AM Deep Nitrided Screw System

The AM ball screw system uses deep nitriding technology for screw processing, combined with ground ball tracks on screws and nuts, providing excellent precision and durability.

Nominal Diameter Range

Diameter Specifications

- Standard Range: 25 to 200 mm

- Diameter/Lead Combinations: According to German standard DIN 69051 Part 2

- Other Leads: Available on request

Thread Length

Length Specifications

- Continuous Thread: Lengths up to 10,000 mm

- Connected Design: Used for lengths exceeding this

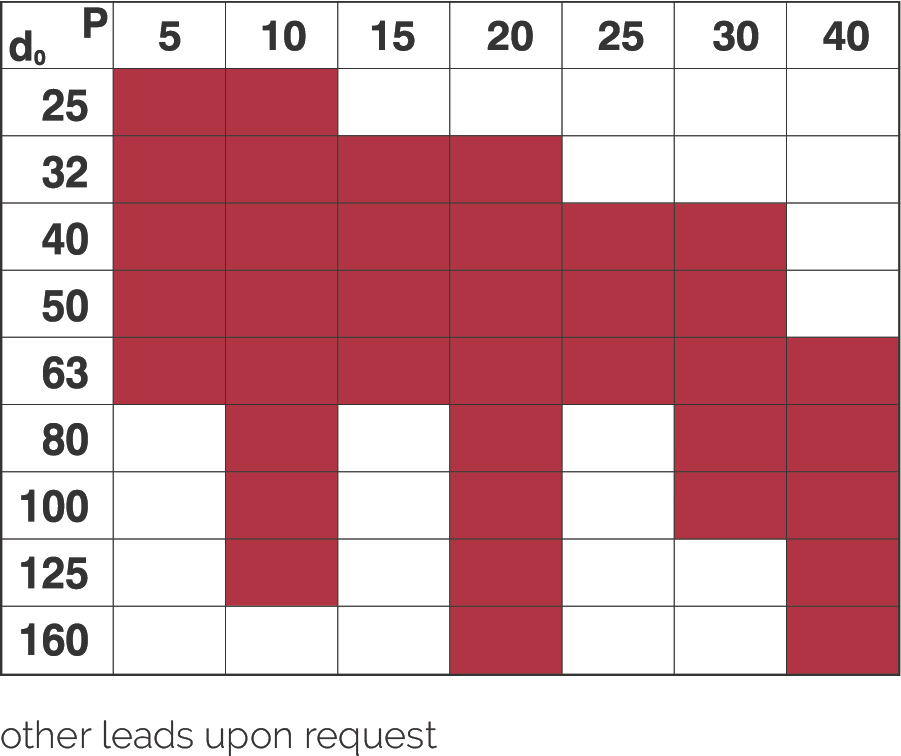

Diameter/Lead Combination Chart

Diameter / Lead Combinations

Red areas in the chart indicate available diameter/lead combinations. Other leads available on request.

Deep Nitriding Technology Advantages

Based on many years of experience, we confidently recommend deep nitrided screws. A hardness of approximately 900 HV (equivalent to Rockwell hardness 67) and the material's high core strength (850-1,000 N/mm²) provide the following advantages:

- Increased Wear Resistance - Significantly improved surface hardness, extended service life

- Increased Fatigue Strength - Can withstand higher cyclic loads

- Long-term Accuracy Consistency - Maintains stable positioning accuracy

- Extended Actual Service Life - Proven long-term reliability

- Corrosion Resistance - Nitrided layer provides good protection

Screw Ends and Bearing Seats

Deep nitrided screw ends and bearing seats ensure:

- Consistent pitch circle diameter and profile dimension accuracy over the entire length

- High surface quality

- Optimal running characteristics

Lead Accuracy

Lead accuracy corresponds to ISO tolerance grades IT1, IT3, IT5, selected according to application requirements.

AM Ball Screw Features

High Quality Performance

- High-Speed Applications - Suitable for high-speed operation

- Highest Resolution Positioning Accuracy - Precise position control

- Highest Dynamic Performance - Suitable for long-term applications