AM Ball Screws - Lubrication

Lubrication - Oil and Grease Lubrication

Basic Lubrication Requirements

Oil or grease lubrication conforming to roller bearing lubrication specifications is absolutely necessary for ball screws. Life calculations assume an elastohydrodynamic lubricating film.

In principle, commercially available mineral oils and greases for roller bearings and gearboxes are suitable. For high-speed applications, synthetic oils have proven effective.

Prohibited

Solid lubricant additives such as graphite, molybdenum disulfide (as dry lubrication or dispersed in oil) are prohibited.

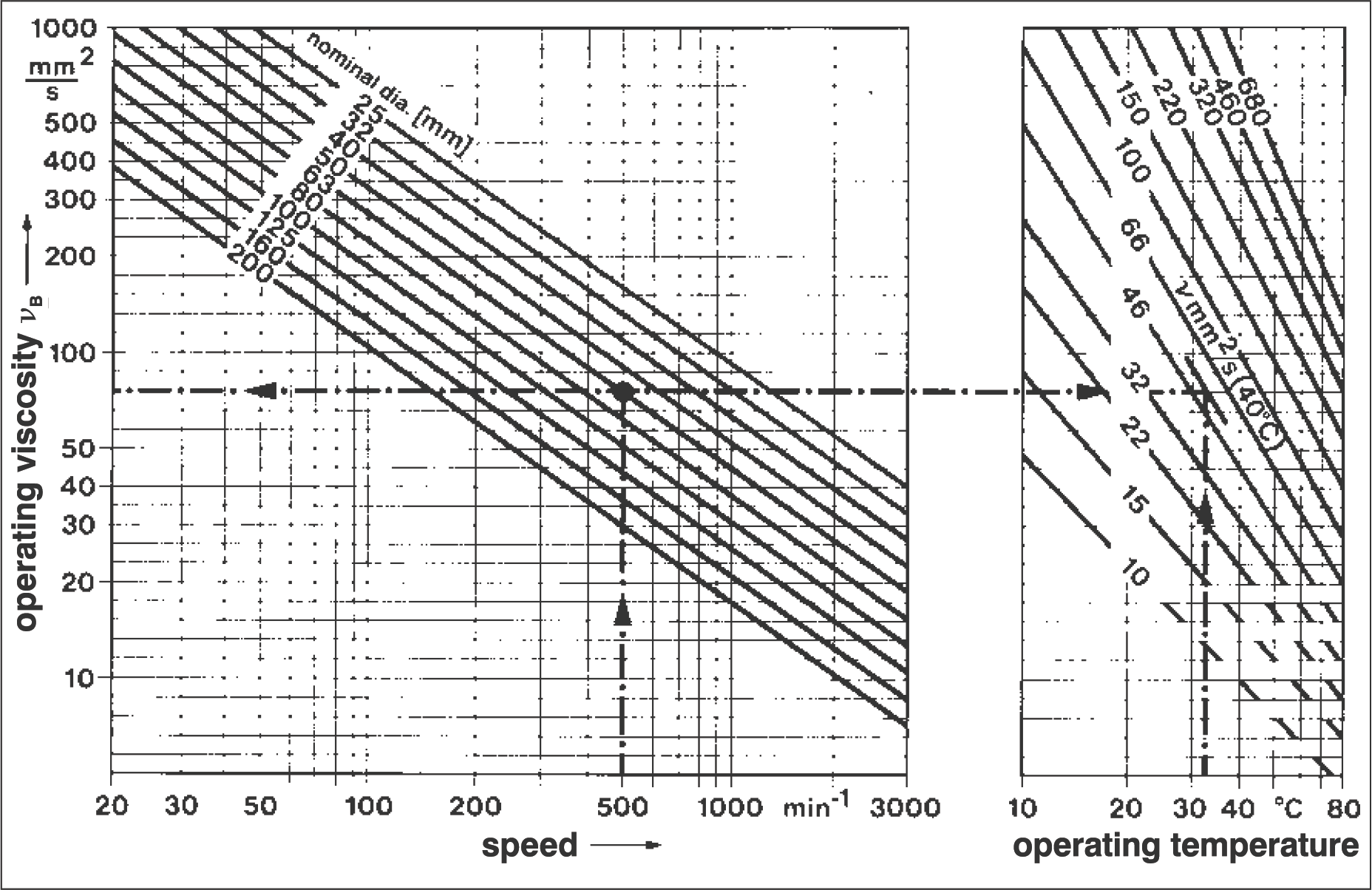

The chart contains characteristics and selection criteria important for normal operating conditions. When the customer does not have any special lubrication instructions, performance tests and delivery will be carried out using lubricating oil DIN 51517/3 CLP ISO VG 100.

Oil Lubrication

The most suitable oil viscosity can be determined from the chart based on speed, nominal diameter, and operating temperature. The minimum viscosity at operating temperature is 21 cSt.

Viscosity Selection Considerations

In addition to the viscosity determined according to the speed range, the load has a decisive influence on the chemical additives for increasing load capacity:

- For loads Fa > 0.15 Cam, CLP lubricating oils with EP additives conforming to German standard DIN 51517 Part 3 must be used (maximum limit stress in failure load stage at least 12)

Lubricating Oil Quantity

The lubricating oil quantity depends on operating and screw data.

Example

Ball screw d0 = 50, P = 20, nmax = 3,000 min-1 should operate with a minimum lubricating oil quantity of 0.5 cm3/h.

Increasing the lubricating oil quantity can improve the flushing effect of any contaminants.

Grease Lubrication

Grease Lubrication

| NL GI-class DIN 51878 | Fulling penetration acc. DIN 51804 | Lithium soap grease | Synthetical special grease | |

|---|---|---|---|---|

| (Fa ≤0.15 Cam) without EP-additives | (Fa>0.15 Cam) with EP-additives | |||

| 0 | 355-385 (semi-liquid fluid grease) | – | high load up to 800 min-1 | high speed-application up to 4,000 min-1 |

| 1 | 310-340 (very soft) | interior load up to 800 min-1 | – | |

| 2 | 265-295 (soft) | normal load up to 600 min-1 | very high load up to 600 min-1 | |

| 3 | 220-250 (medium firm) | high load up to 400 min-1 | – | – |

AM wiper seals must be used for grease lubrication.

In principle, relubrication is required. Due to the continuous travel of the nut, there will be lubricant loss. Considering aging and contamination, maintenance or renewal of grease quantity is also required.

Relubrication Intervals

Relubrication intervals must be determined in practice for each case, as they depend on other influencing factors such as:

- Load

- Speed

- Temperature

- Environmental conditions

- Mounting position

- Protection of the screw

Lubrication Selection Guide

| Lubrication Type | Advantages | Applications |

|---|---|---|

| Oil Lubrication |

| High-speed applications, high loads, continuous operation |

| Grease Lubrication |

| Intermittent operation, low-speed applications, clean environments |