MONORAIL BZ Accessories

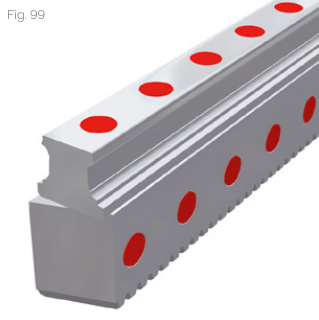

Accessories for Integrated Linear Guide with Rack

Accessories Overview

MONORAIL BZ series accessories include drive pinions, lubrication accessories, sealing elements, and more, ensuring stable system operation and extended service life.

BZ Guide Rail Accessories

| Accessory | BZ S 25 | BZ S 35 |

|---|---|---|

| Plugs: | ||

| Plastic plugs | BRK 25 | BRK 35 |

| Pinions: | ||

| Pinion with through bore | BZR 25-... | BZR 35-... |

| Pinion with through bore and with keyway | BZR 25-...-K | BZR 35-...-K |

| Pinion with shaft | BZR 25-S-... | BZR 35-S-... |

| Pinion with shaft and with keyway | BZR 25-S-...-K | BZR 35-S-...-K |

| Others: | ||

| Lubricating pinion | BZR 25-L-...-K | BZR 35-L-... |

| Pinion hub for lubricating pinion | BZR 25-LN | BZR 35-LN |

| Assembly fixture for BZ systems | BZM 25-... | BZM 35-... |

BM Carriage Accessories

| Accessory | BM W 25 | BM W 35 |

|---|---|---|

| Additional wipers: | ||

| Additional wipers Viton | ZBV 25 | ZBV 35 |

| Metal wiper | ABM 25 | ABM 35 |

| Bellows: | ||

| Bellows | FBB 25 | FBB 35 |

| Adapter plate for bellows | ZPB 25 | ZPB 35 |

| End plate for bellows | EPB 25 | EPB 35 |

| Others: | ||

| Assembly rails | MBM 25 | MBM 35 |

| Lubrication plates | SPL 25-BM | SPL 35-BM |

| Cross wiper for front plate (spare part) | QAS 25-STB | QAS 35-STB |

Plastic Plugs

Protects the fixing holes on the BZ guide rail end face. Standard supply unit is 25 pieces.

| Order Code | Name | BZ 25 | BZ 35 | Description |

|---|---|---|---|---|

| BRK xx | Plastic plugs | BRK 25 | BRK 35 | 25 pcs/pack |

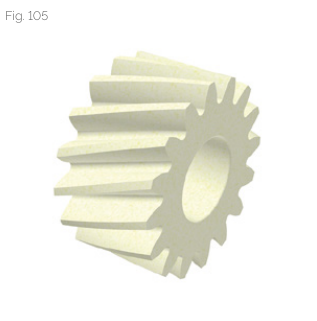

Drive Pinions

The BZ series offers various pinion configuration options selectable based on application requirements. Pinions are case-hardened and ground, quality grade 6.

| Order Code | Name | BZ 25 | BZ 35 | Description |

|---|---|---|---|---|

| BZR xx-m-z-S6 | Pinion with through bore | BZR 25-2.0-20-S6 | BZR 35-2.5-20-S6 | Bore unfinished, can be machined by customer |

| BZR xx-m-z-S6-K | Pinion with through bore and keyway | BZR 25-2.0-20-S6-K | BZR 35-2.5-20-S6-K | Per DIN 6885-A specification |

| BZR xx-S-m-z-S6 | Pinion with shaft | BZR 25-S-2.0-20-S6 | BZR 35-S-2.5-20-S6 | Integrated flat shaft, shaft unfinished |

| BZR xx-S-m-z-S6-K | Pinion with shaft and keyway | BZR 25-S-2.0-20-S6-K | BZR 35-S-2.5-20-S6-K | Per DIN 6885-A specification |

| BZR xx-L-m-z-S | Lubricating pinion | BZR 25-L-2.0-16-S | BZR 35-L-2.5-16-S | Felt pinion for rack lubrication |

| BZR xx-LN | Pinion hub for lubricating pinion | BZR 25-LN | BZR 35-LN | Used with lubricating pinion |

| BZM xx-m-z-S5 | Assembly fixture for BZ systems | BZM 25-2.0-7-S5 | BZM 35-2.5-6-S5 | For aligning butt-jointed BZ rails |

Order Code Explanation

- xx = Size (25 or 35)

- m = Module (2.0 or 2.5)

- z = Number of teeth

- S6 = Quality grade 6

- K = With keyway

- S = With shaft

- L = Lubricating type

Pinion Dimensions Table

| Parameter | Description | BZR 25 | BZR 35 | BZR 25-K | BZR 35-K | BZR 25-S | BZR 35-S | BZR 25-S-K | BZR 35-S-K |

|---|---|---|---|---|---|---|---|---|---|

| z | Number of teeth | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| m | Module | 2.0 | 2.5 | 2.0 | 2.5 | 2.0 | 2.5 | 2.0 | 2.5 |

| alpha | Helix angle | 19 31'42" | |||||||

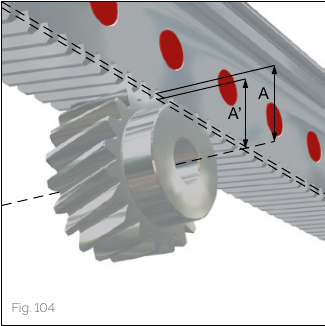

| A | Axis to pitch circle distance | 21.22 | 26.53 | 21.22 | 26.53 | 21.22 | 26.53 | 21.22 | 26.53 |

| A' | Axis to tooth tip distance | 19.22 | 24.03 | 19.22 | 24.03 | 19.22 | 24.03 | 19.22 | 24.03 |

| BT | Tooth width | 20 | 25 | 20 | 25 | 20 | 25 | 20 | 25 |

| DK | Outside diameter | 46.44 | 58.05 | 46.44 | 58.05 | 46.44 | 58.05 | 46.44 | 58.05 |

| D0 | Reference diameter | 42.44 | 53.05 | 42.44 | 53.05 | 42.44 | 53.05 | 42.44 | 53.05 |

| D1 | Shoulder diameter | 35 | 40 | 35 | 40 | 32 | 32 | 32 | 32 |

| D2 | Bore/Shaft diameter | 15 | 15 | 15 | 15 | 25 | 25 | 25 | 25 |

| LR | Total length | 30 | 37 | 30 | 37 | 140 | 145 | 140 | 145 |

| LR1 | Shaft length | 10 | 12 | 10 | 12 | 120 | 120 | 120 | 120 |

Notes

- Above values are standard specifications for z=20 teeth; other tooth counts can be calculated using formulas

- Reference diameter D0 = z x m / cos(alpha)

- Outside diameter DK = D0 + 2m

Lubricating Pinion

Felt lubricating pinion can be used to lubricate the rack. Grease can be manually replenished or connected to an automatic lubrication system.

Pinion Hub for Lubricating Pinion

The hub is used in conjunction with the lubricating pinion. Lubricating oil can be channeled through special passages in the hub to the felt pinion.

Assembly Fixture for BZ Systems

The assembly fixture is used for aligning butt-jointed BZ guide rails. It includes a rack segment designed to engage with the racks on both sides of the joint for precise alignment.

Lubrication Options

| Code | Type | Description | Application |

|---|---|---|---|

| LN | Oil Protection | Light oil protection | Systems with continuous oil supply after installation |

| LG | Grease Protection | Light grease coating | Systems with continuous grease supply after installation |

| LV | Standard Grease | Full grease fill | General applications with manual lubrication |

| LO | Oil Lubrication | For centralized lubrication systems | Automatic lubrication systems |

Rack Lubrication Recommendations

- Preferred Method: Use lubricating pinion (BZR-xx-L) to automatically replenish grease to the rack

- Alternative Method: Periodic manual application of rack lubrication grease

- Recommended Lubricant: Kluber Microlube GL 261 or equivalent

- Lubrication Frequency: Adjust based on usage frequency and environmental conditions; generally recommended every 500 km travel or monthly

Selection Notes

- Drive pinion should be selected based on torque requirements and travel precision needs

- Higher tooth count results in longer travel per revolution, but also higher maximum transmissible torque

- Recommend using one lubricating pinion together with one drive pinion

- For high-speed applications, oil lubrication (LO) is recommended

- Additional sealing accessories recommended for dusty environments

- Accessories must be selected according to corresponding size specifications