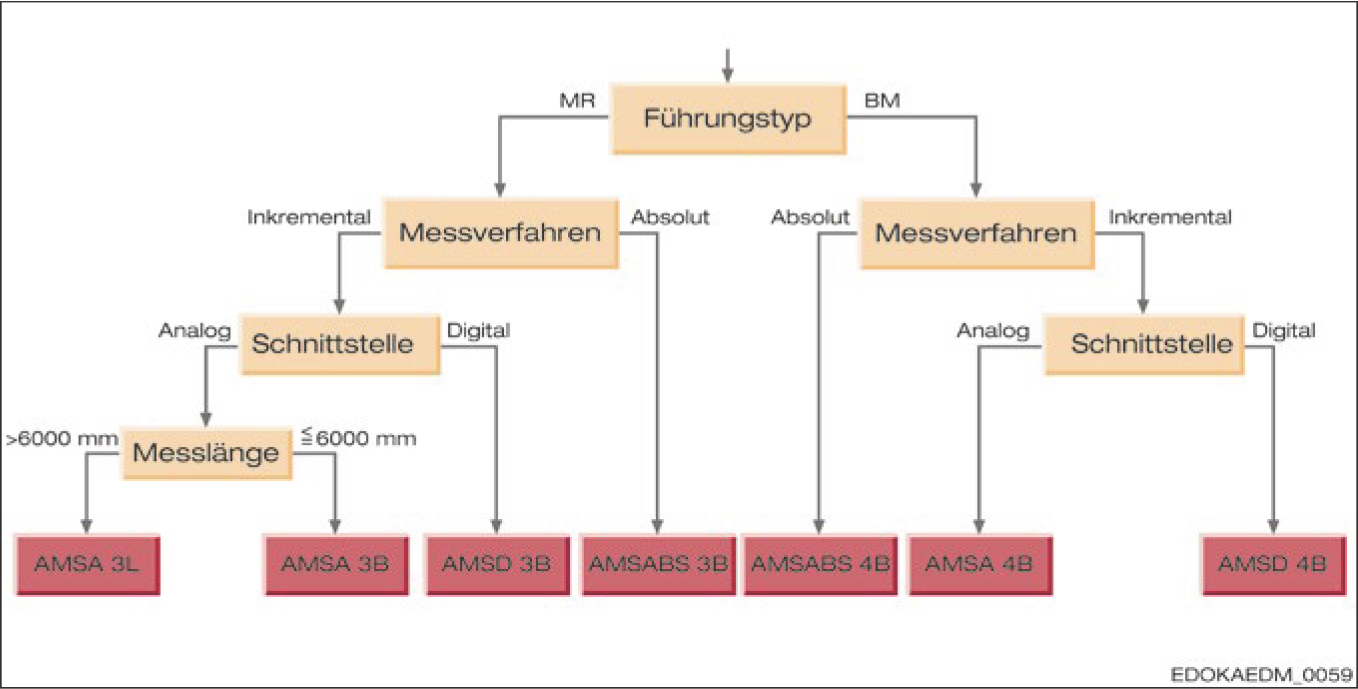

6.3.1 Product Selection

The following factors influence the selection of distance measuring systems:

- Guide rail type: Roller - Ball

- Selection tool can be found in Section 4.2 - Ball - Roller Comparison

- Absolute - Incremental measuring procedure

- Interface, availability see Section 6.2 - Product Overview

- Interface Analog - Digital

- Detailed information can be found in Section 3.2 - Principles

- Accuracy of the measuring system

- Specific details see Section 3.2 - Principles and 6.2 - Product Overview

- Homing procedure

- Different homing procedures are described in Section 3.2 - Principles, availability is listed in Section 6.2 - Product Overview

- Speed

- Depends on the guide rail system used; see Section 6.2 - Product Overview

- Measuring length

- Environmental conditions

- Controller

Measuring Length

The measuring length of a linear distance measuring system is the maximum stroke over which distance information can be obtained. In systems with a specific scale length, it depends on the length of the measuring scale.

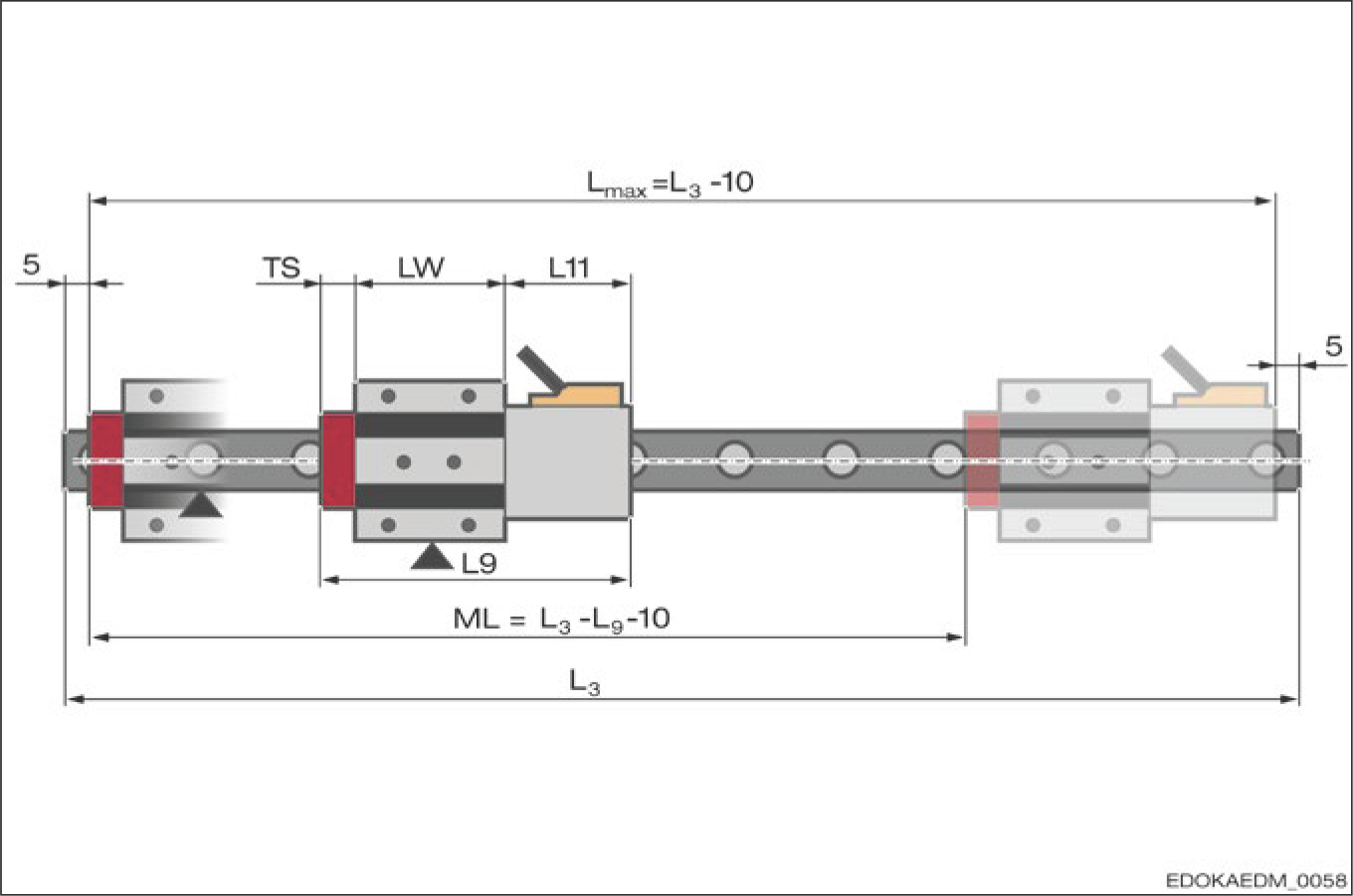

The measuring length ML of MONORAIL AMS is calculated from the guide rail length L3 and the carriage length including reading head housing L9, as shown in the figure below

ML = L3 - L9 - 10 (mm).

Maximum usable length (Lmax = L3 - 10) and measuring length (ML = L3 - L9 - 10):

- Lmax Maximum usable length of the system

- Total carriage length with housing

- ML Measuring length

- Housing length

- Guide rail length

- TS Front plate thickness

- LW Internal carriage body length

For larger measuring lengths, SCHNEEBERGER developed "AMS long". For detailed information on this product, see Section 6.2 - Product Overview and Section 6.7 - Multi-Segment Measuring Guide Rails.

In the case of measuring scales with distance-coded reference marks, the base period determines the maximum encodable length, which in turn limits the measuring length of the measuring system. For these systems, a smaller base period is usually selected for short axes to reduce the maximum travel distance required for the reference stroke. The smaller the base period, the smaller the encodable length. SCHNEEBERGER offers different base periods for its AMS products with distance-coded reference marks.

The following table lists the maximum encodable length Lmax depending on the SCHNEEBERGER standard base period GP.

| Name | GP (mm) | Lmax (mm) |

|---|---|---|

| TD20 | 40 | 2840 |

| TD50 | 100 | 22100 (theoretical)* |

Note: * Limited by maximum guide rail length of 6000mm

Environmental Conditions

When using coolant, compatibility with the lubricant must be checked and subsequent lubrication intervals shortened accordingly. For extended downtime or short strokes, additional strokes covering the entire travel should be provided, so-called lubrication and cleaning strokes. They should prevent adhesion and clogging of coolant. Adhered dirt can affect the function of the measuring system and damage the sensor.

If chips or similar objects occur during operation, sufficient protection should be provided for the measuring system in the form of covers.

Controller

SCHNEEBERGER distance measuring systems can be used with most industrial CNC controllers, such as Siemens SINUMERIK CNC controllers and FANUC CNC controllers.

More detailed information on usable controllers and their specific settings can be obtained from controller manufacturers or through SCHNEEBERGER representatives.