5.6.1 Protection at Delivery

MONORAIL BZ systems are shipped with oil as standard protection. This provides protection during storage, transport, and installation. Before starting up the guide rail, the rack must be initially lubricated.

For more detailed information on protection for SCHNEEBERGER MONORAIL guide rails, see Section 4.15 - Lubrication.

Lubricant Used for Protection:

A synthetic oil-based anti-corrosion protection oil with viscosity grade ISO VG 15 is used, which does not harden. This ensures that the gear drive does not have to be cleaned before installation.

Note: SCHNEEBERGER rust inhibitor is compatible with other mineral oil-based lubricants. However, compatibility with the lubricant used must be checked.

5.6.2 Initial and Subsequent Lubrication

Before starting up the MONORAIL BZ system, the guide rail and rack drive should be basically lubricated with oil or grease. For this purpose, the rack and drive pinion can be sufficiently wetted manually (e.g., using a brush), or lubricant can be applied automatically using an attached felt pinion. The felt pinion meshes with the teeth of the rack and transfers lubricant. In this way, a uniform lubricant film is applied. The lubricant supply is provided by the bearing. A lubrication nipple or independent lubricant distributor can be attached here. This will provide you with automated lubrication. Lubricant supply through the machine's central lubrication system is generally not considered, as the lubricant viscosity used for the rack drive is usually much higher than that used for SCHNEEBERGER MONORAIL guide rails. Before starting automatic lubrication, the felt pinion (BZR) should be completely saturated with lubricant.

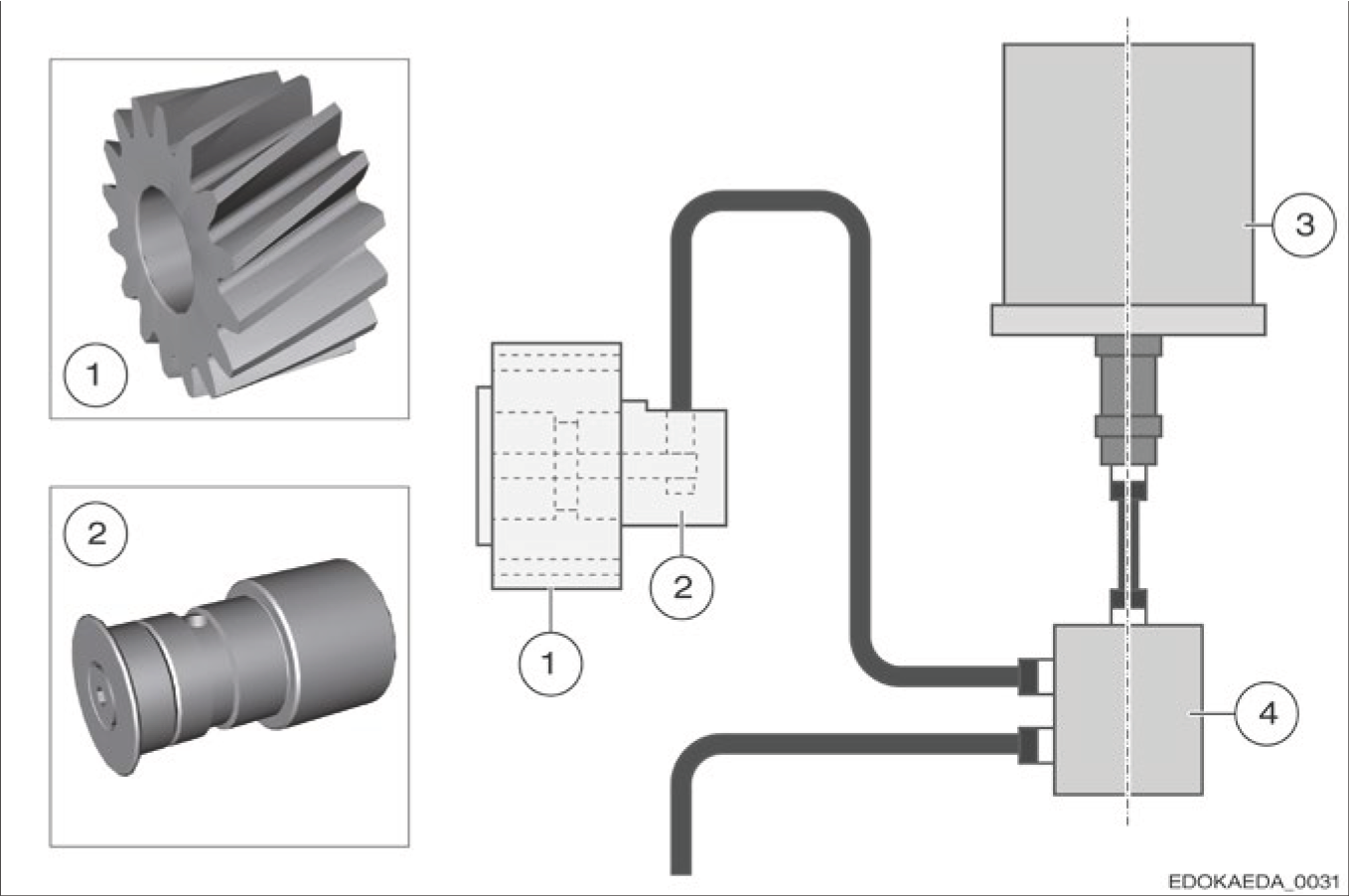

Independent Lubricant Distributor System

Independent Lubricant Distributor:

- 1Lubrication pinion

- 2Pinion hub for lubrication pinion

- 3Lubrication pump

- 4Lubricant distributor

Subsequent Lubrication

To maintain the operability of the rack drive, in addition to the initial basic lubrication, regular subsequent lubrication is usually required. Use the same lubricant as for initial lubrication, and check the compatibility of subsequent lubrication with the basic lubricant.

Important: Lubrication intervals vary greatly depending on the application and must be determined during operation.

Felt Pinion Maintenance: The felt pinion wears and hardens over time. Therefore, regular inspection is required, and replacement if applicable. Its average service life is approximately one year.

For information on lubricating guide rails, see Section 4.15 - Lubrication. For lubrication accessories for MONORAIL BZ, see the SCHNEEBERGER MONORAIL and AMS product catalog.

5.6.3 Coating

Optional Configuration: MONORAIL BZ systems with surface coating for corrosion protection can be provided upon request.

Important Note: It should be noted that only the carriage and guide rail will be coated. The rack and pinion provided as accessories should remain uncoated.

Advantages of Coating

Surface coating can significantly improve the system's corrosion resistance in harsh environments, extend service life, and reduce maintenance requirements. The coating is applied only to guide rail and carriage elements to ensure optimal corrosion protection while maintaining the mechanical performance of the rack drive system.

Application Considerations

When selecting coating options, consider your specific application environment, including humidity, temperature variations, and potential chemical exposure. SCHNEEBERGER can provide recommendations on the most suitable coating type for your application.