Correct design is the foundation for ensuring long-term reliable bearing operation. This page details the geometric parameters and structural requirements that must be strictly adhered to during the design phase.

Design errors may lead to:

- Premature bearing failure

- Raceway damage (Brinelling)

- Seal failure

- Inability to properly install or remove

1. Key Design Parameter Definitions

The ball bearing tables show the dimensions of the myonic miniature ball bearings. To ensure correct bearing installation and operation, shaft and housing design must strictly adhere to the following dimensional parameters (see product tables):

| Symbol | Definition | Key Design Requirement |

|---|---|---|

| d | Inner diameter | Reference dimension of bearing inner ring bore |

| D | Outside diameter | Reference dimension of bearing outer ring outside diameter |

| B | Width of ball bearing rings | Total width reference dimension of bearing rings |

| Li | Minimum permissible shoulder diameter of housing seat | Must be >= this value to ensure adequate outer ring support without contacting the inner ring |

| Lo | Maximum permissible shoulder diameter of shaft | Must be <= this value to ensure adequate inner ring support without contacting the outer ring |

| r max | Maximum permissible rounding radius | Shaft or housing corner radius must be <= this value to ensure bearing fully seats against shoulder |

| h min | Minimum permissible shoulder height | Shaft or housing shoulder height must be >= this value to provide reliable axial positioning |

2. The Following Should Be Avoided

The following are common design errors that should be avoided:

Figure 1 Radius Too Large

Error: Shaft or housing corner radius r is greater than bearing's r max.

Consequence: Bearing cannot seat tightly against shoulder, axial position unstable; forced installation will cause bearing ring deformation.

Figure 2 & 3 Shoulder Height Insufficient

Error: Shoulder or retaining ring height is less than h min.

Consequence: Insufficient support area, bearing ring may deform or shift axially under load.

Figure 4 Housing Shoulder Diameter Too Small

Error: Housing shoulder diameter De is smaller than specified Li.

Consequence: Housing shoulder contacts the rotating inner ring face, causing severe friction and seizure.

Figure 5 Shaft Shoulder Diameter Too Large

Error: Shaft shoulder diameter de is greater than specified Lo.

Consequence: Shaft shoulder contacts the stationary outer ring face, causing rotational interference.

3. Please Note the Following

Correct design should not only avoid the above errors but also consider the force path during installation and future maintenance convenience.

Figure 6 Key Rule: Force Path

Installation or removal force must act directly on the interference-fitted ring!

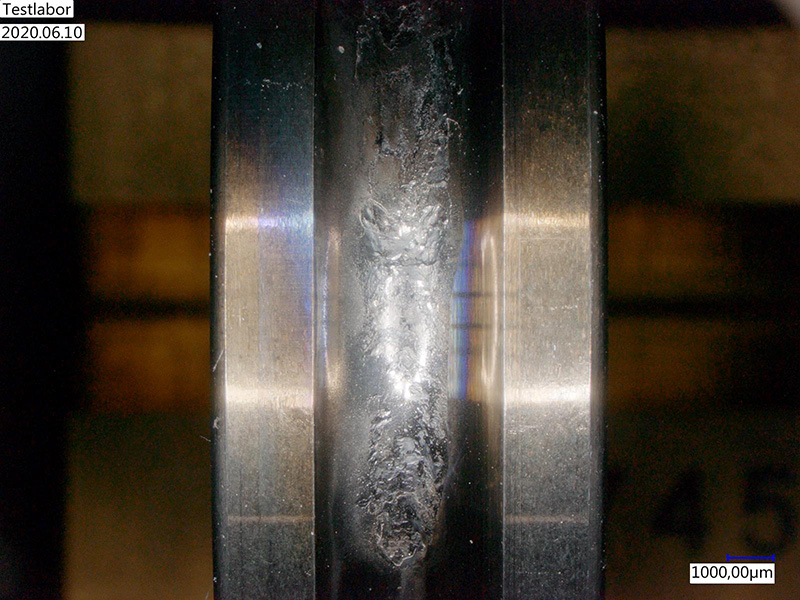

Absolutely forbidden to transmit installation force through rolling elements (balls). This will cause small indentations in the raceway (Brinelling), which is the most common cause of bearing noise and premature failure.

Design for Disassembly

Miniature bearings are often very tight fits. Design must consider how to remove them in the future without damaging surrounding components.

Figure 7 Use Intermediate Rings

Insert intermediate rings (1) between shaft/housing shoulders and bearing. During removal, simply push the intermediate ring to extract the bearing.

Figure 8 Machine Removal Grooves

If space does not allow intermediate rings, removal grooves should be machined into the shaft or housing shoulders to accommodate puller tool hooks.

Figure 9 Ideal Design Structure

This is a design example incorporating all correct parameters:

- Strictly adheres to Li and Lo, no interference anywhere

- Corner radius r < r max, ensures bearing fully seats against shoulder

- Shoulder height h > h min, provides adequate axial support for bearing

- Design includes removal grooves or uses intermediate rings for easy maintenance

Damage Due to Incorrect Handling (Common Cases)

Even with correct design parameters, improper handling and installation procedures can cause permanent bearing damage. The following are typical damage images:

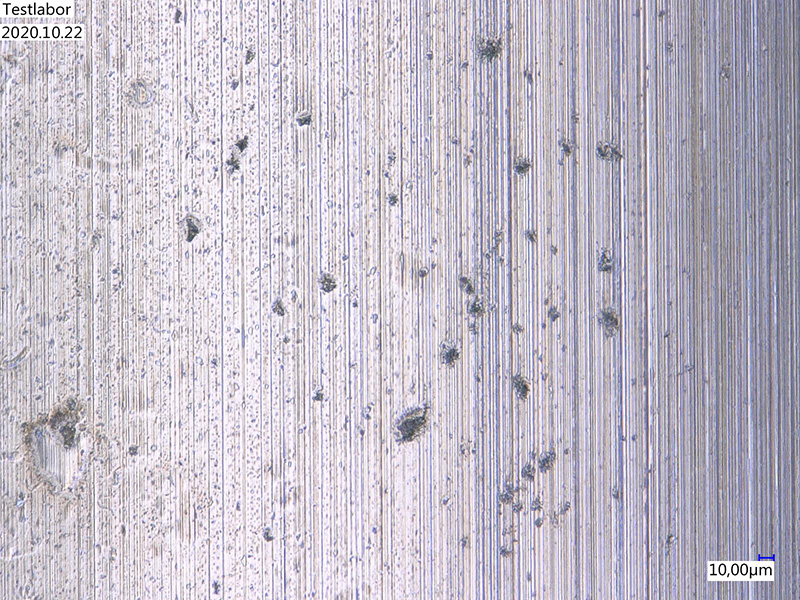

Track damage due to overrolling of foreign particles

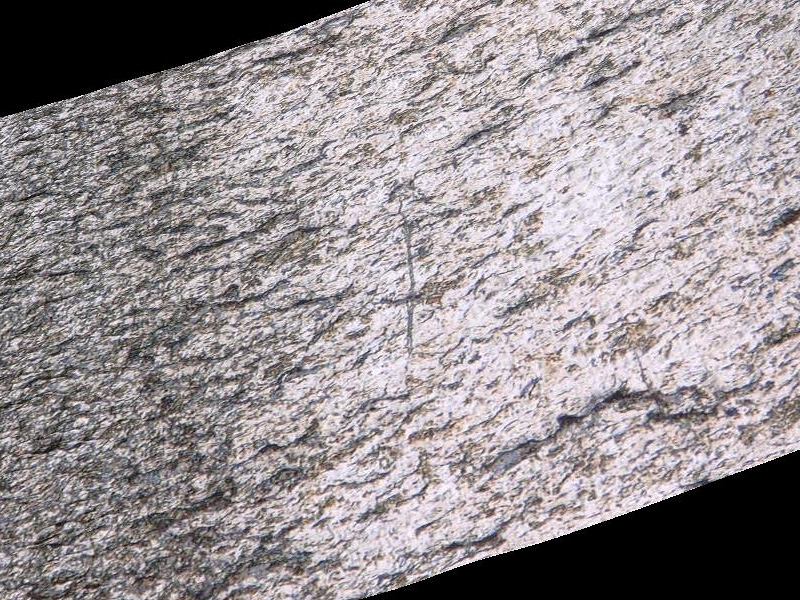

Damage due to lack of lubricant

Raceway overloaded

Technical Consultation

If you have any questions about design or installation, please contact the myonic technical support team.

Our engineers have extensive experience with miniature bearing applications and can provide professional technical guidance and customized solutions.