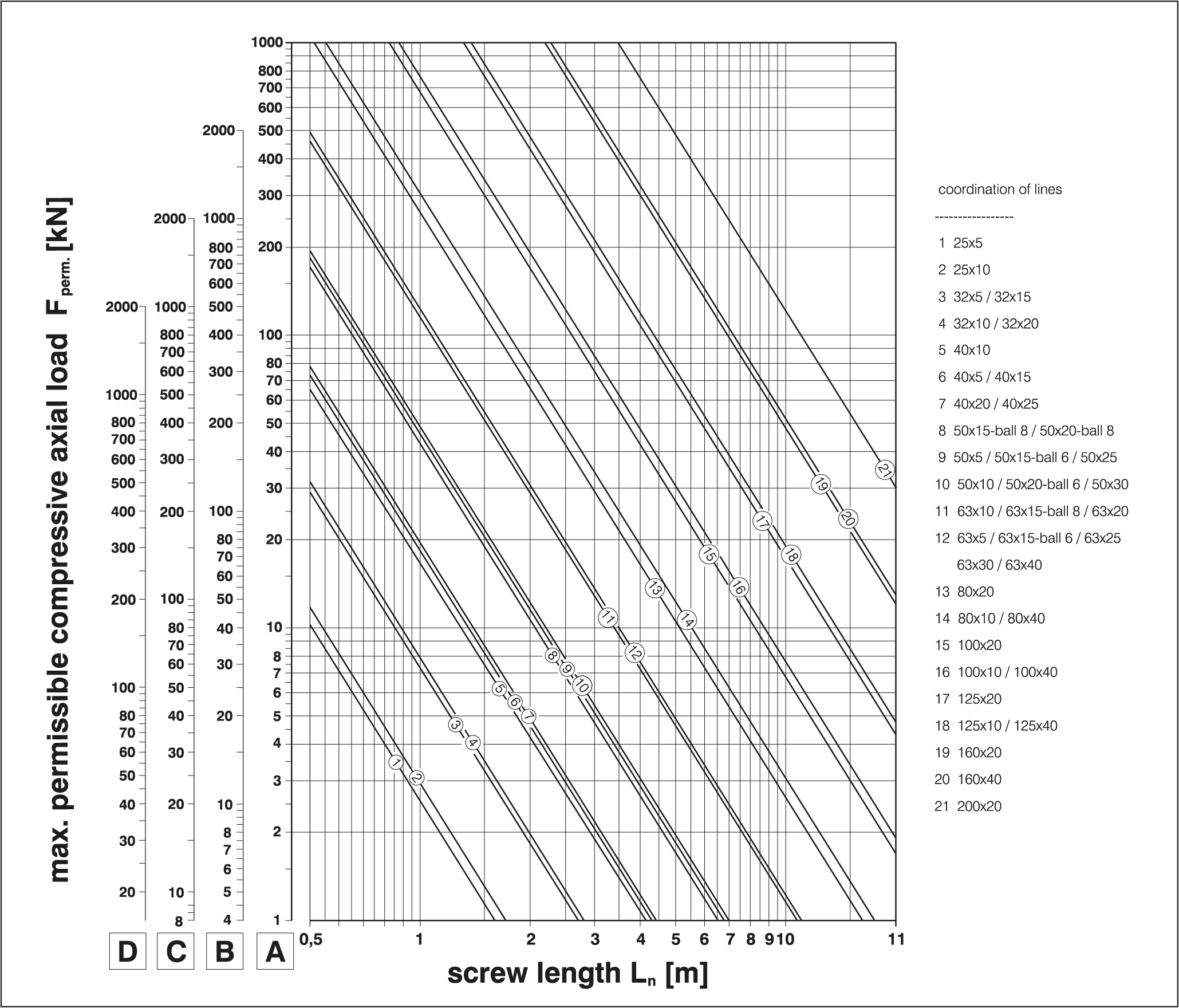

Permissible Compressive Axial Load Fperm

Permissible Compressive Axial Load

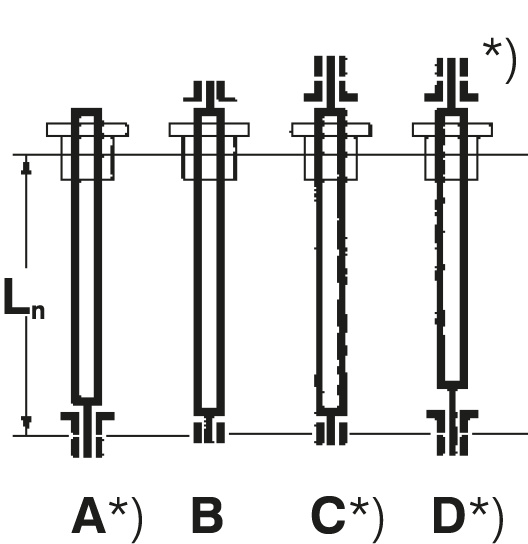

*) Directionally stable mounting

Bearing Arrangement Types

The permissible axial load can be determined from the chart based on screw bearing arrangement, nominal diameter d0 × lead P, and screw length Ln.

For compressive axial load Fk, the chart includes a threefold safety factor (ν = 3).

The static load rating C0am is the load limit that causes plastic deformation of 10-4 × ball diameter under static conditions.

See data sheets for C0am

Steps for Increasing the Permissible Compressive Axial Load

Steps for Increasing the Permissible Compressive Axial Load

Use Bearing Arrangement D

Double-end fixed arrangement provides the highest axial load capacity

Apply Tensile Load

Apply tensile load to the screw in arrangement A or C cases

Increase Nominal Diameter

Larger diameter can withstand higher compressive loads

Reduce Compressive Load

Share load through hydraulic or counterweight methods

Bearing Arrangement Reference Table

Bearing Arrangement Reference

| Arrangement | Description | Characteristics |

|---|---|---|

| A | Fixed-Free | Suitable for shorter screws |

| B | Fixed-Supported | Medium load capacity |

| C | Supported-Supported | Allows thermal expansion |

| D | Fixed-Fixed | Highest axial load capacity |