AM Ball Screws - Installation & Protection

Installation Notes & Protective Devices

Installation Notes

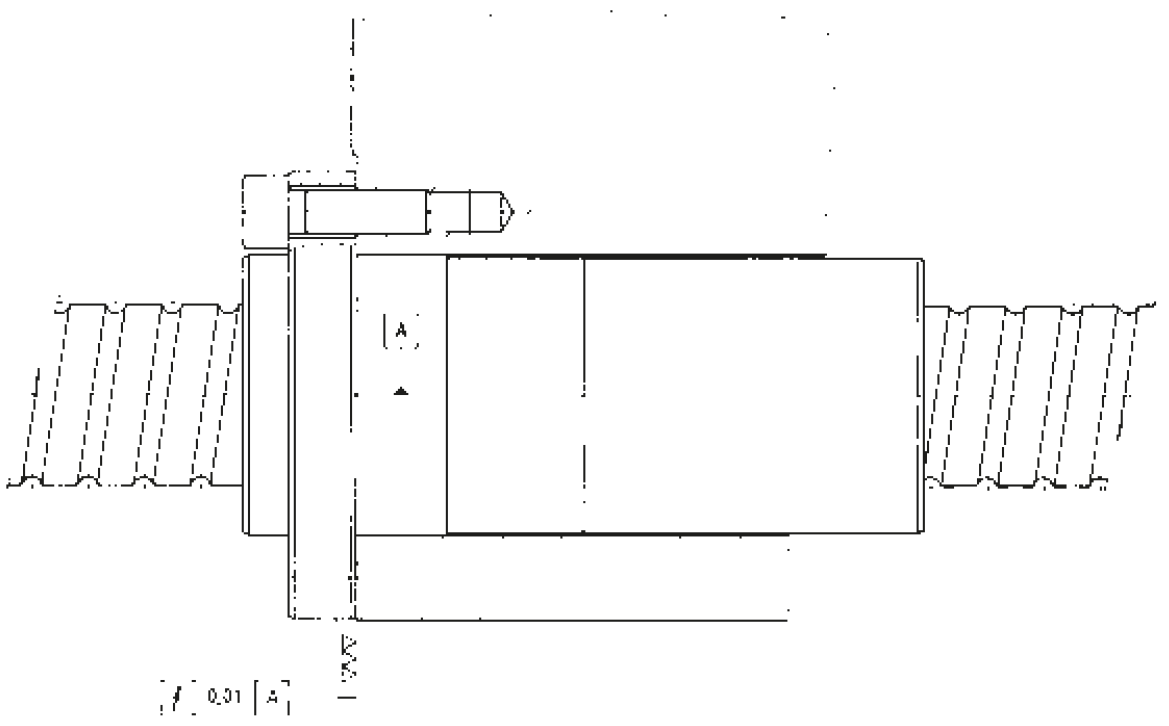

To ensure proper function, we recommend that the perpendicularity of your flange locating surface to the screw axis be maintained within the range shown in the illustration, i.e., alignment of bearings and guide rails must also be observed.

Important Warnings

- The nut must be prevented from being subjected to any static or dynamic radial forces

- Disassembly of the nut is prohibited

In the case of vertical ball screw applications, the machine manufacturer must check whether a safety stop device needs to be provided.

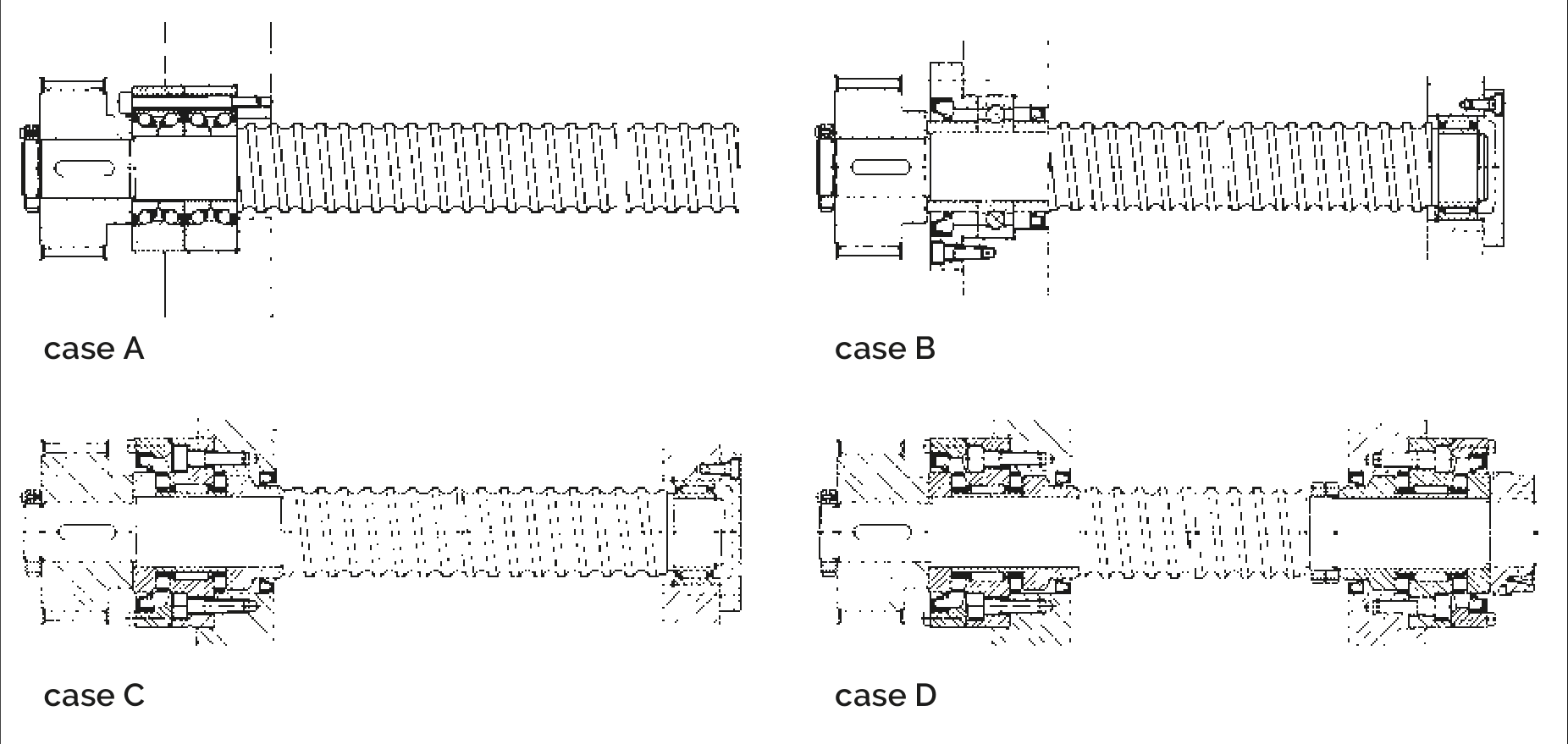

Bearing of Spindles

Bearing of Spindles - Case A, B, C, D

Protective Devices

Contaminants and Foreign Objects

The working space of the ball screw should be protected by appropriate covers to prevent chips, abrasive particles, or other foreign objects from entering.

Even soft particle deposits such as fibers, wood shavings, and other substances that obstruct the lubricating film must be avoided.

In principle, we recommend the use of wipers.

Overload Protection

Overload from Collision or Impact

Overload clutches and predetermined breaking points are recommended because impact loads exceeding the static load rating may occur during collisions. This protection is especially important when the screw has a high moment of inertia.

If limit switches are overrun, buffer devices can prevent damage.

Storage Notes

Storage Requirements

Never place ball screws on the nut; store them on V-blocks.

Installation Checklist

| Item | Check Content |

|---|---|

| Alignment | Confirm perpendicularity of flange locating surface to screw axis |

| Bearing Configuration | Select appropriate bearing configuration (B or D) according to application |

| Protective Devices | Install appropriate covers and wipers |

| Overload Protection | Consider installing overload clutches or buffer devices |

| Vertical Applications | Evaluate whether a safety stop device is required |

| Lubrication | Confirm lubrication system is properly configured |