Assembly Instructions

Gear racks can be assembled to any length. When assembling, the gap between two gear racks must precisely match the pitch. For gear racks shorter than 1 metre, locating pins may be required.

Installation Steps

Align the First Gear Rack

Use a torque wrench to tighten the screws. The torque value depends on friction conditions and the strength class of the screws.

Select the Correct Screws

Use strength class 10.9 screws for soft or induction hardened gear racks. Use strength class 12.9 screws for case hardened and through hardened gear racks.

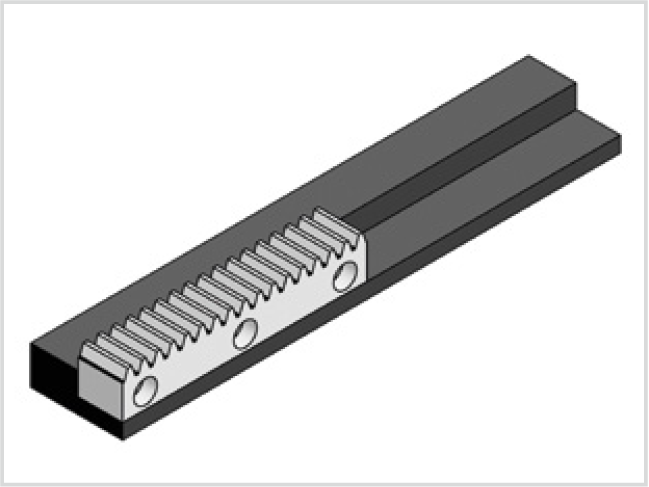

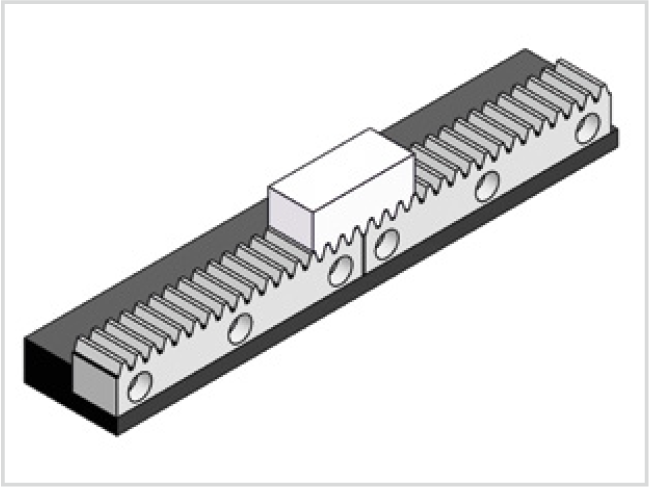

Align the Next Gear Rack

Use an installation plate to align the next gear rack, then tighten the screws.

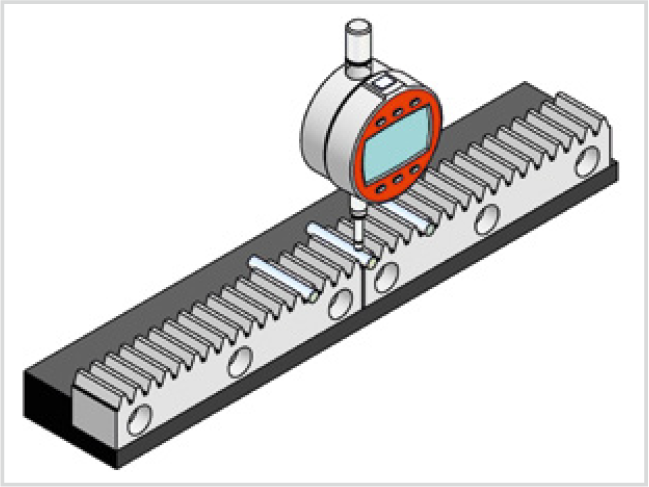

Check Height Deviation

Use a measuring roller to check the height deviation at transition points, and adjust the gear rack position if necessary.

Check Parallelism

Confirm that the gear racks are parallel to each other.

Insert Locating Pins

Finally, insert locating pins if necessary.

Lubrication Instructions

To maintain the functionality of gear rack drives, adequate lubrication with a lubricant suitable for operating conditions is required. Lubrication prevents wear and corrosion, and reduces friction.

Lubrication Key Points

- In addition to initial lubrication during assembly, the machine must be regularly lubricated during operation

- Electric lubrication dispensers are typically used for lubrication

- Use lubricating grease of NLGI 00 to NLGI 0 grade

- Apply lubricating grease to the drive gear or gear rack via a felt gear

- Typical lubricant: Klüber Microlube GB 0

More Information

Detailed installation instructions can be downloaded from:

www.schneeberger.com/downloads