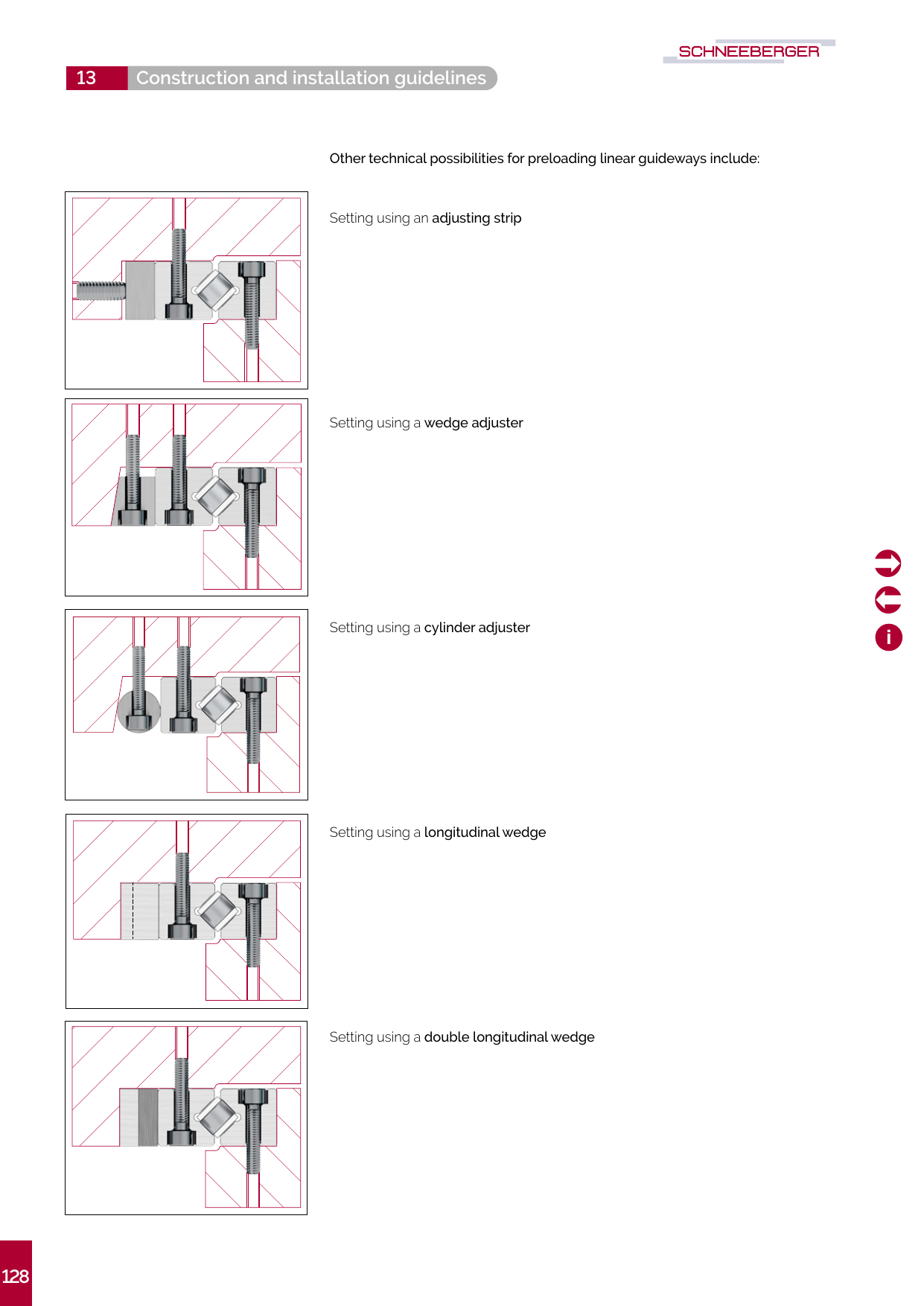

Other Technical Possibilities for Preloading Linear Guideways Include:

- Setting using adjusting strips - Set preload using adjusting strips

- Setting using wedge adjusters - Set preload using wedge adjusters

- Setting using cylindrical adjusters - Set preload using cylindrical adjusters

- Setting using longitudinal wedges - Set preload using longitudinal wedges

- Setting using double longitudinal wedges - Set preload using double longitudinal wedges

Preload Procedure for Recirculating Units (SK, SKD, SKC and SR)

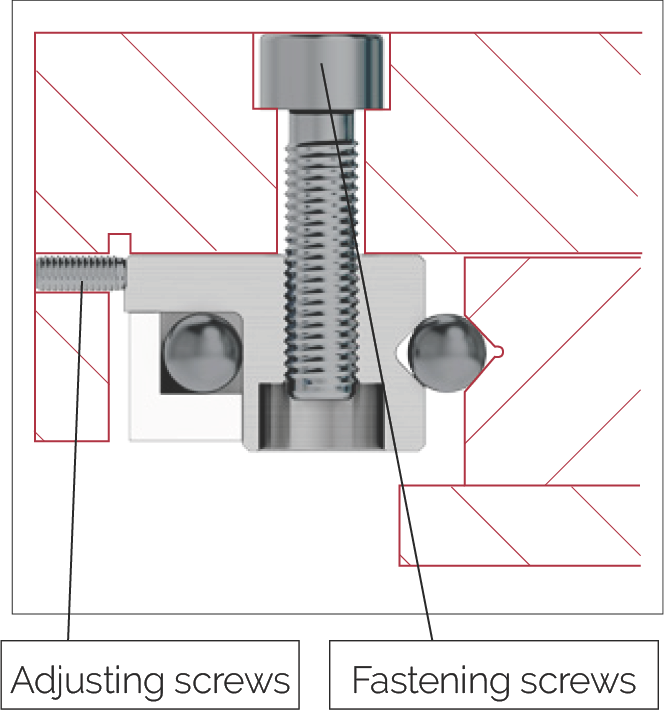

Recirculating units are typically set to zero clearance using adjusting screws. At least one adjusting screw must be provided for each fixing screw, with thread size matching that of the fixing screw.

Calculation Example for Advancement Force (Pvs) and Tightening Torque (Mds) per Adjusting Screw

Information required for each calculation:

- Recirculating unit SK 6-100

- Adjusting screw diameter = M4

- Number of adjusting screws N = 2

- Factor f (Rollers = 1; Balls = 2) f = 2

- Preload p (5% to 20% of C) p = 10%

- C = 715 N

- Factor a (unit: cm, see table below)

Thread and Factor a

| Thread | Factor a |

|---|---|

| M2 | 0.0238 |

| M2.5 | 0.0294 |

| M3 | 0.035 |

| M4 | 0.0469 |

| M5 | 0.058 |

| M6 | 0.0699 |

| M8 | 0.0926 |

| M10 | 0.1152 |

| M12 | 0.1378 |

| M14 | 0.1591 |

| M16 | 0.1811 |

Calculating Advancement Force Pvs per Adjusting Screw

Pvs = C / N · p / 100 · f

Pvs = 715 / 2 · 10 / 100 · 2 = 71.5 N

Calculating Tightening Torque Mds

Mds = Pvs · a

Mds = 71.5 · 0.0469 = 3.35 Ncm

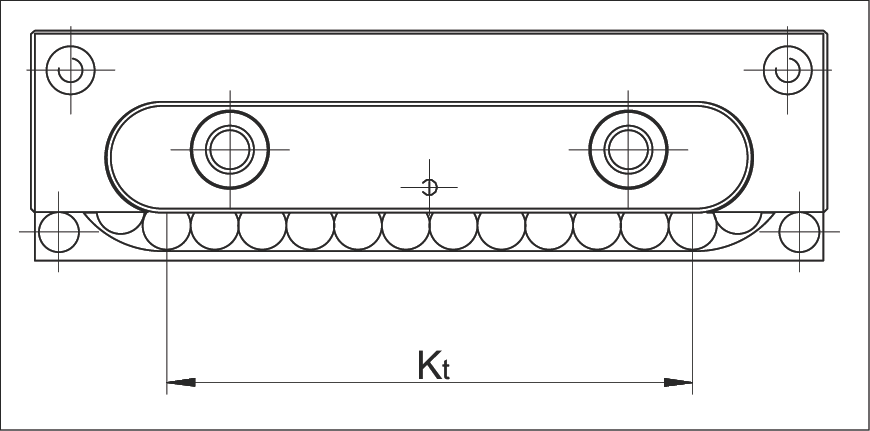

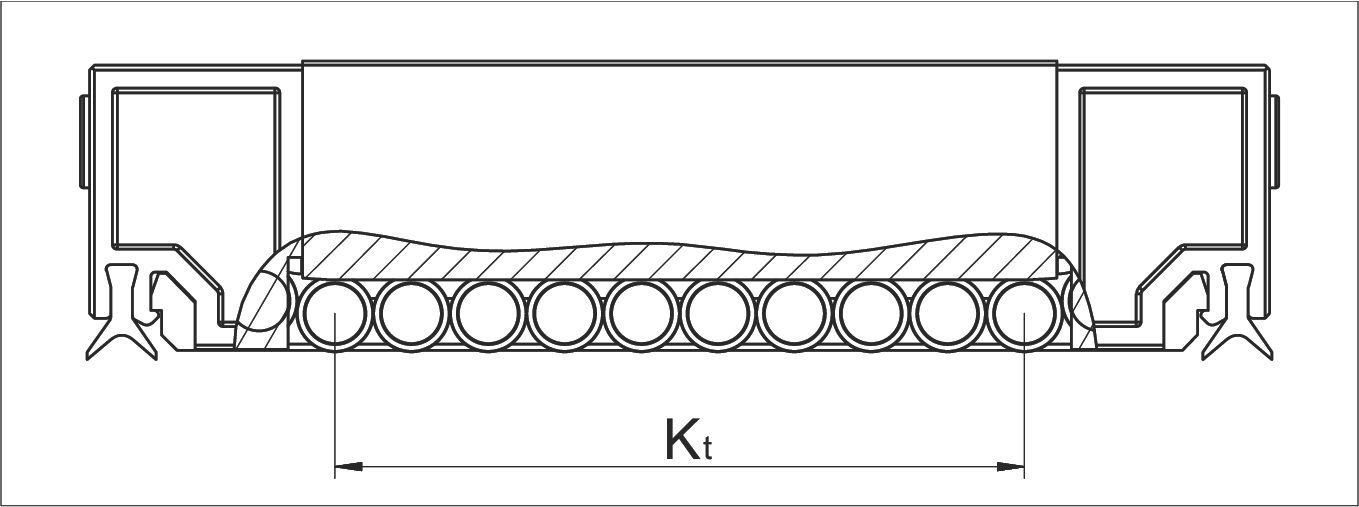

Note: Advancement must always remain within the load length Kt!

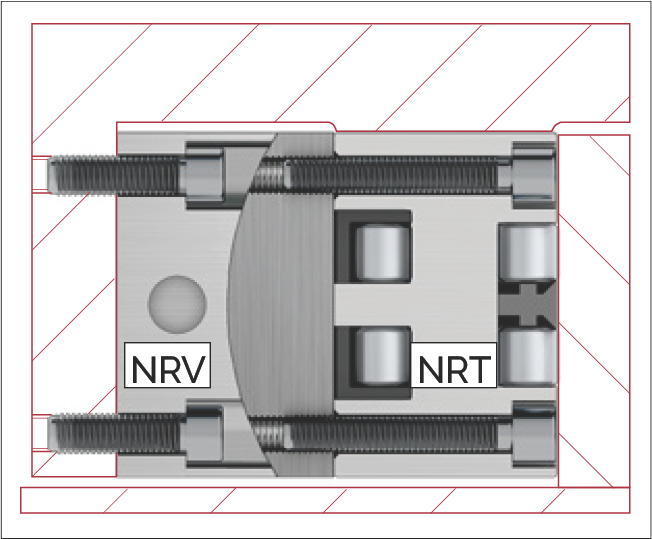

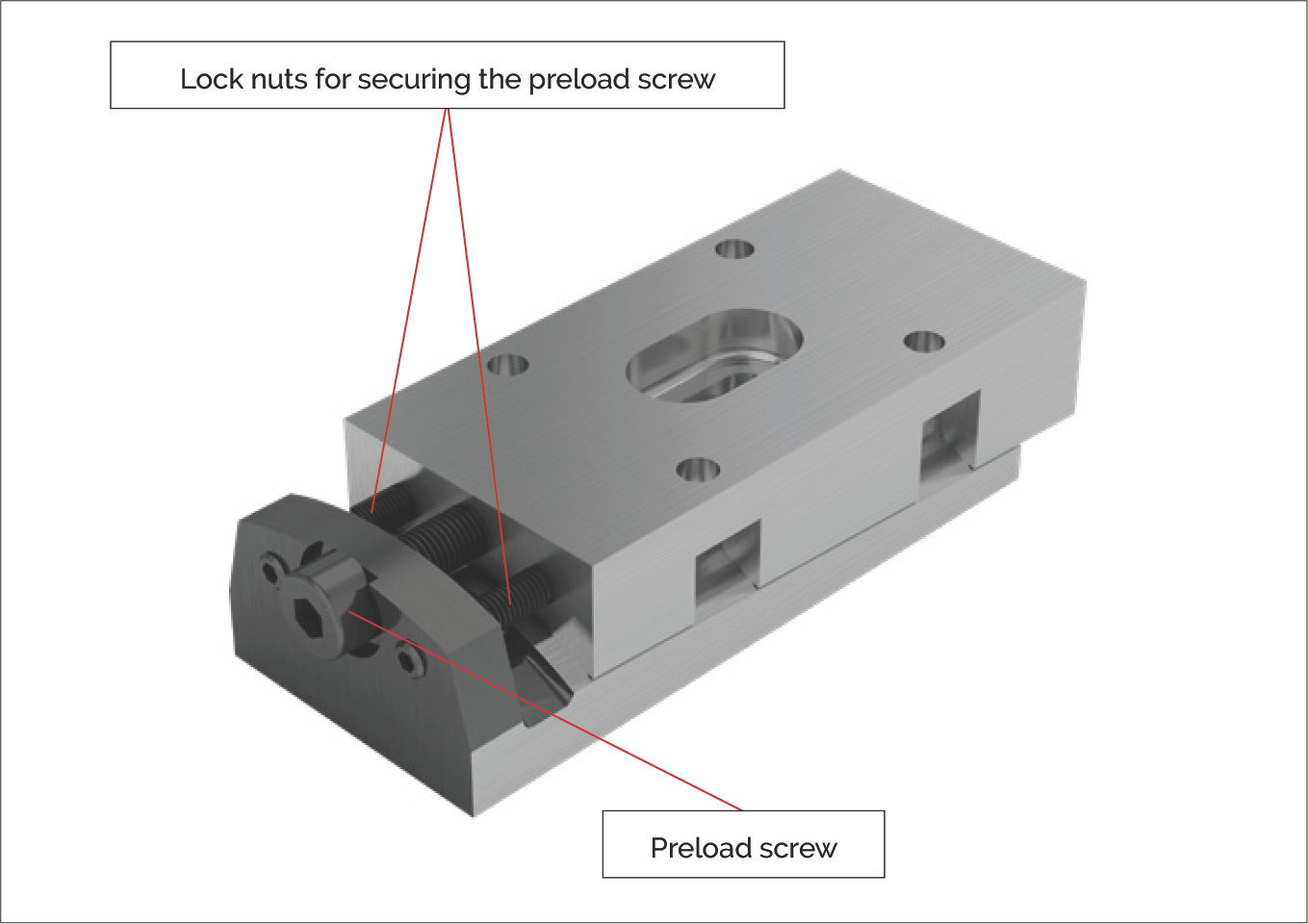

Preload Procedure for Recirculating Unit NRT Using Preload Wedge NRV

When preloading using preload wedge NRV, the following advancement values apply:

Advancement Values for Preload Wedge NRV

| Type | Size | Max. Adjustment Range (height, mm) | Height Difference A per Revolution of Preload Screw |

|---|---|---|---|

| NRV | 19077 | 0.35 | 0.0350 |

| 26111 | 0.40 | 0.0625 | |

| 26132 | 0.40 | 0.0625 | |

| 38144 | 0.40 | 0.0750 |

Note: After successfully setting the preload, the two lock nuts should be tightened alternately, applying the same torque using a wrench!

Important: If preloading without using preload wedge NRV, ensure that advancement always remains within the load length Kt.

Other Technical Possibilities for Preloading NRT Include:

Setting using intermediate plate

Setting using wedge adjuster

Setting using adjusting screw