1.4.1 Function of Preload

SCHNEEBERGER MONORAIL guideways exhibit elastic deformation behavior that is not linear but degressive. This means the rolling elements are relatively soft under minimal force and become stiffer as force increases. The guideway is preloaded, so some of the elastic deformation has already been eliminated. The result is increased overall system rigidity.

SCHNEEBERGER MONORAIL guideways are preloaded to ensure that profiled rail guideways maintain zero clearance even when subjected to force. This means the rolling elements do not lift off from the raceways. Otherwise, due to preload, system rigidity would be affected, which in turn affects the push force FV and service life.

Effects of Preload

- Changes rigidity: and thereby also the natural frequency of the guiding system

- Affects stroke pulsation: periodic motion variation of the carriage

- Increases displacement resistance: improves carriage resistance to displacement

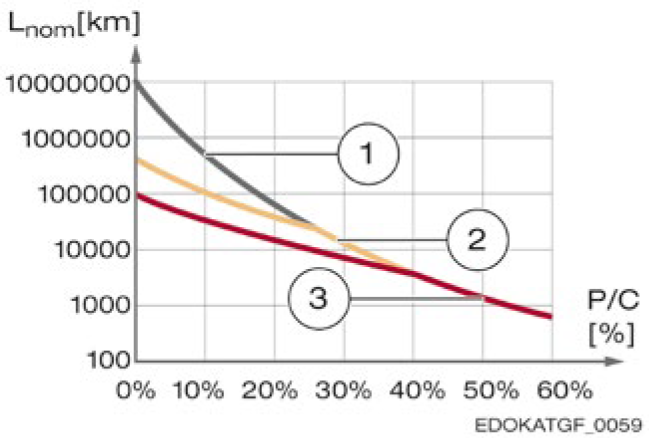

- Affects service life: increases load on the carriage, thereby reducing nominal service life. When calculating life, preload must be included as an additional force

Therefore, preload selection is always a compromise between rigidity, displacement resistance, and service life, which needs to be weighed according to the application. For this purpose, SCHNEEBERGER offers four different preload classes V0, V1, V2, and V3.

Nominal service life as a function of preload and force based on the example of an MR 45 roller guideway. Ratio P/C (%) with equivalent force P (N) and dynamic load capacity C (N) plotted against nominal service life Lnom (km). 1=low preload 2=medium preload 3=high preload

1.4.2 Preload Classes

SCHNEEBERGER offers four different preload classes for different requirements, ranging from 0 - 13% of dynamic load capacity C. Preload class tolerance is ± 3% C. Detailed values can be found in the SCHNEEBERGER MONORAIL and AMS product catalog.

V0 - Very Low/Minimal Clearance

0% or minimal clearance

Only available for MONORAIL BM (ball) series

V1 - Low Preload

Approximately 2-3% of dynamic load capacity C

High-speed motion, low load, extended life

V2 - Medium Preload

Approximately 5-8% of dynamic load capacity C

Standard applications, balanced rigidity and life

V3 - High Preload

Approximately 10-13% of dynamic load capacity C

High rigidity, precision machining, machine tool applications

Product Series Correspondence

- MONORAIL MR (roller) series: Offers three preload classes V1, V2, V3 (low, medium, high preload)

- MONORAIL BM (ball) series: Additionally offers V0 class, where preload can vary between very low preload and minimal clearance

Generation of Preload

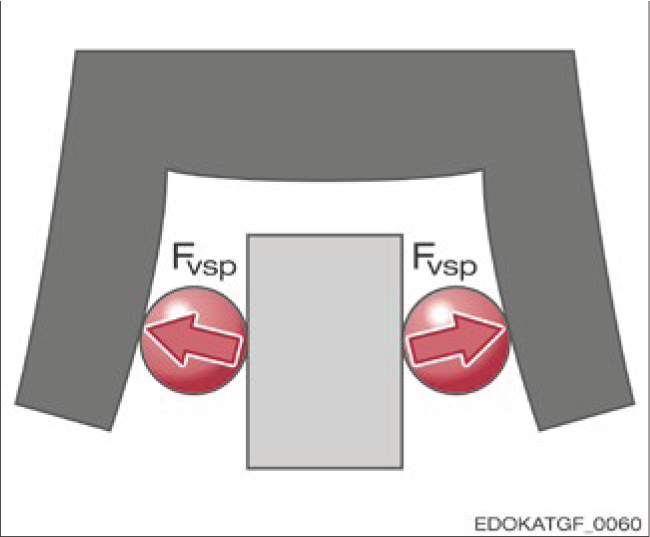

Preload V in the carriage is generated by using oversized rolling elements. This means the diameter of the rolling elements is a few micrometers larger than the clearance between the guideway and carriage. Therefore, when the carriage is pushed onto the guideway, the carriage flanks flex. Preload is caused by the restoring force elastically generated by the carriage body. The magnitude of preload force is set by selecting the appropriate rolling element diameter.

Preload force Fvsp generated by rolling elements, which acts against the carriage. The figure shows a finished ground carriage top.

1.4.3 Effect of Preload on Performance

Rigidity and Vibration Behavior

The amplitude of a low-damping system depends on the ratio of excitation frequency to natural frequency. Higher rigidity increases natural frequency and reduces static deflection. In machine tools, the goal is to achieve high natural frequency so that amplified amplitude remains as small as possible under specified excitation force and frequency.

Conclusion: Use roller guideways with high preload class.

Effective Preload Range

For external loads less than 3 times the preload force, preload is maintained under load. This means the system has high rigidity. If external force exceeds the preload force value, rigidity decreases. Therefore, in designs requiring higher rigidity, it is necessary to ensure staying within the effective preload force range.

Design Key Point

When external force F < 3 × Fvsp (preload force), the system maintains high rigidity.

When external force exceeds this threshold, rigidity decreases significantly.

Service Life Considerations

Preload class also affects guideway service life. Preload V1, V2, or V3 not only increases rigidity, but also loads the rolling contact surfaces as long as preload is effective. When calculating life, preload force must be included in equivalent load calculation as an additional force.

Factors affecting service life include: forces acting on MONORAIL carriage, selected preload, dynamic load capacity, and event probability. If constant force acts over the entire travel distance, equivalent force P is used to calculate life. However, if varying forces are expected, dynamic equivalent force Pj must be used.

Selection Recommendation

When selecting preload class, rigidity requirements, motion speed, load conditions, and life requirements should be comprehensively considered. For detailed selection guide, please refer to Section 4.5 - Preload.

1.4.4 Preload Adjustment and Interchangeability

Preload Measurement and Inspection

Preload not only causes the carriage flanks to expand but also produces a slight depression on the carriage top. This deformation of the top is proportional to the magnitude of preload force and can therefore be used for measuring and inspecting preload.

Installation Note

To ensure the carriage maintains the preset preload after installation, the flatness specifications of the connecting structure specified in this manual must be observed. Otherwise, preload loss or preload increase may occur due to carriage deformation when tightening screws.

Carriage Interchangeability

A feature of SCHNEEBERGER MONORAIL guideways is that regardless of preload, carriages have a level carriage top on any guide rail. Carriages with different preloads can be used on any guide rail. The set preload always remains unchanged.

MONORAIL carriages and guide rails are manufactured independently with extremely high precision, and are therefore fully interchangeable. This means any carriage can be used on any rail of the same size without affecting the preload class, because preload is determined by the rolling elements of the carriage.

Carriage Replacement

Carriages of the same size can be replaced, and preload is maintained. Depending on type, carriages have different screw hole patterns. Carriage types A and B are exceptions. Although they have different lengths, they have the same drilling pattern and are therefore interchangeable. For example, short type (A) and long type (B) carriages can be interchanged without modifying the machine slide. This is not possible for all other carriage types.