13.2 MINISLIDE MSQ Product Characteristics

13.2.1 Extensive Product Range

The MSQ series includes guide rail widths of 7, 9, 12 and 15 mm, with four or five different lengths and strokes available depending on type.

MSQ 15

| System length (mm): | 70 – 130 |

|---|---|

| Stroke (mm): | 66 – 102 |

MSQ 12

| System length (mm): | 50 – 100 |

|---|---|

| Stroke (mm): | 45 – 70 |

MSQ 9

| System length (mm): | 40 – 80 |

|---|---|

| Stroke (mm): | 34 – 66 |

MSQ 7

| System length (mm): | 30 – 70 |

|---|---|

| Stroke (mm): | 20 – 58 |

System lengths of the MINISLIDE MSQ series

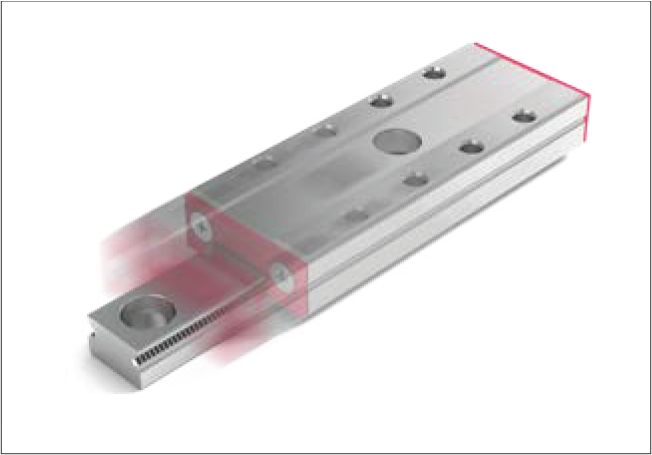

13.2.2 High Speeds and Accelerations

High acceleration applications require well-thought-out solutions. With its unique integrated cage control design, MINISLIDE MSQ meets the requirements of the most modern drive technologies, allowing speeds up to 3 m/s and accelerations up to 300 m/s².

MINISLIDE MSQ allows speeds up to 3 m/s and accelerations up to 300 m/s²

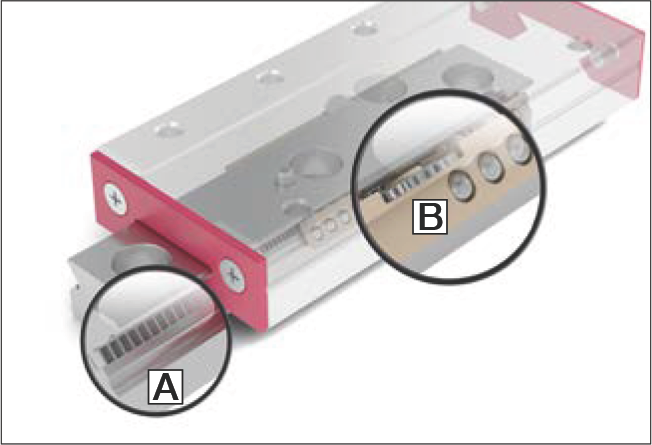

13.2.3 High Process Reliability Through Cage Control

The cage can move freely along the longitudinal axis on every linear guideway. Due to uneven weight distribution, high acceleration, vertical installation or temperature differences, the cage often deviates from the center position. This so-called cage creep impairs the efficiency of every application because corrective strokes must be performed periodically to center the cage, consuming energy.

MINISLIDE MSQ products are equipped with a carefully designed robust cage control system that eliminates cage creep. The rack and pinion of the control system is directly integrated into the carriage and guide rail. The cage and pinion are made of high-quality plastic.

The compact, robust design with minimal integrated components ensures maximum strength in every commercial situation.

Mechanical stroke limits protect the cage control mechanism and make installation and maintenance easy (they must not be used as a means of limiting the stroke during operation).

Robust cage control of MINISLIDE MSQ

A Rack and pinion on carriage and guide rail

B Cage with pinion

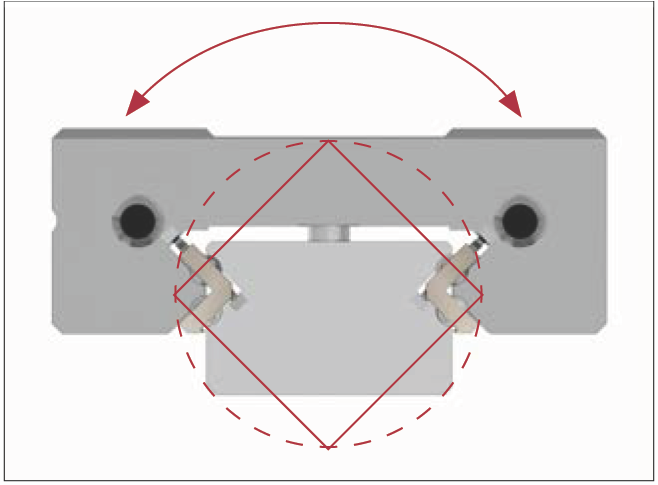

13.2.4 Maximum Stiffness and Load Capacity

MINISLIDE MSQ products feature four circular arc profile tracks. They are arranged in an O-configuration, ensuring a large internal spacing. Combined with tracks offset by 90 degrees, a high level of uniform force distribution from all directions and torsional stiffness is achieved.

The four circular arc profile tracks of MINISLIDE MSQ are arranged in an O-configuration

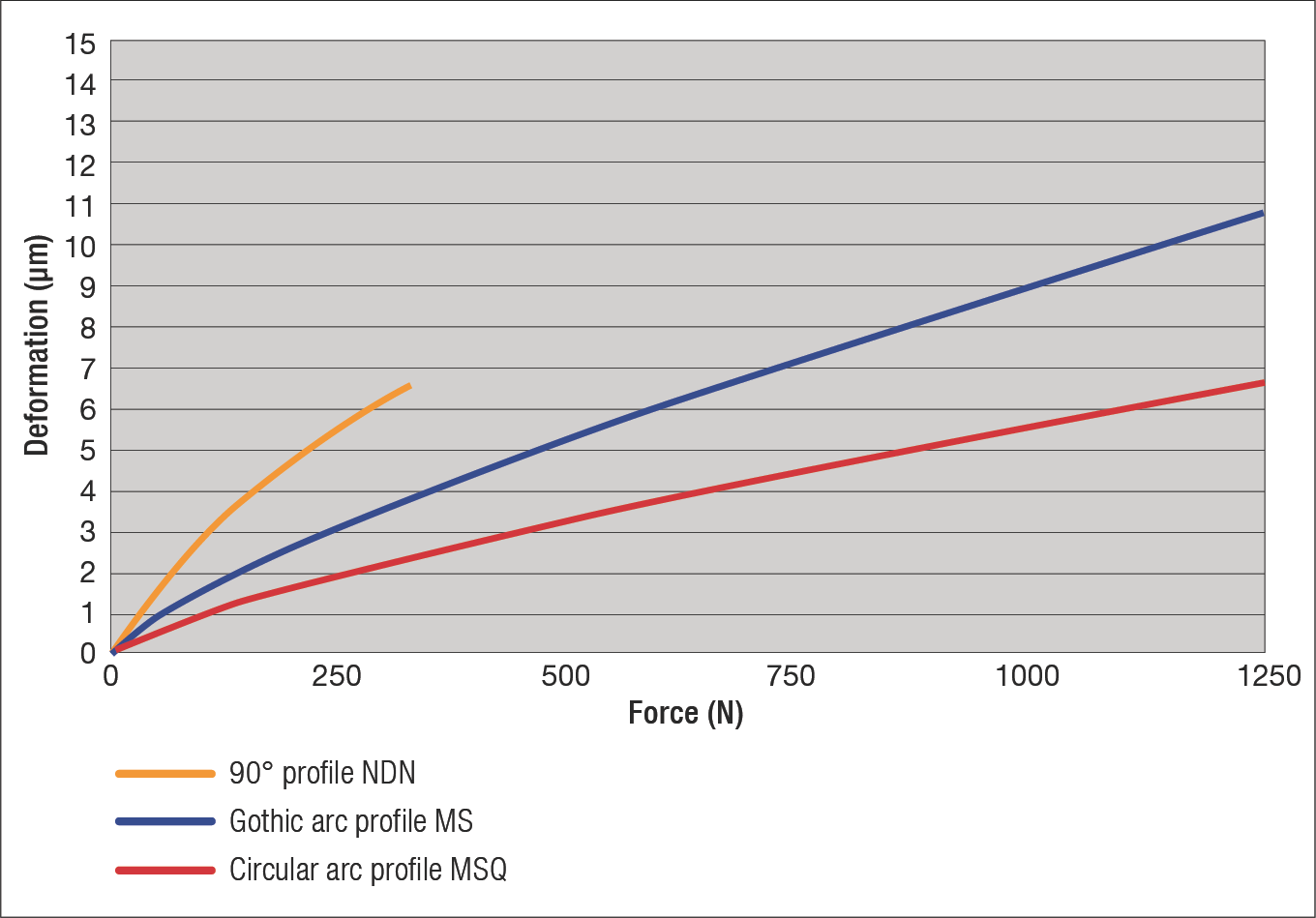

MINISLIDE products have preload with zero backlash. Combined with the large number of rolling elements, a high level of system stiffness is guaranteed, thus ensuring the highest precision.

Stiffness comparison of structurally identical MINISLIDE size 9-80.66 with different guideway track profiles. The circular arc profile of MSQ results in the lowest deformation, thus the highest stiffness