AMS Read Head Interfaces

Read Head Interfaces

Connector Type Overview

SCHNEEBERGER offers various connector interfaces to accommodate different control systems and application requirements.

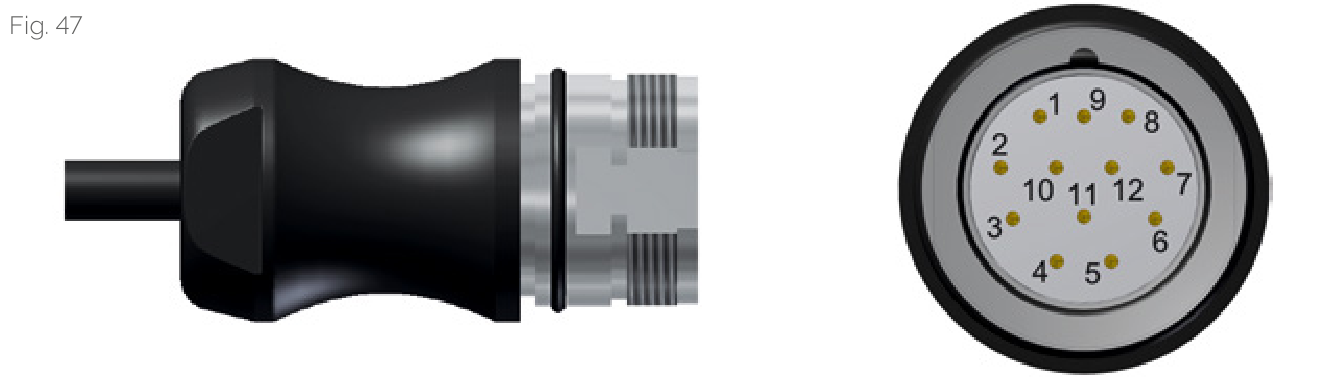

TSU/TSD 12-pin plug

TRU/TRD 12-pin plug

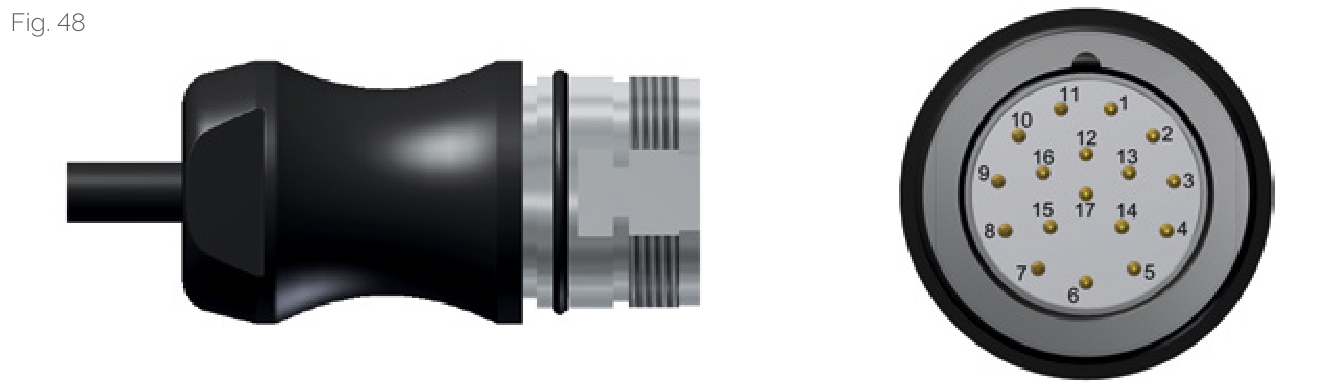

TRH 17-pin plug

TMU/TMD mounting base

TMH 17-pin mounting base

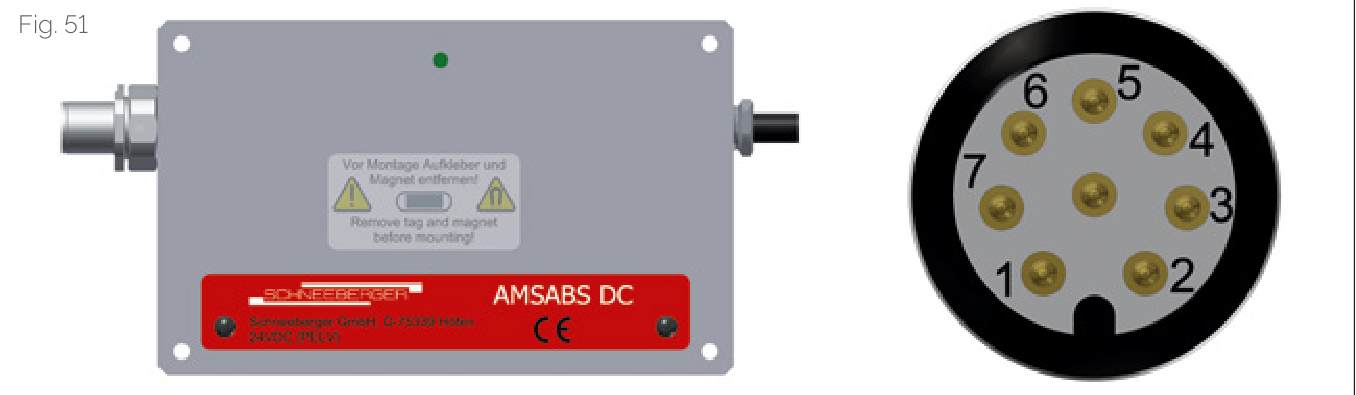

TDC 8-pin electronics housing

| Interface Code | Type | Connector Form | Cable Length |

|---|---|---|---|

| TSU / TSD | 12-pin circular connector (female) | Union nut and female thread | 3m |

| TRU / TRD | 12-pin circular connector (male) | Male thread | 3m |

| TRH | 17-pin circular connector (male) | Male thread | 3m |

| TMU / TMD | 12-pin circular connector (mounting base) | Built in a mounting base | 0.3m |

| TMH | 17-pin circular connector (mounting base) | Built in a mounting base | 0.3m |

| TDC | 8-pin circular connector (male) | Male thread built into electronics housing | - |

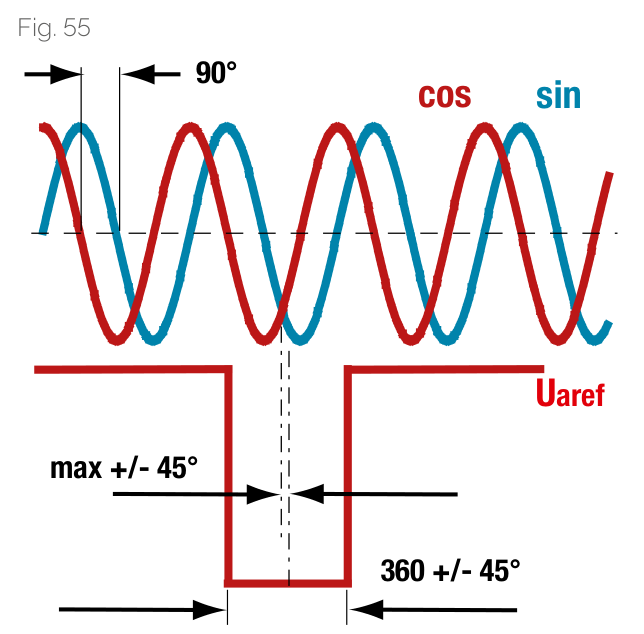

TSU/TRU/TMU Analog Interface

Incremental signals are displayed as differential (voltage signals relative to ground), and the accuracy class defines the relationship between incremental signals and reference signals R1-R5.

Analog voltage interface signal waveform

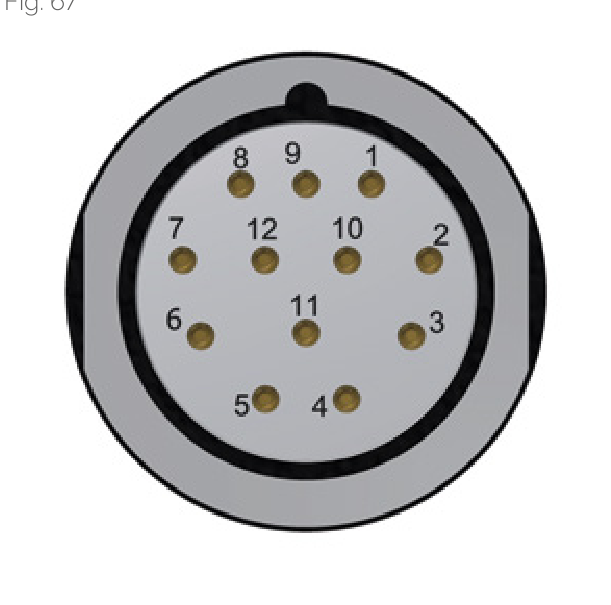

TSU/TRU/TMU pinout

Pinout Configuration

| Pin | Signal | Description |

|---|---|---|

| 1 | 0V | A quasi B signal |

| 2 | - | Supply voltage feedback |

| 3 | +UA0 | Reference signal |

| 4 | -UA0 | Reference signal (synchronous) |

| 5 | +UA | A quasi B signal |

| 6 | -UA | Sine |

| 7 | +UB | A quasi B signal |

| 8 | -UB | +Cosine |

| 9 | - | NC |

| 10 | 0V GND1 | Supply voltage |

| 11 | 0V | Supply voltage feed back |

| 12 | 0V+ | Supply voltage feed back |

TSD/TRD/TMD Digital Interface

Incremental signals A+, A-, B+, B- and reference signals R+, R- transmit data in a complementary manner according to RS 422 standard. The diagram shows positive signals, with signal levels as follows:

| High | > 2.5 V |

| Low | < 0.5 V |

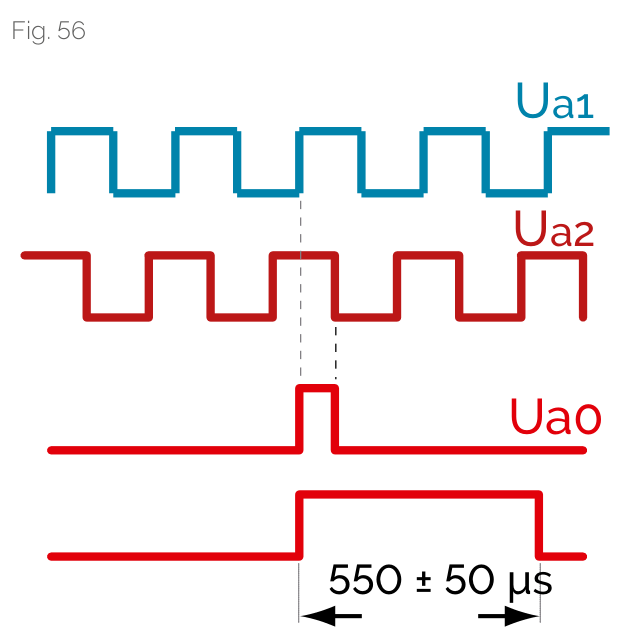

Digital interface timing diagram

TRD/TMD pinout

Rise and fall times are less than 20 ns. Minimum signal spacing can be calculated from the maximum output frequency. Downstream electronics must be able to handle the maximum output frequency without problems.

Reference Pulse Options

Option ZN

Reference pulse is strictly synchronized with incremental signal.

Option ZF

Reference pulse is extended to 550 us +/- 50 us. This option is suitable for evaluation electronics that cannot handle multiple short-duration reference pulses.

Interpolation Factor, Maximum Output Frequency, and Reference Pulse Combinations

The following combinations apply to all read head interfaces:

| Code | Resolution | Interpolation Factor | Max Output Frequency |

|---|---|---|---|

| -010-80-ZN | 5 um | 10x | 8 MHz |

| -050-80-ZN | 1 um | 50x | 8 MHz |

| -250-80-ZN | 0.2 um | 250x | 8 MHz |

| -010-80-ZF | 5 um | 10x | 8 MHz |

| -050-80-ZF | 1 um | 50x | 8 MHz |

| -250-80-ZF | 0.2 um | 250x | 8 MHz |

Order Code Example

-010-80-ZN- 10x interpolation, maximum output frequency 8 MHz, standard reference pulse

TSD/TRD/TMD Pinout Configuration

| Pin | Signal | Function |

|---|---|---|

| 1 | +24 V | Power supply (positive) |

| 2 | TXD (service only) | Communication with service program |

| 3 | RXP | Receive data + |

| 4 | RXN | Receive data - |

| 5 | GND (0V) | Power supply (negative) |

| 6 | TXN | Transmit data - |

| 7 | TXP | Transmit data + |

| 8 | RXD (service only) | Communication with service program |

Absolute Interfaces TRH / TMH / TSH

Absolute position information can be transmitted via fully digital interfaces or hybrid interfaces.

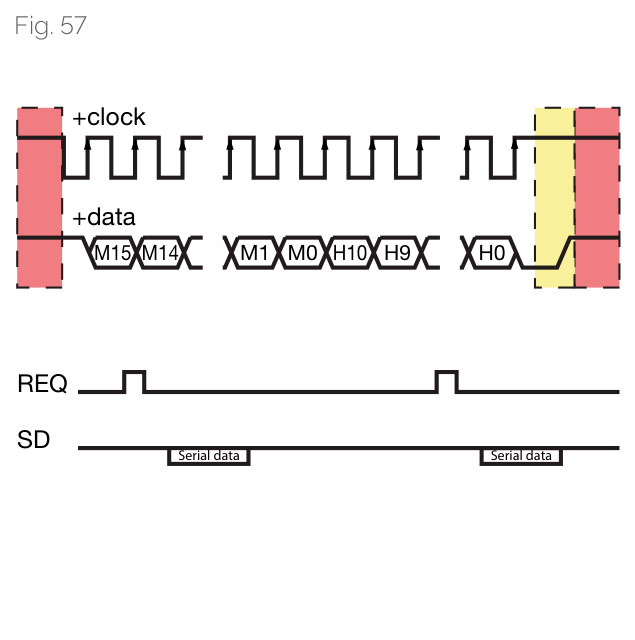

TRH/TMH/TSH interface timing diagram

TRH/TMH/TSH pinout

Fully Digital SSI Interface

In the fully digital SSI interface, the first channel (+clock) sends clock signals from the receiver to the measuring system; the second channel (+data) simultaneously sends absolute position values from the measuring system to the downstream electronic unit.

Fanuc Serial Interface

Another fully digital interface example is the "Fanuc Serial Interface." The motor controller only sends a request signal (REQ) instead of pulses. The measuring system calculates the clock rate accordingly, which is used to send position data and supplementary data (SD) to the receiver.

SSI+SinCos Hybrid Interface

The SSI+SinCos hybrid interface only sends digital absolute initial position at power-on, then sends incremental 1 Vpp signals.

Interface Compatibility

- SSI Interface: Can connect to any commercial controller with SSI interface

- Fanuc Serial Interface: Designed specifically for Fanuc controllers

- SSI+SinCos Interface: Designed specifically for Siemens controllers

TRH/TMH Pinout Configuration (SSI / Fanuc / Mitsubishi Interface)

| Pin | Signal | Signal Type |

|---|---|---|

| 1 | A+ | A quasi B signal / SSI(pos) feedback |

| 2 | NC | - |

| 3 | 0V (sens) | Supply voltage feedback |

| 4 | RQ | Internal use/maintenance |

| 5 | NC | - |

| 6 | +5 to 24V | Supply voltage |

| 7 | CLK+ | - |

| 8 | CLK- | - |

| 9 | +UB | +Cosine |

| 10 | -UB | -Cosine |

| 11 | +UA | +Sine |

| 12 | -UA | -Sine |

| 13 | A- | Supply voltage |

| 14 | DATA+ | - |

| 15 | DATA- | - |

| 16 | 0V | Gnd |

| 17 | 0V(+) | - |

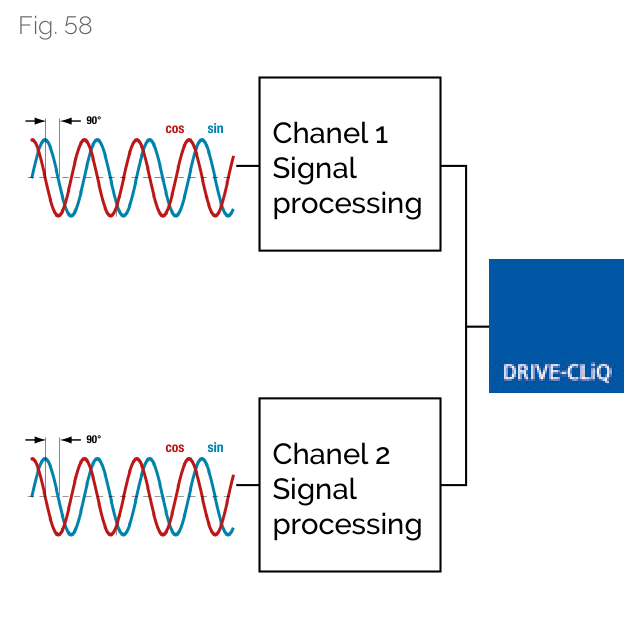

Absolute Interface TDC (DRIVE-CLiQ)

Absolute information from the measuring system is transmitted via the DRIVE-CLiQ communication interface, a real-time serial interface for bidirectional data transmission with Siemens controllers.

TDC DRIVE-CLiQ interface

TDC pinout diagram

The measuring system connection is suitable for safety-oriented applications and supports the SAFETY INTEGRATED function available for Siemens SINAMCS and SINUMERIK controllers. The system complies with IEC 61508-1:2010 functional safety requirements.

DRIVE-CLiQ is a registered trademark of Siemens

TDC Pinout Configuration

| Pin | Signal | Function |

|---|---|---|

| 1 | GN+ | Power supply positive |

| 2 | GND(M) (sensor only) | - |

| 3 | RXD- | Received data |

| 4 | RXD+ | - |

| 5 | GND (DC) | Power supply negative |

| 6 | TXD- (M) (sensor only) | - |

| 7 | TXD+ | Sent data |

| 8 | - | Communication with service program |