When applications require guideway systems exceeding the maximum length of single-part guide rails, SCHNEEBERGER MONORAIL provides combined guide rail solutions. This chapter introduces the characteristics of combined guide rails, butt joint design, and installation and marking methods.

4.10.1 Combined Guide Rails and Butt Joints

The length L3 of SCHNEEBERGER MONORAIL single-part guide rails is limited by production equipment to a maximum of 6 meters. For maximum lengths, see the respective product descriptions. If longer guide rails are required, they can be joined from two or more guide rail segments. After the guide rail segments are fixed, they form a gap-free, fully loadable butt joint.

Advantages of Combined Guide Rails

Extended Travel

Overcomes single-part guide rail length limitations to achieve longer travel distances.

Gap-Free Design

Butt joint design ensures no gaps between guide rail segments, providing continuous rolling contact surfaces.

Full Load Capacity

When correctly installed, butt joints can bear the same load as standard guide rails.

Flexibility

Multiple guide rail segments can be combined according to application requirements to accommodate various installation environments.

Butt Joint Characteristics

- Guide rail segments are precisely butted to ensure smooth passage of rolling elements

- Butt joints undergo special machining to ensure geometric accuracy

- Using fixing bridges enables precise alignment

- Applicable to N, NU, NUD, C, and CD type guide rails

4.10.2 Installation and Marking

Multi-part guide rails are marked with numbers at the butt joints, and GP models are also marked with group numbers at the guide rail starting end.

Guide rail joint numbering and group marking. Marking 1.1 applies only to GP designs.

Marking System Description

Marking Meanings:

- Group Number Index: Identifies the guide rail group (GP models only)

- Butt Number: Identifies the connection sequence of guide rail segments

- Number 1: Indicates the reference guide rail, the starting point for installation

Installation Notes

When installing guide rails, ensure that butt numbers match. Guide rails marked with group number index 1 or butt number 1 are reference guide rails.

Important Installation Requirements

- Butt numbers must match in sequence

- Start installation from the reference guide rail (number 1)

- Ensure no gaps at guide rail joints

- Use appropriate alignment tools to ensure accuracy

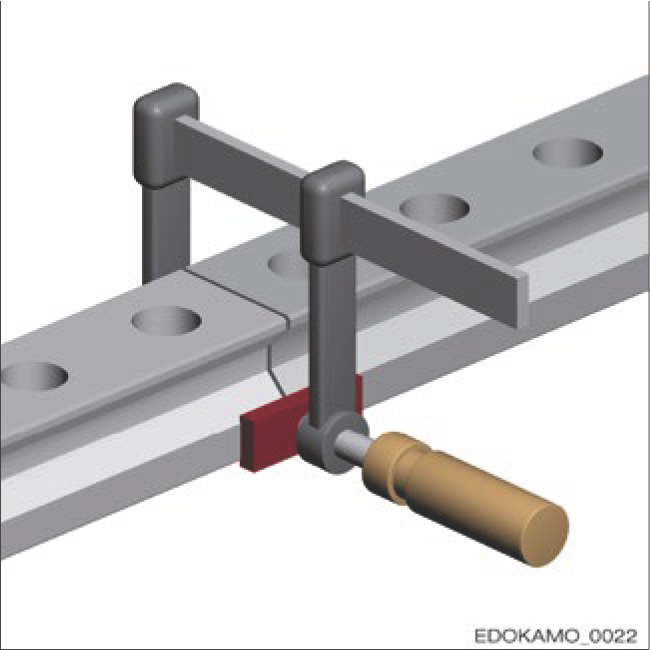

Installation Using Fixing Bridges

When installing multi-part guide rails without locating surfaces on the machine bed, fixing bridges should be used to align guide rail butt joints.

Installation using fixing bridges

Fixing Bridge Installation Method:

- Position the fixing bridge across the butt joint

- Ensure both guide rail segments are correctly aligned

- Tighten fixing screws according to specified torque

- Check for gaps at the butt joint

Installation Using Locating Surfaces

When installing using machine-side locating surfaces, ensure the guide rail's locating surface is in contact with the locating surface. In both cases, attention should be paid to ensuring no gaps at guide rail joints.

Installation Without Locating Surface

- Requires fixing bridges for alignment

- More complex installation

- Requires additional alignment tools

Installation With Locating Surface

- Uses machine locating surface for alignment

- Relatively simple installation

- Accuracy depends on locating surface quality

Replacement and Maintenance

When replacing parts, multi-part guide rails can only be replaced as complete sets. Individual customized parts cannot be ordered later. Individual guide rail parts of N, NU, NUD, C, and CD types are only interchangeable with MONORAIL RSR, BSR, and MONORAIL AMS 3L.

Maintenance Recommendations

- Regularly check alignment at butt joints

- Ensure no abnormal wear at butt joints

- Keep butt joints clean to avoid contaminant accumulation

- Maintain the entire guideway system according to standard lubrication procedures

Ordering Information

Information Required When Ordering Multi-Part Guide Rails:

- Total length requirement

- Number of segments (if specific requirements)

- Guide rail type (N, NU, NUD, C, CD)

- Size specifications

- Accuracy class requirements

- Whether fixing bridges are needed

Important Reminder

Multi-part guide rails are supplied as matched sets, with each guide rail segment machined as a matched pair to ensure butt joint accuracy. Therefore:

- Guide rail segments from different groups cannot be mixed

- Complete sets must be replaced when replacement is needed

- Retain original markings for identification and maintenance

- If spare parts are needed, they should be considered when ordering