16.3 Installation Preparation

16.3.1 Required Tools and Equipment

- Oilstone

- Lubricant

- Torque wrench

- Fastening screws

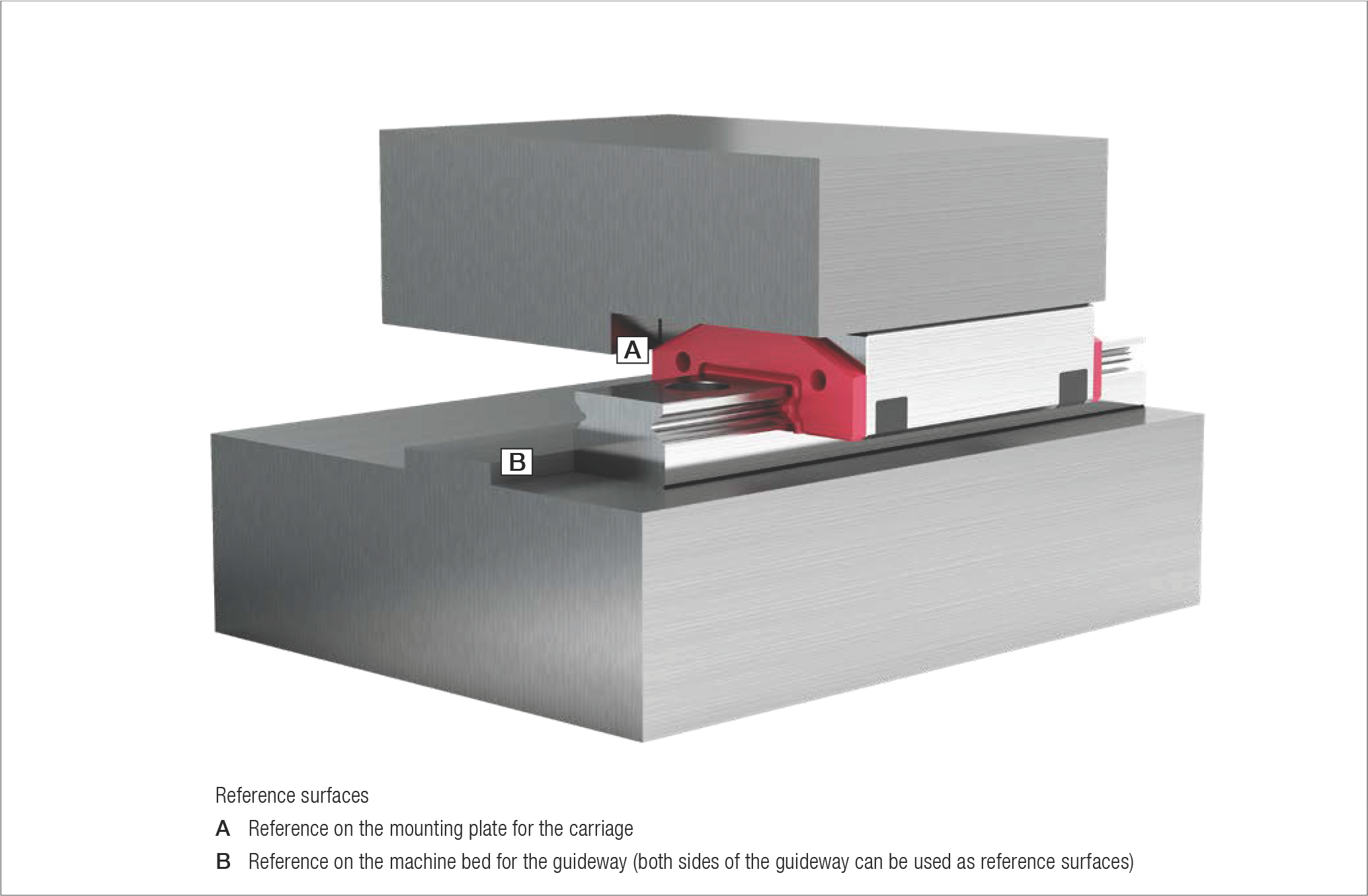

16.3.2 Preparation of Reference Surfaces

- Check the shape and position accuracy of the reference surfaces on the machine bed and mounting plate

- Thoroughly clean all reference surfaces. Use an oilstone to remove protrusions and surface irregularities

- Clean the reference and support surfaces of the guide rail and carriage using mineral spirits or isopropanol. Do not use paint thinner!

- Clean dirty guide rails using a soft, lint-free cloth. Do not use compressed air!

- Lightly apply oil to the reference surfaces of the guide rail and carriage

A Reference surface of carriage on mounting plate

B Reference surface of guide rail on machine bed (both sides of guide rail can be used as reference surface)

16.3.3 Lubrication of MINIRAIL

Initial Lubrication

Unless otherwise specified, the carriage and guide rail are delivered separately (see Chapter 18.1). They are delivered in an unlubricated state and must be lubricated with a suitable lubricant for the application before operation.

A) Oil Lubrication

For oil lubrication, mineral oil CLP (DIN 51517) or HLP (DIN 51524) with viscosity range between ISO VG32 and ISO VG150 according to DIN 51519 is recommended.

Guide Rail:

A thin film of oil should be applied to the guide rail tracks using an oil-soaked lint-free cloth (also applies when using the optional LUBE-S. See Chapter 8.1).

Carriage:

The end caps on the carriage each have two lubrication holes (see Chapter 7.1.8), so the left and right ball circulation channels can be lubricated separately. During lubrication, the carriage should be moved along the entire length of the guide rail to apply the lubricant to both the carriage and guide rail. Ensure both tracks are properly lubricated.

Relubrication kit (MNW), capacity 7 ml

A relubrication kit with KLÜBER Structovis GHD can be ordered from SCHNEEBERGER, part number MNW.

B) Grease Lubrication

For grease lubrication, grease KP2K or KP1K according to DIN 51825 is recommended.

Guide Rail:

A thin layer of grease should be applied to the guide rail tracks using a lint-free cloth (also applies when using the optional LUBE-S. See Chapter 8.1).

Carriage:

The following amounts of grease should be applied to the ball bearings using an applicator.

| Carriage Type | Size 7-15 | Size 14-42 | ||||||

|---|---|---|---|---|---|---|---|---|

| 7 | 9 | 12 | 15 | 14 | 18 | 24 | 42 | |

| Short Carriage | ||||||||

| Model | MNNS 7 | MNNS 9 | MNNS 12 | MNNS 15 | — | |||

| Grease amount (cm³) | 0.03 | 0.05 | 0.09 | 0.16 | — | |||

| Standard Carriage | ||||||||

| Model | MNN 7 | MNN 9 | MNN 12 | MNN 15 | MNN 14 | MNN 18 | MNN 24 | MNN 42 |

| Grease amount (cm³) | 0.04 | 0.09 | 0.15 | 0.25 | 0.05 | 0.11 | 0.20 | 0.33 |

| Long Carriage | ||||||||

| Model | MNNL 7 | MNNL 9 | MNNL 12 | MNNL 15 | MNNL 14 | MNNL 18 | MNNL 24 | MNNL 42 |

| Grease amount (cm³) | 0.05 | 0.11 | 0.20 | 0.35 | 0.07 | 0.14 | 0.26 | 0.45 |

| Extra Long Carriage | ||||||||

| Model | MNNXL 7 | MNNXL 9 | MNNXL 12 | MNNXL 15 | — | |||

| Grease amount (cm³) | 0.07 | 0.14 | 0.26 | 0.45 | — | |||

After applying grease to the ball bearings, the carriage should be moved along the entire length of the guide rail to apply the lubricant to both the carriage and guide rail.

Relubrication Intervals

Relubrication intervals depend on many variables such as load, working environment, speed, etc., and therefore cannot be calculated. The lubrication points should therefore be observed over an extended period of time.

A) Relubrication with Oil

A relubrication kit with KLÜBER Structovis GHD can be ordered from SCHNEEBERGER, part number MNW.

Relubrication kit (MNW), capacity 7 ml

The two lubrication holes on the end cap allow direct oil lubrication of the ball circulation channels (see Chapter 7.1.8). Ensure both tracks are properly lubricated.

During lubrication, the carriage should be moved along the entire length of the guide rail to apply the lubricant to both the carriage and guide rail.

B) Relubrication with Grease

A thin layer of grease should be applied to the guide rail tracks using a lint-free cloth. The carriage should then be moved along the entire length of the guide rail to apply the lubricant to the ball bearings and distribute it along the guide rail.

16.3.4 Lubrication of MINISCALE PLUS

Please refer to the MINISCALE PLUS installation instructions in the download section of the SCHNEEBERGER website (www.schneeberger.com).